Mold for rammed-earth construction

A technology for rammed earth construction and ramming construction, which is applied in the field of moulds for rammed earth construction, can solve the problems of easy damage, high moisture content of mixed raw soil, unsuitable continuous application of log moulds, etc., and achieves good durability and long service life. Long, quick disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

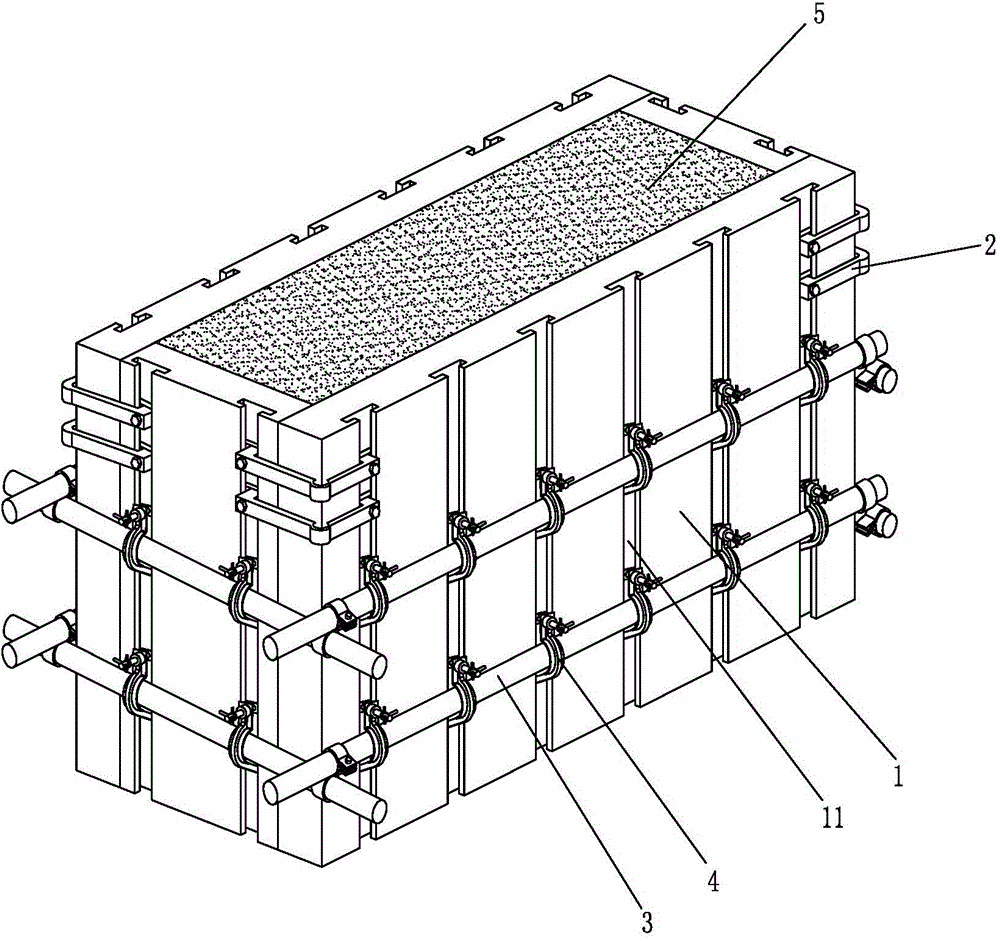

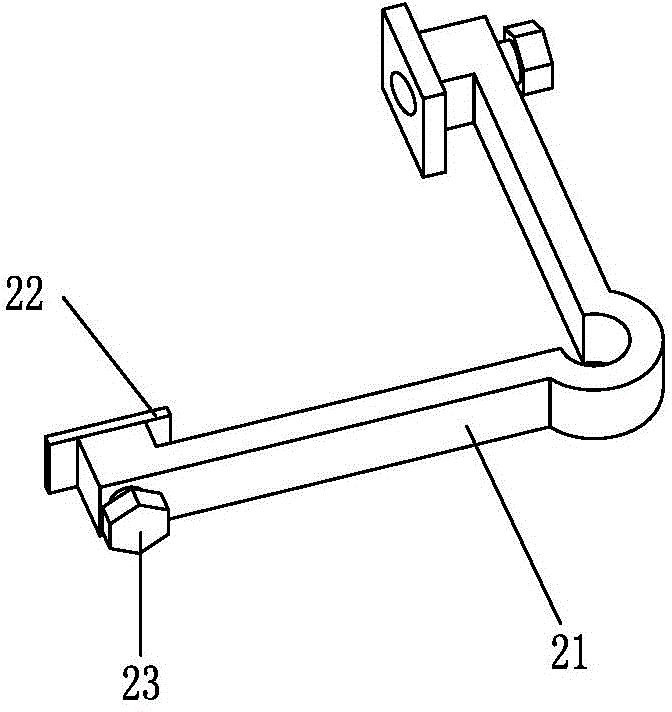

[0025] See Figure 1-Figure 4 As shown, a mold for ramming rammed earth buildings according to the present invention includes a plurality of plastic templates 1 and a plurality of connecting fasteners 2. Structure, the cross-section of the closed structure is rectangular, and its internal space forms a rammed cavity. Here, each plastic formwork 1 is a polyethylene hollow formwork, and its size and shape can be selected according to the actual tamping process requirements.

[0026] As a preference, it also includes a plurality of fixed pipes 3 and a plurality of pipe mold fasteners 4, the plurality of fixed pipes 3 are respectively fixed on the outer side of the closed structure by pipe mold fasteners 4, and the plurality of fixed pipe fasteners 4 are fixed to the outer surface of the closed structure. The tubes 3 are connected end to end in turn to form the annular reinforcement member of the closed structure. Here, each of the fixed pipes 3 is a steel pipe, which cooperates...

Embodiment 2

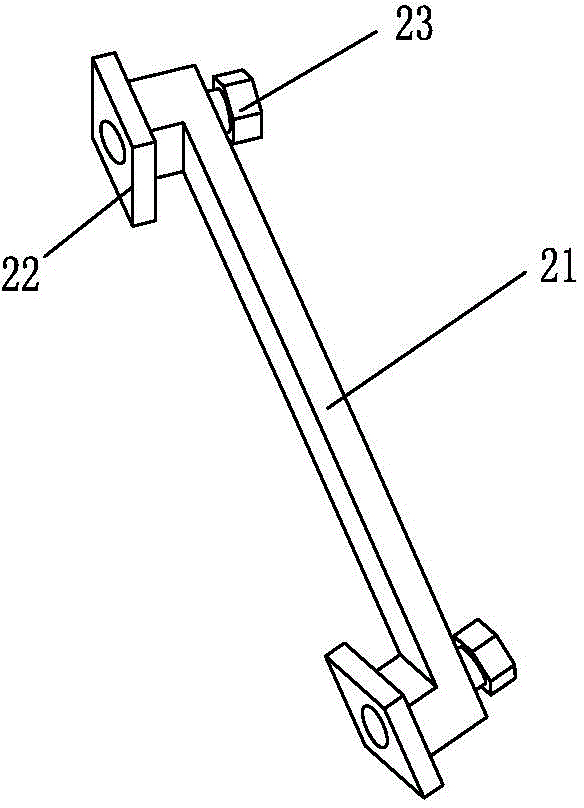

[0034] See Figure 5 As shown, a mold for ramming rammed earth buildings according to the present invention differs from Embodiment 1 in that the cross-section of the closed structure formed by assembling a plurality of plastic templates 1 is ring-shaped, specifically the ring shape is a circular shape. Font, that is, the closed structure is composed of two parts, the outer layer and the inner layer, wherein, the splicing mode of each plastic template of the outer layer part is the same as that of Embodiment 1, and the splicing mode of each plastic template of the inner layer part is also the same as that of embodiment 1. One is similar, but the structure of the connecting fastener 2 at the corner is different: the first block of the connecting fastener 2 is located on the outer side of the end of its L-shaped fastener body (in embodiment one, The first block 22 of the connecting fastener is arranged on the inner surface of the end of the L-shaped fastener body 21).

[0035] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com