Built-in rope net rammed earth wall body and construction method thereof

A technology of rammed earth wall and rope net, which is applied to building structures, walls, buildings, etc., can solve the problems of low seismic capacity of raw soil buildings, and achieve the effects of convenient construction, simple construction process, and improved limit displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

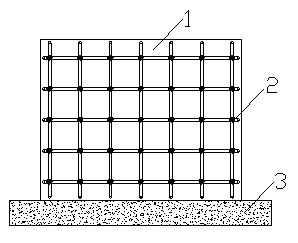

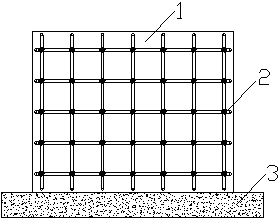

[0032] In this embodiment, the prototype size of the wall is 3300×2400×480mm, and the following construction techniques can be used in the construction process:

[0033] Step 1. According to the size and structural requirements of the rammed earth wall, select a brown rope with a diameter of about 20 mm, and prepare two pieces of rope nets with a small rectangular grid with a side length of about 300 mm. The final size of the rope net is 3300×2400 mm, and then the The rope net is soaked in water for use;

[0034] Step 2, excavating the foundation groove of the wall and tamping the foundation of the wall;

[0035] Step 3, ramming the formwork;

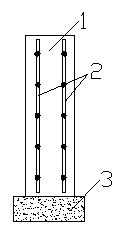

[0036] Step 4, according to the thickness and structural requirements of the rammed earth wall, place a piece of rope net at a position 120 mm away from the wall formwork, parallel to the formwork;

[0037] Step 5: Fill the formwork with raw soil layer by layer. Each layer of soil is about 150mm thick. Since the inner space of the for...

Embodiment 2

[0041] In this embodiment, the wall prototype size is 3300×2400×480mm, and the construction process can adopt the following construction process:

[0042] Step 1. According to the size and structural requirements of the rammed earth wall, select a brown rope with a diameter of about 20 mm, and prepare two pieces of rope nets with a small rectangular grid with a side length of about 300 mm. The size of the rope nets is selected as 4300×3400 mm (each end protrude from the wall about 500mm), and then soak the rope net in water for use;

[0043] Step 2, excavating the foundation groove of the wall body and tamping the foundation of the wall body. According to the thickness and structural requirements of the rammed earth wall, the bottom end of the rope net is buried in the wall foundation, and a piece of rope net is placed at a position 120 mm away from the outer side of the wall. The rope net surface is parallel to the outer surface of the rammed earth wall. The bottom end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com