Hammerblow tamper of excavator

An excavator and hammer force technology, which is applied in the field of rammed earth mechanisms, can solve the problems that construction machinery cannot meet the needs of compaction and compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

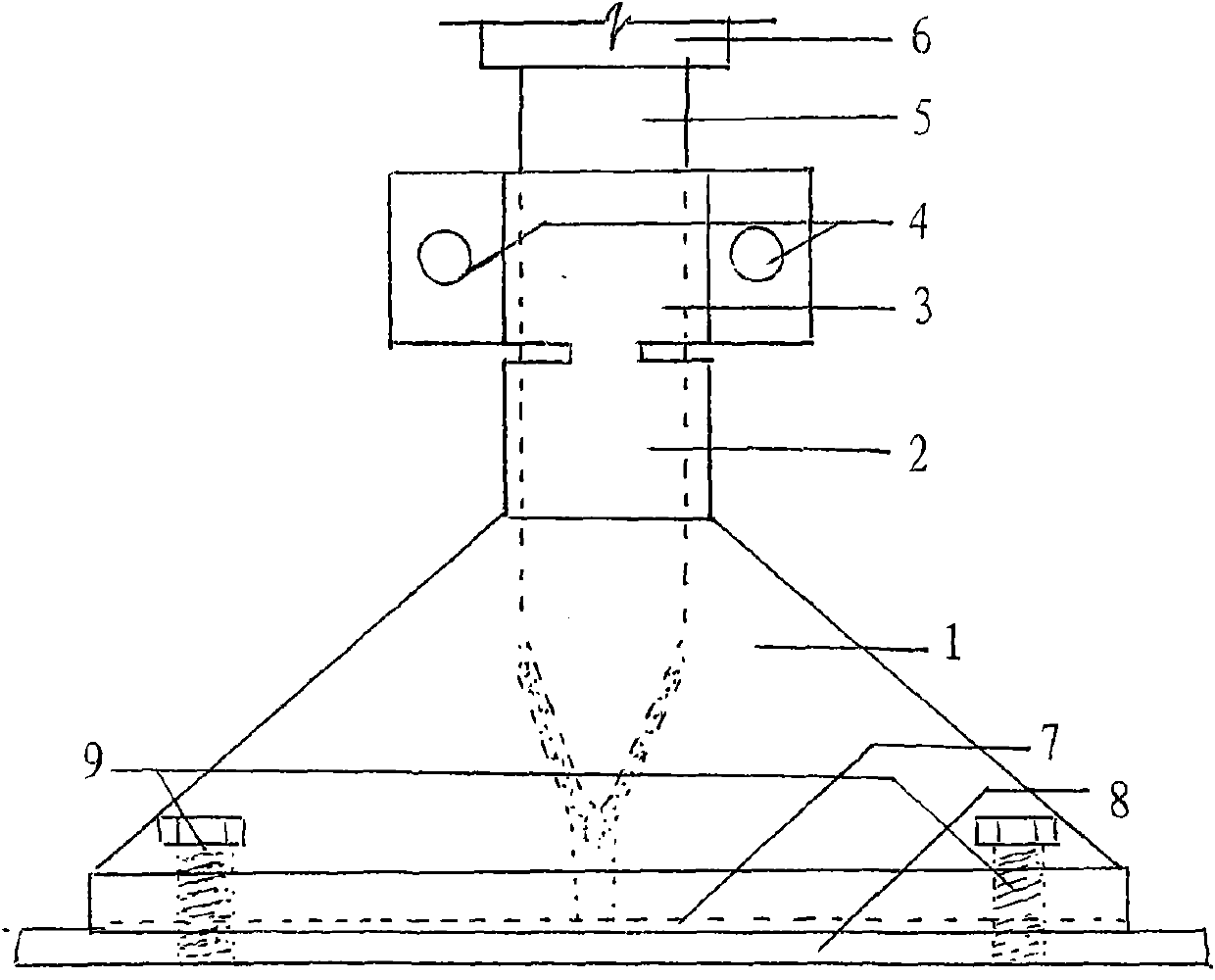

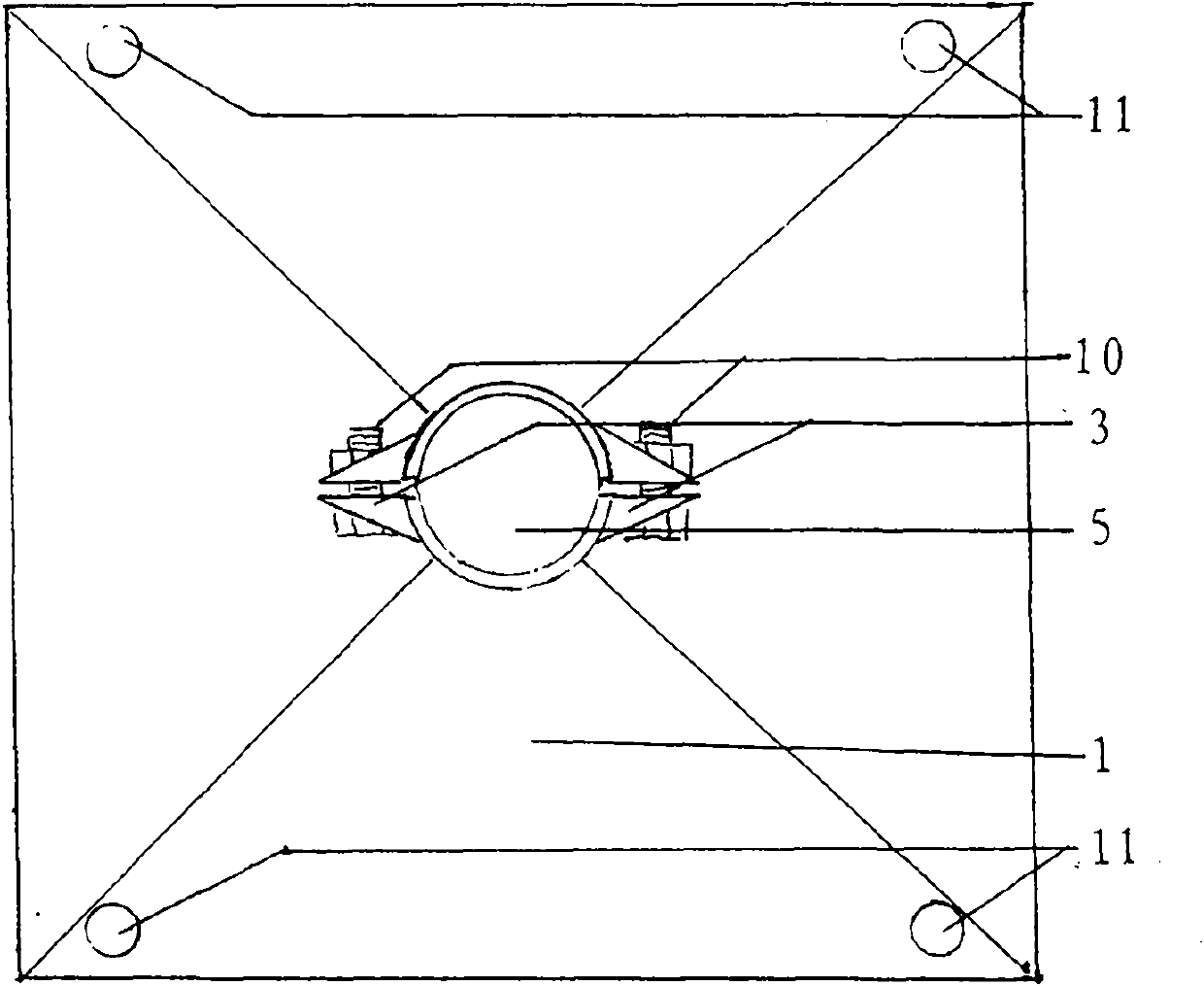

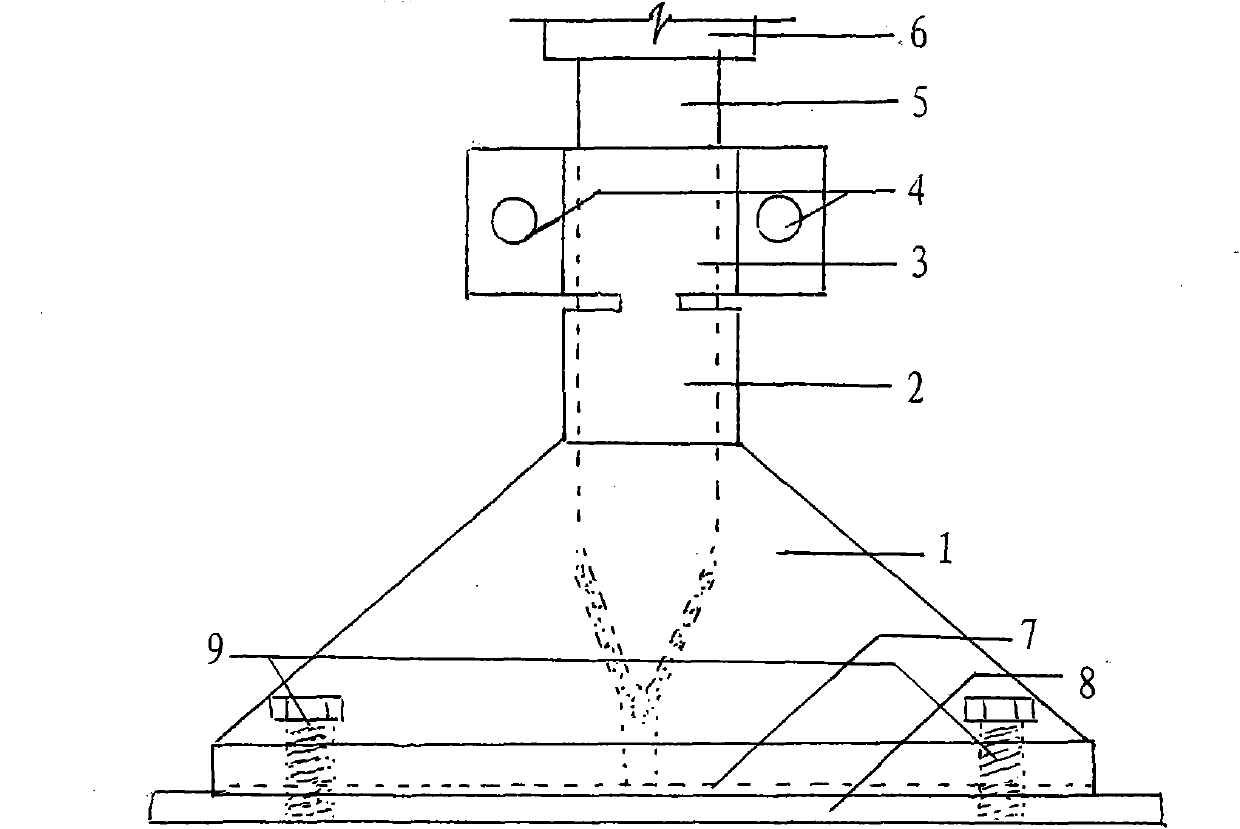

[0012] figure 1 The shown excavator hammer rammer is a ramming mechanism installed on the hydraulic breaker bit of the excavator. The main body 1 of the rammed earth disc made of cast steel can resist the huge destructive force of the breaker bit 5 and will It acts on earth and rock tamping. The steel pipe 2 and hoop 3 on the rammed earth plate, and the bolts 10 on both sides of the hoop pass through the middle of the hoop screw hole 4, so that the drill bit 5 of the breaking hammer can be fixed in the ramming body 1. The main machine of the breaking hammer 6 The huge hammering force generated during work is directly transmitted to the tamping body 1 by the drill bit 5, which can be used for compulsory hammering and compaction of earth and stone. Press in the soil process to prevent stones from slipping, as the increased rammed earth plate 8 can be connected with the upper rammed body 1 by screw holes 11 with bolts 9 when ramming the earth in a large area.

[0013] The excava...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com