A peanut oil residue grinder

A peanut oil residue and pulverizer technology, which is applied to presses, manufacturing tools, grain processing and other directions, can solve the problems of reducing the bagging efficiency of peanut oil residue and increasing fatigue, so as to prevent the peanut oil residue from being too large, prevent physical fatigue, reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

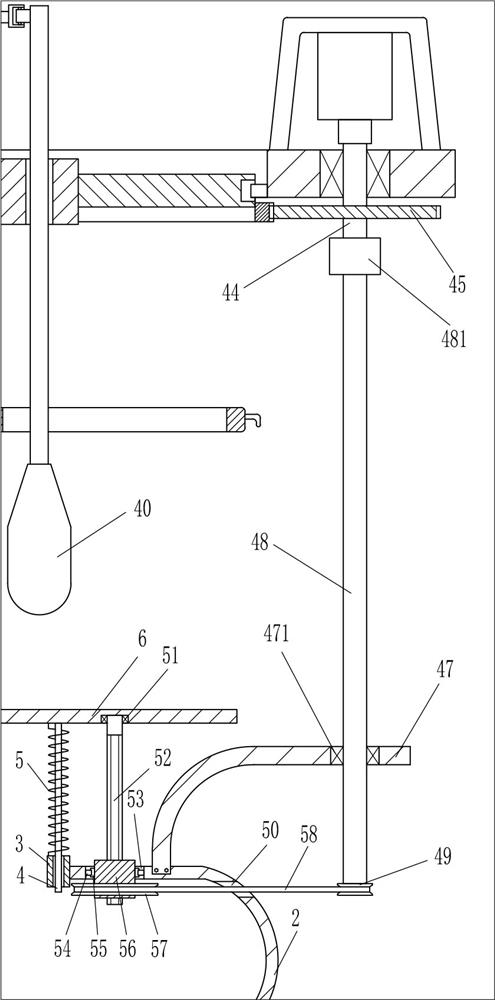

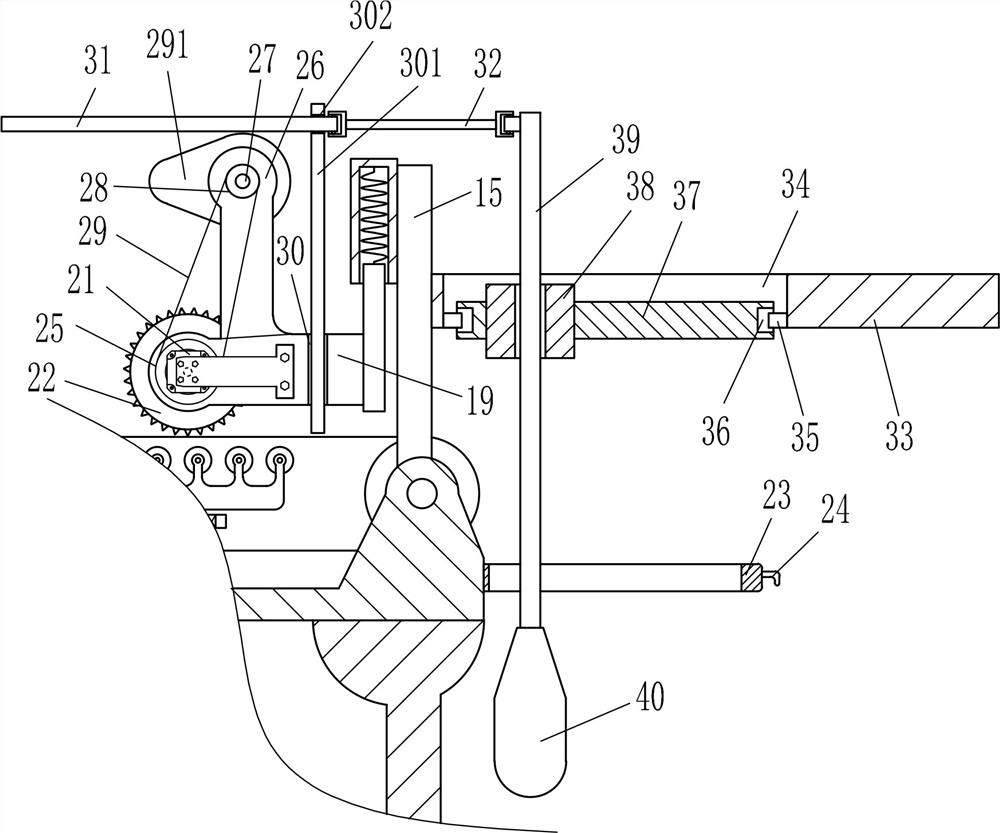

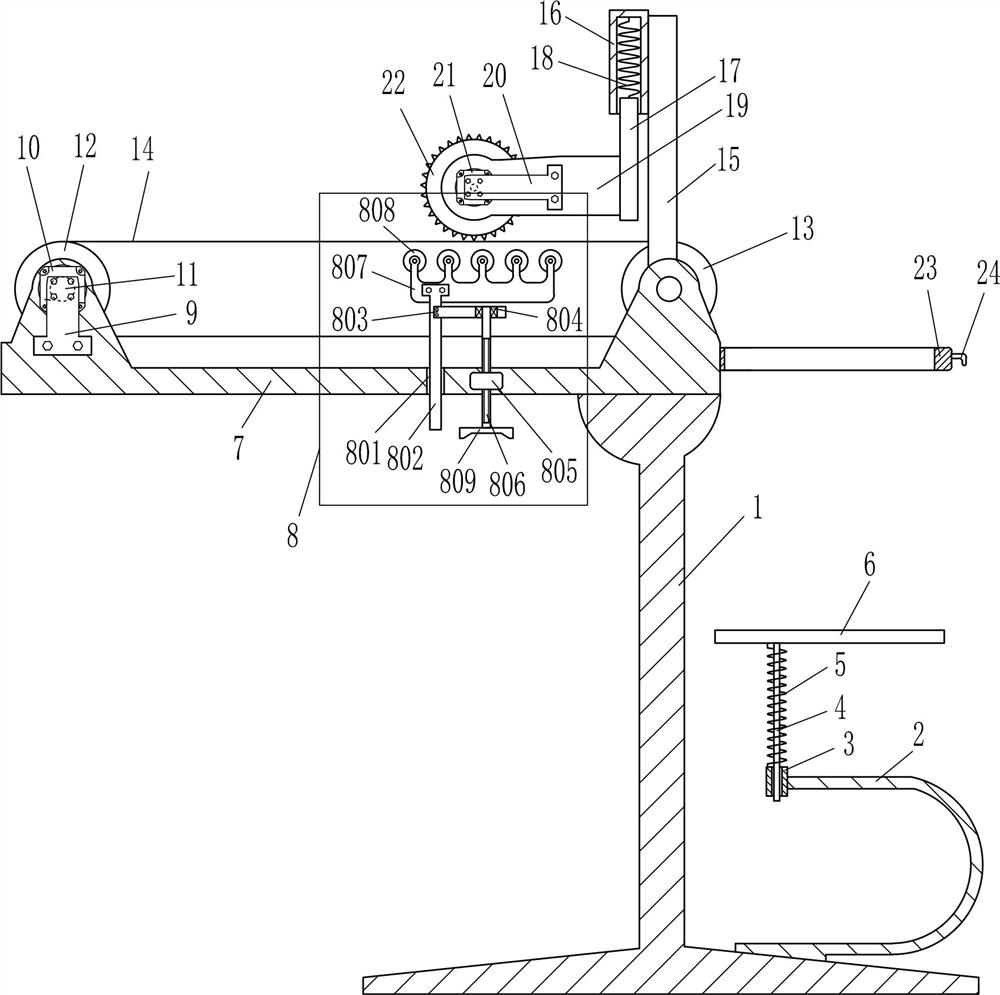

[0017] A kind of peanut oil residue pulverizer, such as figure 1 As shown, it includes a support 1, a first bracket 2, a first sliding sleeve 3, a first sliding rod 4, a first spring 5, a first support plate 6, a second support 7, a support device 8, and a second support plate 9. The first motor 10, the first rotating shaft 11, the first transmission wheel 12, the second transmission wheel 13, the transmission belt 14, the third bracket 15, the sliding tube 16, the second sliding rod 17, the second spring 18, the third support Plate 19, pole 20, second motor 21, crushing wheel 22, circular sleeve 23 and hook 24, the lower side right part of support 1 is equipped with the first support 2, the mode of support 1 is connected with the first by bolt The bracket 2 is connected, the first bracket 2 is installed with the first sliding sleeve 3, the first sliding sleeve 3 is slidingly provided with the first sliding rod 4 which plays a guiding role, and the top of the first sliding rod...

Embodiment 2

[0019] A kind of peanut oil residue pulverizer, such as figure 1 As shown, it includes a support 1, a first bracket 2, a first sliding sleeve 3, a first sliding rod 4, a first spring 5, a first support plate 6, a second support 7, a support device 8, and a second support plate 9. The first motor 10, the first rotating shaft 11, the first transmission wheel 12, the second transmission wheel 13, the transmission belt 14, the third bracket 15, the sliding tube 16, the second sliding rod 17, the second spring 18, the third support Plate 19, pole 20, second motor 21, pulverizing wheel 22, circular cover 23 and hook 24, the lower side right part of bearing 1 is equipped with the first support 2, and the first sliding sleeve is installed on the first support 2 3. The first sliding sleeve 3 is slidingly provided with a first sliding rod 4 that acts as a guide, and a first support plate 6 is installed on the top of the first sliding rod 4, and the first spring 5 that acts as a buffer i...

Embodiment 3

[0022] A kind of peanut oil residue pulverizer, such as Figure 1-2 As shown, it includes a support 1, a first bracket 2, a first sliding sleeve 3, a first sliding rod 4, a first spring 5, a first support plate 6, a second support 7, a support device 8, and a second support plate 9. The first motor 10, the first rotating shaft 11, the first transmission wheel 12, the second transmission wheel 13, the transmission belt 14, the third bracket 15, the sliding tube 16, the second sliding rod 17, the second spring 18, the third support Plate 19, pole 20, second motor 21, pulverizing wheel 22, circular cover 23 and hook 24, the lower side right part of bearing 1 is equipped with the first support 2, and the first sliding sleeve is installed on the first support 2 3. The first sliding sleeve 3 is slidingly provided with a first sliding rod 4 that acts as a guide, and a first support plate 6 is installed on the top of the first sliding rod 4, and the first spring 5 that acts as a buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com