Integrally-formed front fork and manufacturing method thereof

A production method and integrated technology, applied in steering mechanism, bicycle accessories, transportation and packaging, etc., can solve the problems of high production cost, complicated production process, difficult to withstand shearing force, etc., to reduce assembly and material costs, and simplify production. process, the effect of avoiding strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

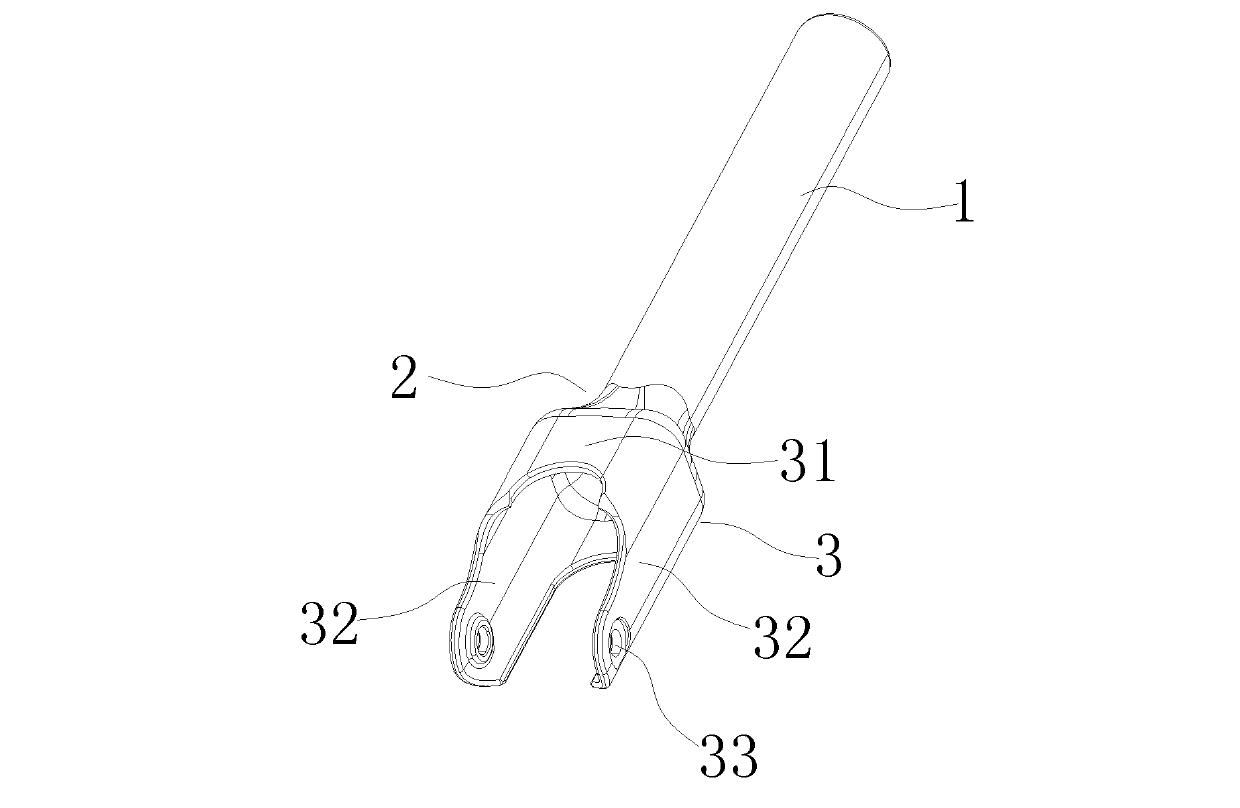

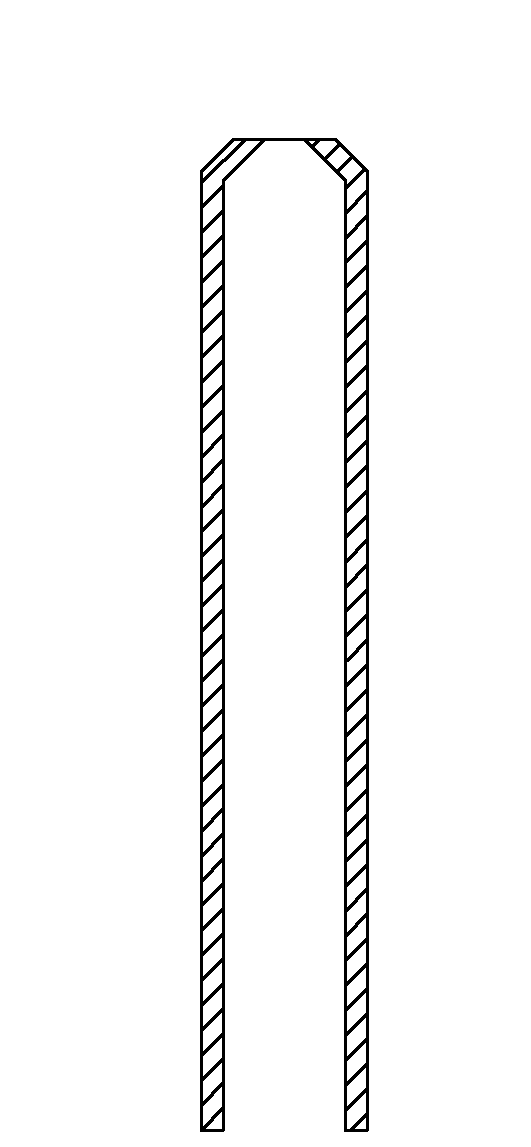

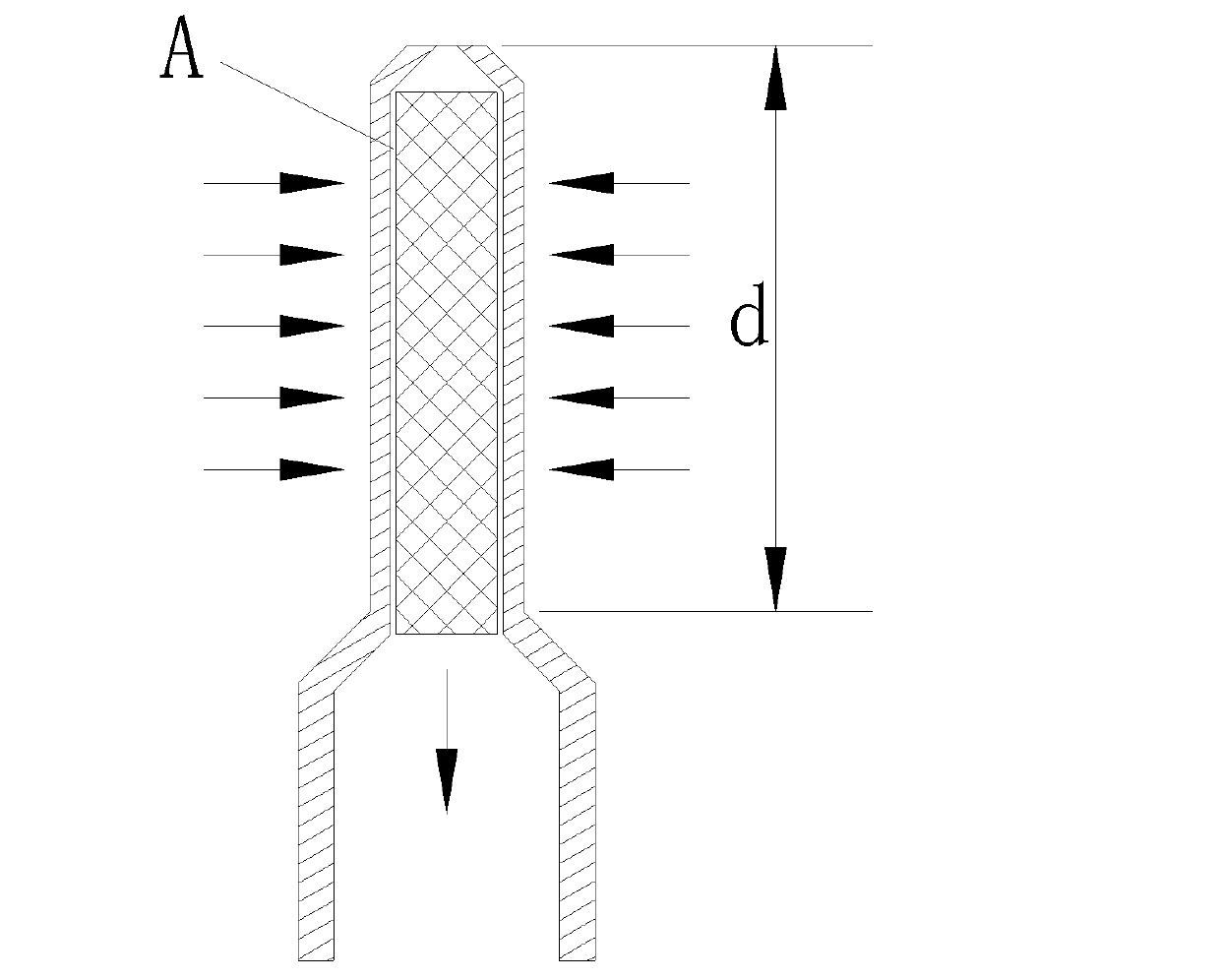

[0032] Such as figure 1 As shown, it is an integrally formed front fork of the present invention, including a steering tube 1, a connecting portion 2 and a front fork piece 3, the steering tube 1 is cylindrical, and the steering tube 1 and the front fork piece 3 are integrally formed on the connecting portion 2 respectively. The upper and lower ends, that is to say, the steering tube 1, the front fork piece 3 and the connecting part 2 are integrally formed. The front fork 3 includes a square tube portion 31 connected to the connecting portion 2 at its upper portion, and two plate-shaped portions 32 located on both sides of the square tube portion 31 , and the two plate-shaped portions 32 are opposite to each other. The area of the rectangle formed by the cross section of the square pipe portion 31 is greater than the area of the circle formed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com