Lever type connector

A connector and rod-type technology, which is applied in the direction of connection, parts of the connection device, fixed/insulated contact members, etc., can solve the problems of contact 101 falling off, difficult operation, and incomplete locking of contact 101, etc., to achieve The effect of preventing strength drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Next, a lever-type connector according to an embodiment of the present invention will be described with reference to the drawings.

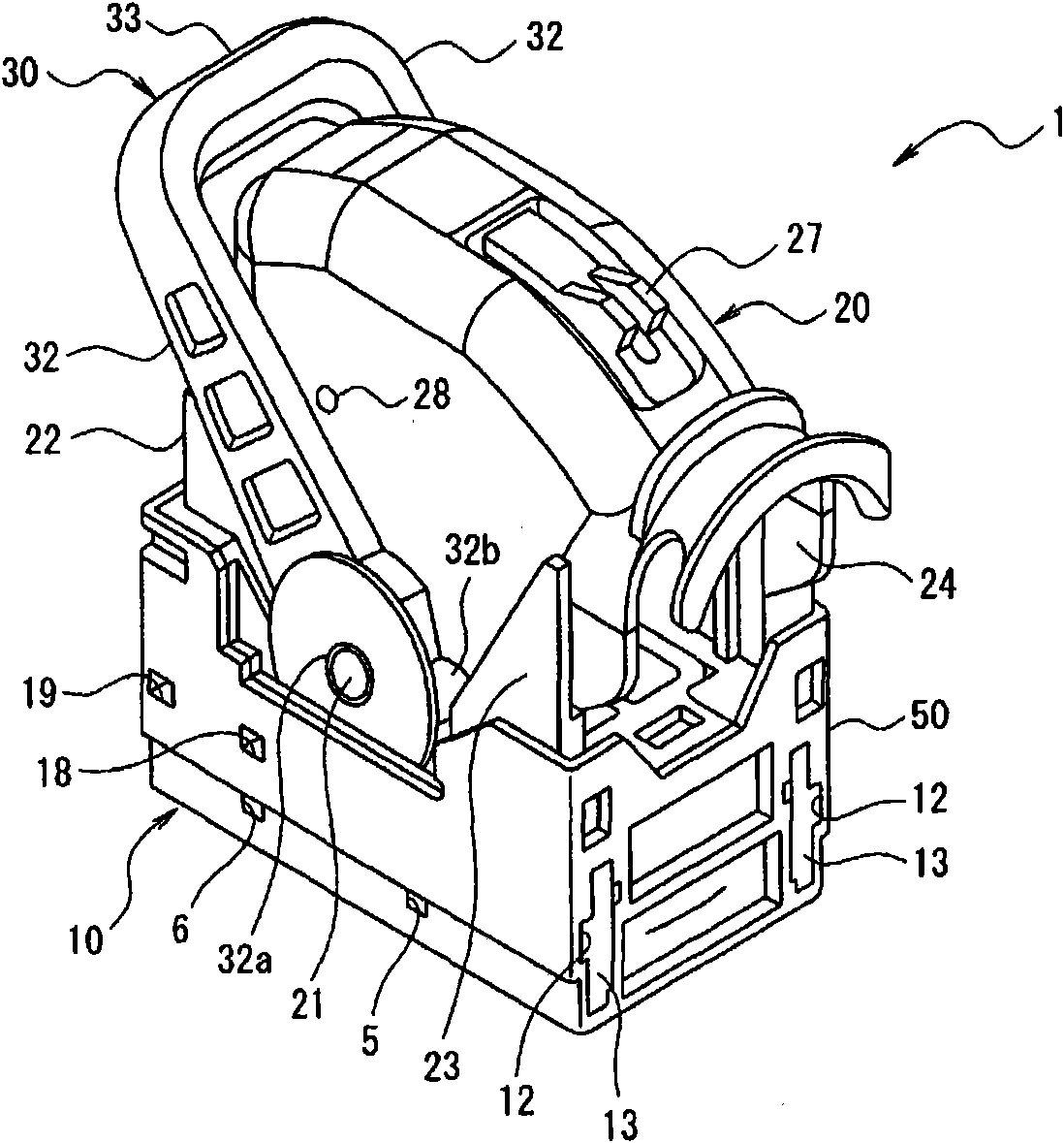

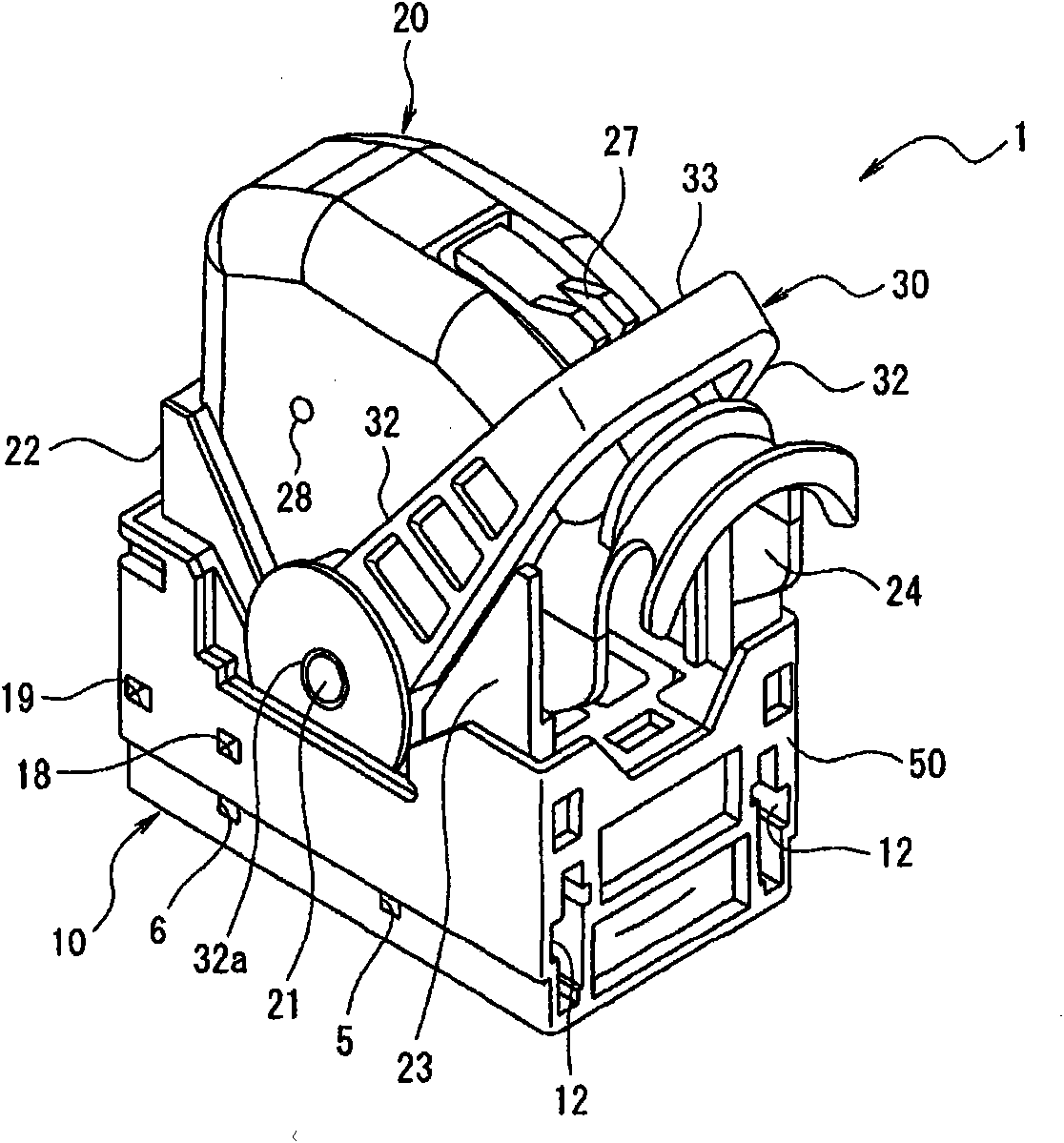

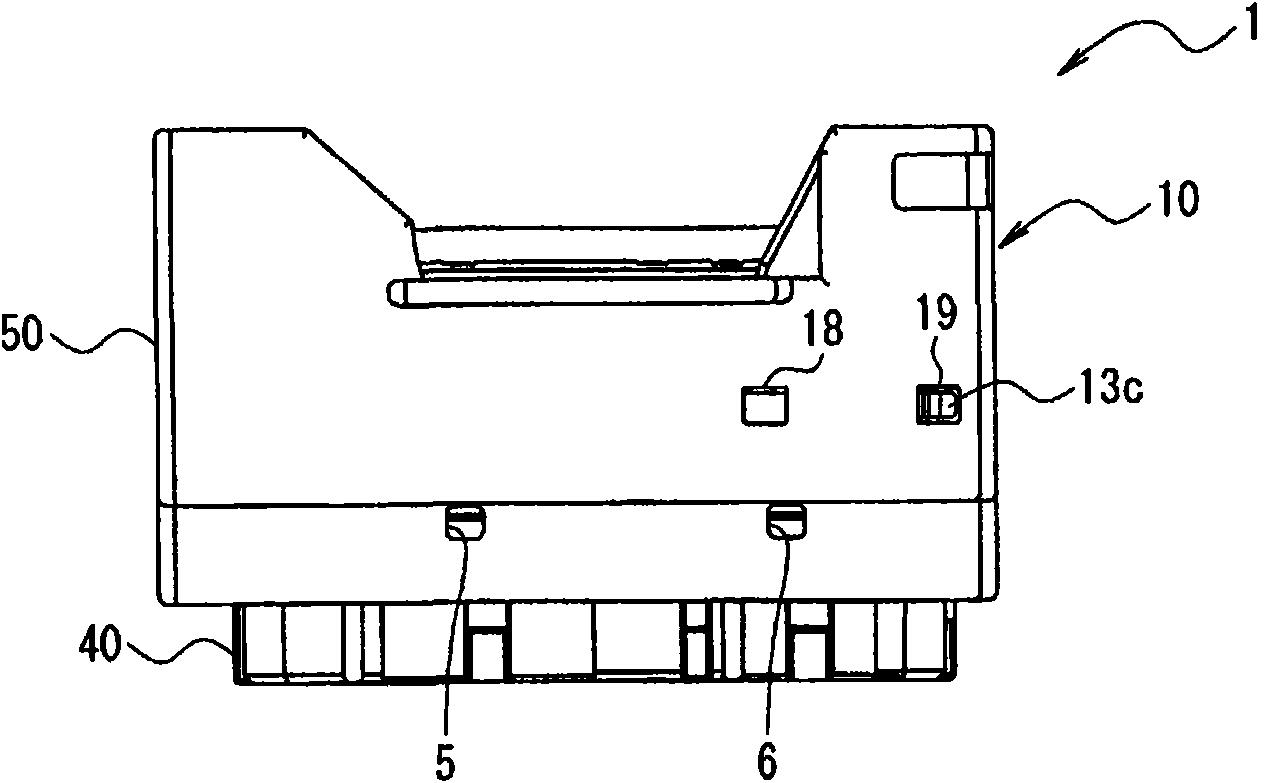

[0088] figure 1 It is a perspective view showing a state in which the rod of the rod-type connector according to the embodiment of the present invention is arranged at a fitting start position. figure 2 is displayed figure 1 It is a perspective view of a state in which the lever of the lever-type connector shown is arrange|positioned at the mating completion position. image 3 yes figure 1 A top view of the housing of the lever connector shown. Figure 4 yes image 3 Front view of the housing shown. Figure 5 is displayed will constitute image 3 A perspective view of the inner shell of the housing shown in an exploded state. Figure 6 It is a perspective view showing the housing with the slider at the fitting completion position. Figure 7 yes Figure 6 A cutaway view of the housing is shown. Figure 8 It is a perspective vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com