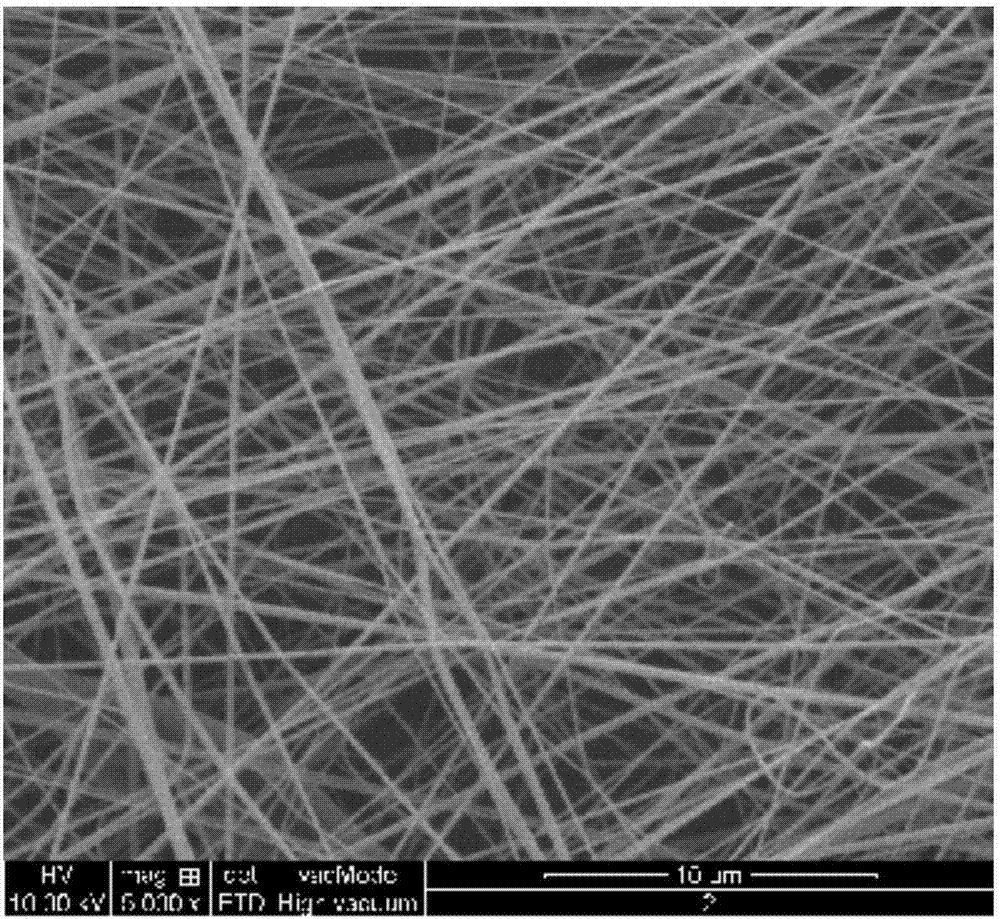

Cross-linked polyimide-based micro/nano fiber membrane and preparation method thereof

A nanofiber membrane and polyimide technology, applied in the field of fiber membranes, can solve the problems of poor mechanical properties, reduced membrane pore size, and excessive pore size, and achieve the effects of improved mechanical properties, reduced membrane pore size, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

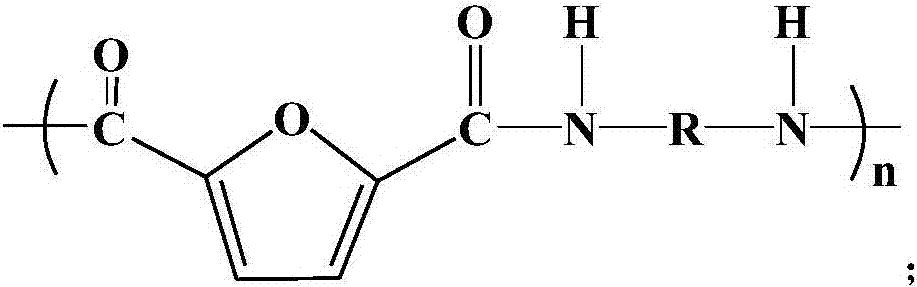

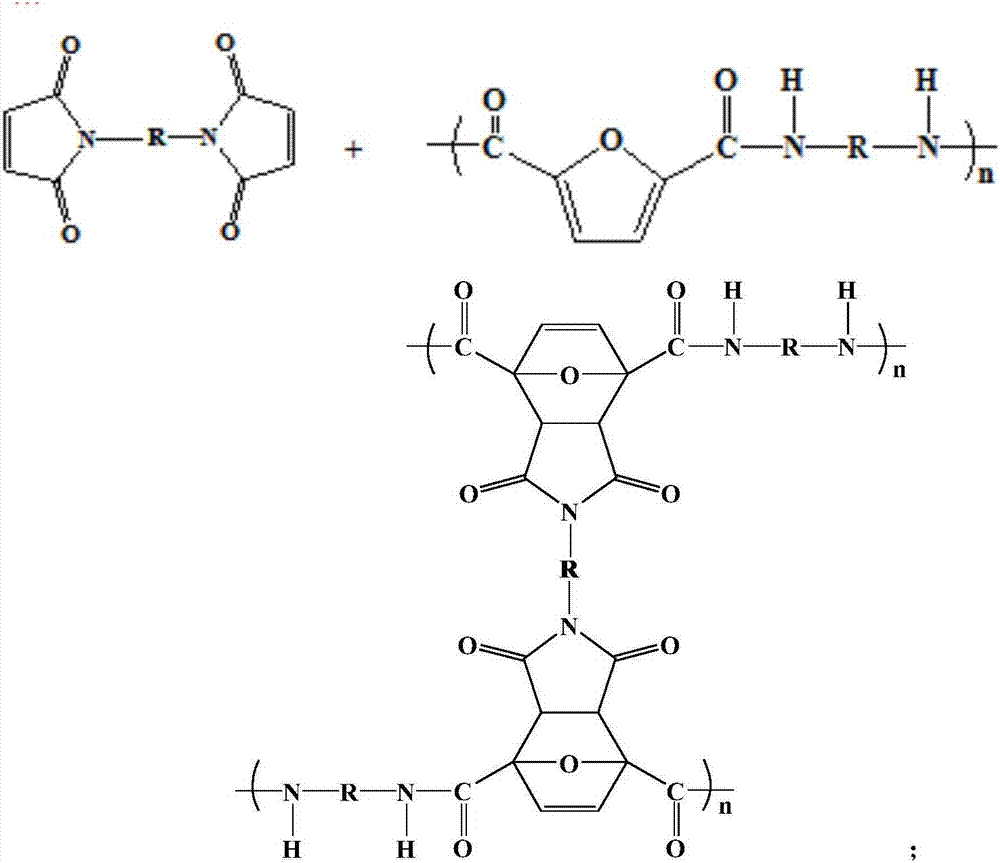

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of cross-linked polyimide-based micro / nano fiber membrane, the steps are as follows:

[0042] (1) Preparation of polyimide spinning solution: under nitrogen atmosphere, 3,3',4,4'-benzophenone tetraacid dianhydride and catalyst-concentration are 50wt% sodium hydroxide aqueous solution in N , dissolved in N-dimethylacetamide, at this time, the concentration of 3,3',4,4'-benzophenone tetraacid dianhydride in the reaction system is 24.15wt%, and then the diisocyanate mixture is added dropwise In the reaction system, react at 80°C for 6 hours to obtain a polyimide mixed solution, use N,N-dimethylacetamide to dilute the polyimide mixed solution, and vacuum defoam to obtain a 19wt% polyimide spinning Solution, the amount of sodium hydroxide added is 2% of the molar weight of 3,3',4,4'-benzophenone tetraacid dianhydride, the vacuum degassing vacuum is 0.08MPa, 3,3',4,4 The molar ratio of '-benzophenone tetraacid dianhydride and diisocyanate mixture is 1:1,...

Embodiment 2

[0056] A preparation method of cross-linked polyimide-based micro / nano fiber membrane, the steps are as follows:

[0057] (1) Preparation of polyimide spinning solution: under nitrogen atmosphere, 3,3',4,4'-benzophenone tetraacid dianhydride and catalyst-concentration are 50wt% sodium hydroxide aqueous solution in N , dissolved in N-dimethylacetamide, at this time, the concentration of 3,3',4,4'-benzophenone tetraacid dianhydride in the reaction system is 24.15wt%, and then the diisocyanate mixture is added dropwise In the reaction system, react at 80°C for 6 hours to obtain a polyimide mixed solution, use N,N-dimethylacetamide to dilute the polyimide mixed solution, and vacuum defoam to obtain a 19wt% polyimide spinning solution, the amount of sodium hydroxide added is 5% of the molar weight of 3,3',4,4'-benzophenone tetraacid dianhydride, the vacuum degassing vacuum is 0.08MPa, 3,3',4,4 The molar ratio of '-benzophenone tetraacid dianhydride and diisocyanate mixture is 1:1,...

Embodiment 3

[0066] A preparation method of cross-linked polyimide-based micro / nano fiber membrane, the steps are as follows:

[0067] (1) Preparation of polyimide spinning solution: under nitrogen atmosphere, 3,3',4,4'-benzophenone tetraacid dianhydride and catalyst-concentration are 50wt% sodium hydroxide aqueous solution in N , dissolved in N-dimethylformamide, at this time, the concentration of 3,3',4,4'-benzophenone tetraacid dianhydride in the reaction system is 20wt%, and then the diisocyanate mixture is added dropwise to the reaction In the system, react at 50°C for 7 hours to obtain a polyimide mixed solution, use N-methylpyrrolidone to dilute the polyimide mixed solution, and vacuum defoam to obtain a 15wt% polyimide spinning solution, sodium hydroxide The addition amount is 1% of the molar weight of 3,3',4,4'-benzophenone tetraacid dianhydride, the vacuum degree of vacuum defoaming is 0.08MPa, 3,3',4,4'-benzophenone The molar ratio of ketone tetraacid dianhydride and diisocyana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com