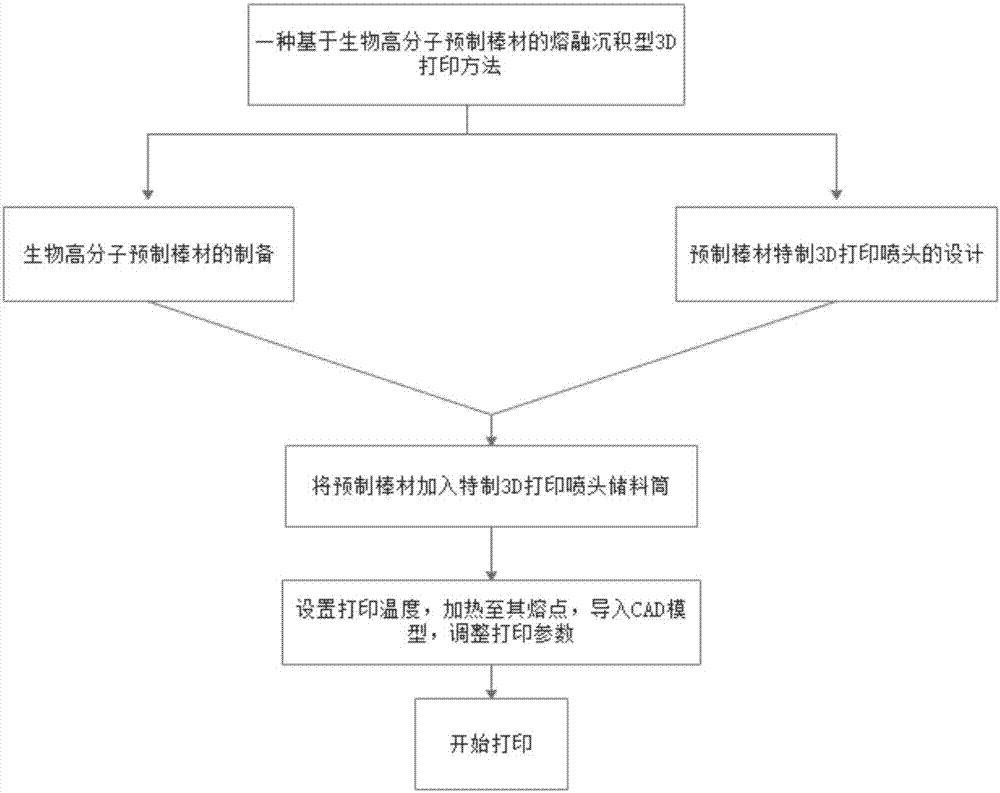

Fused deposition type 3D printing method based on biopolymer prefabricated bar

A biopolymer, 3D printing technology, used in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of printing consumables that are easily oxidized by moisture, affect continuous and stable printing, and break molecular bonds, and avoid the strength of the bar. Degradation or thermal degradation of polymer materials, ensuring high-precision high-quality printing, avoiding pollution and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

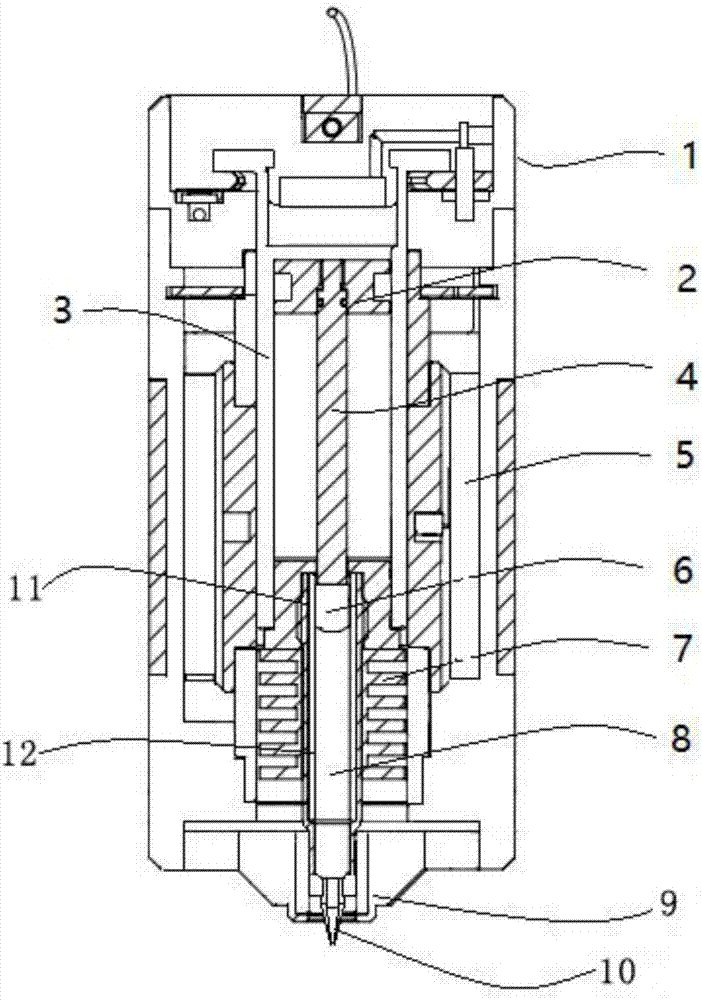

Method used

Image

Examples

Embodiment 1-1

[0040] 1) Take a certain amount of polylactide (PLA) particles and grind them with a pulverizer, and place them in a mortar for further grinding. Dry the ground materials in a vacuum dryer at room temperature for 24 hours and then use a 28-mesh sieve for sieving After processing, the obtained powder is ready for use.

[0041] 2) Take a unit volume of polylactide polymer material powder, measure its mass by an electronic balance to be 0.90g, and calculate the density of the powder to be 0.90g / cm 3 , According to the volume is 1.13cm 3 The mold calculates the mass of the sample to be 1.02g, and weighs a sample of the same mass with a balance.

[0042] 3) Put the weighed powder sample with sulfuric acid paper into a powder pressing mold with a diameter of 5mm, place the weighing mold with the sample powder on top of the hydraulic pressure, press 5Mpa and keep the pressure for 3 minutes until the pre-pressed sample becomes a cylindrical shape, and continue at a constant speed Press to ...

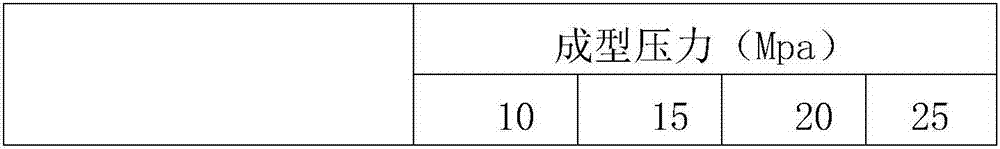

Embodiment 1-2~1-4

[0045] The molding pressure of step 3) in Example 1-1 was changed from 15Mpa to 10Mpa, 20Mpa, and 25Mpa, and the remaining experimental conditions were the same as those in Example 1-1, and the required preformed rod was finally prepared.

[0046] Table 1 The influence of forming pressure on the relative density of the bar and the wire-out time

[0047]

[0048]

[0049] Table 1 shows that when the molding pressure is lower than 15Mpa, although the thread-out time is short, its compressive strength is low, and the thread-out is accompanied by bubbles, which is prone to wire breakage and low molding accuracy. Above 15Mpa, the threading time is long and the material is easy to degrade. Therefore, the optimal molding pressure of the polylactide preformed rod in Example 1-1 of the present invention is selected to be 15Mpa. The molding pressure of other polymer material prefabricated rods can be determined according to its own properties.

Embodiment 1-5~1-9

[0051] The 5mm diameter mold in Example 1-1 was changed to 6mm, 7mm, 8mm, 9mm, and 10mm respectively, and the rest of the experimental conditions were the same as that of Example 1-1, and the required preform was finally prepared.

[0052] Table 2 The influence of the diameter of the bar on the printing and extrusion speed and the wire-out time

[0053]

[0054] Table 2 shows that the influence of bar diameter on bar extrusion speed and printing time is not obvious. It can be seen that the design freedom of bar specifications is relatively high, and it can be quantitatively designed according to clinical needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com