Framing system of studs and rails connected together by adapter members

a technology of adapter members and framing systems, applied in building reinforcements, walls, constructions, etc., can solve the problems of local creep, limited tolerances, and limited connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

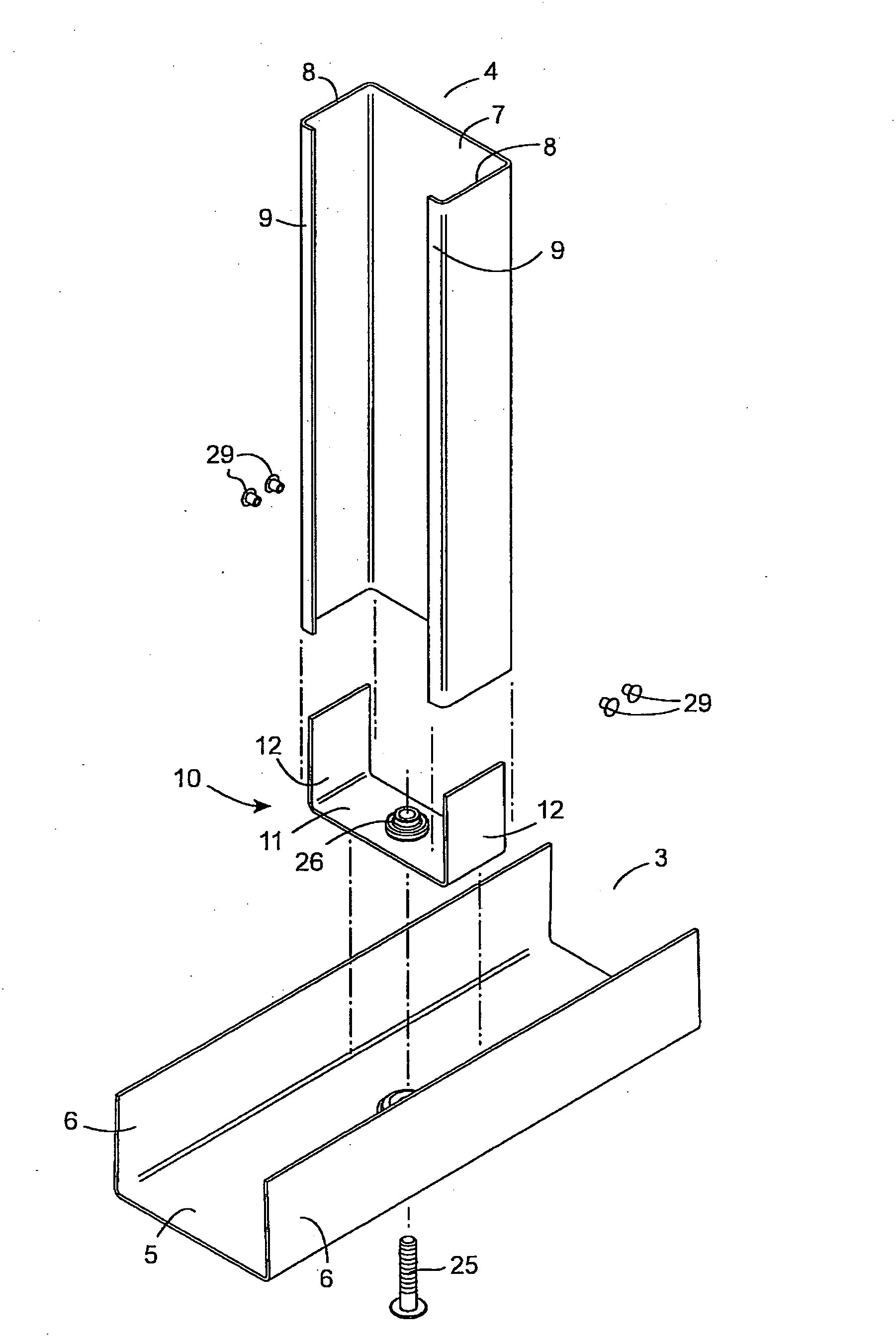

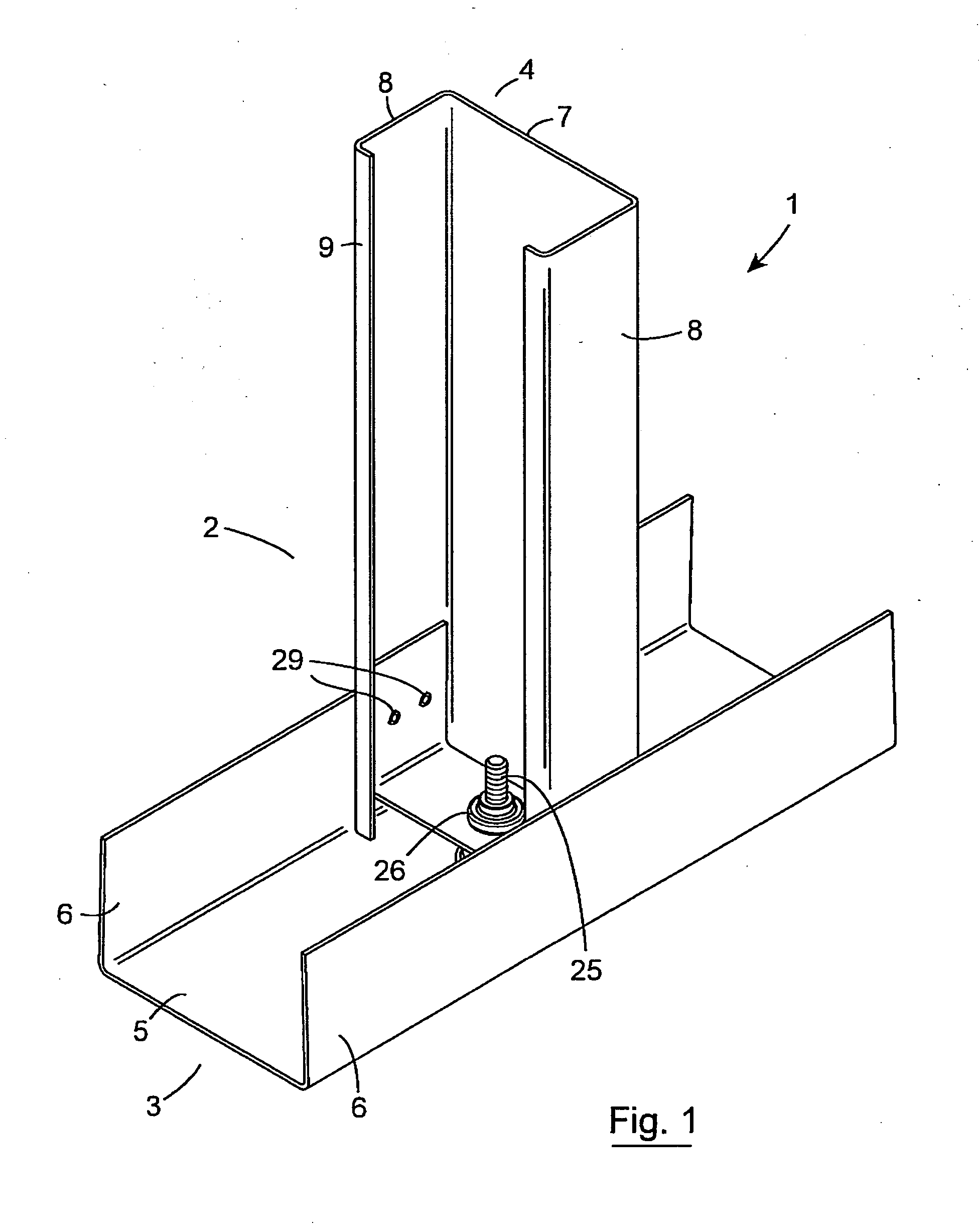

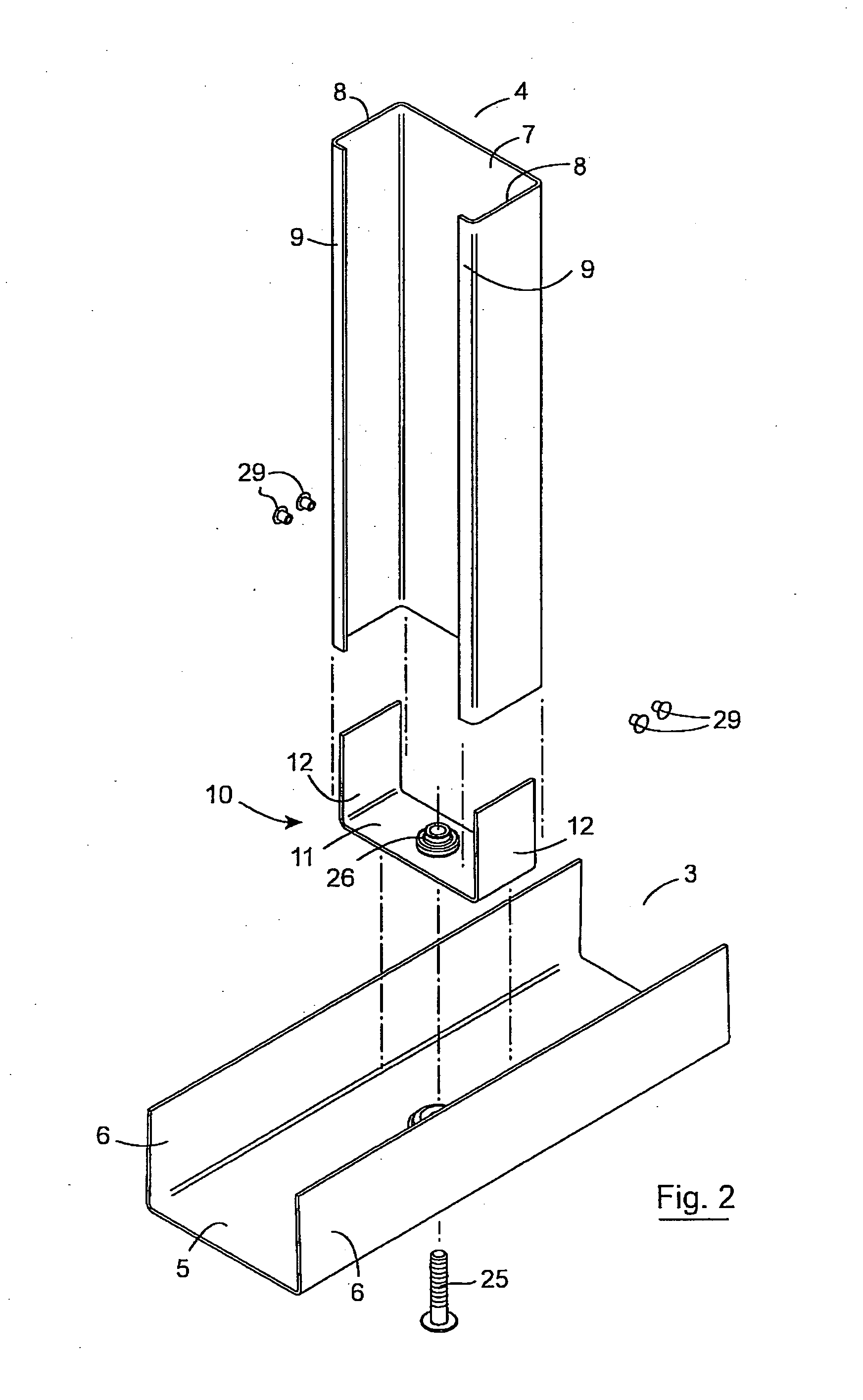

[0046]Referring to the drawings there is illustrated a structural framing system 1 according to the invention comprising a number of frame elements typically of metal, in this case steel sections, connected at joints 2. The frame elements in this case comprise track frame elements 3 and stud frame elements 4 which are interconnected to form the framing system.

[0047]The track frame element 3 is of rolled steel and comprises an elongated channel having a web 5, and side flanges 6 which extend continuously the length of the element 3. In this case the side flanges 6 are overbent. The overbent flanges 6 taper inwardly to the width of the stud to ensure a smooth joint between the stud and track frame elements.

[0048]The stud frame element 4 is also of rolled steel and comprises an elongated generally c-shaped lipped channel having a web 7, and side flanges 8 which extend continuously the length of the element. The side flanges 8 have inturned side lips 9.

[0049]The framing system comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com