Cutting-resisting yarn

A yarn and core yarn technology, applied in the field of cut-resistant yarn, can solve the problems of difficult to achieve high-density weaving, poor looping effect, high linear density, etc., and achieve light weight, improved cut resistance, aramid fiber The effect of high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

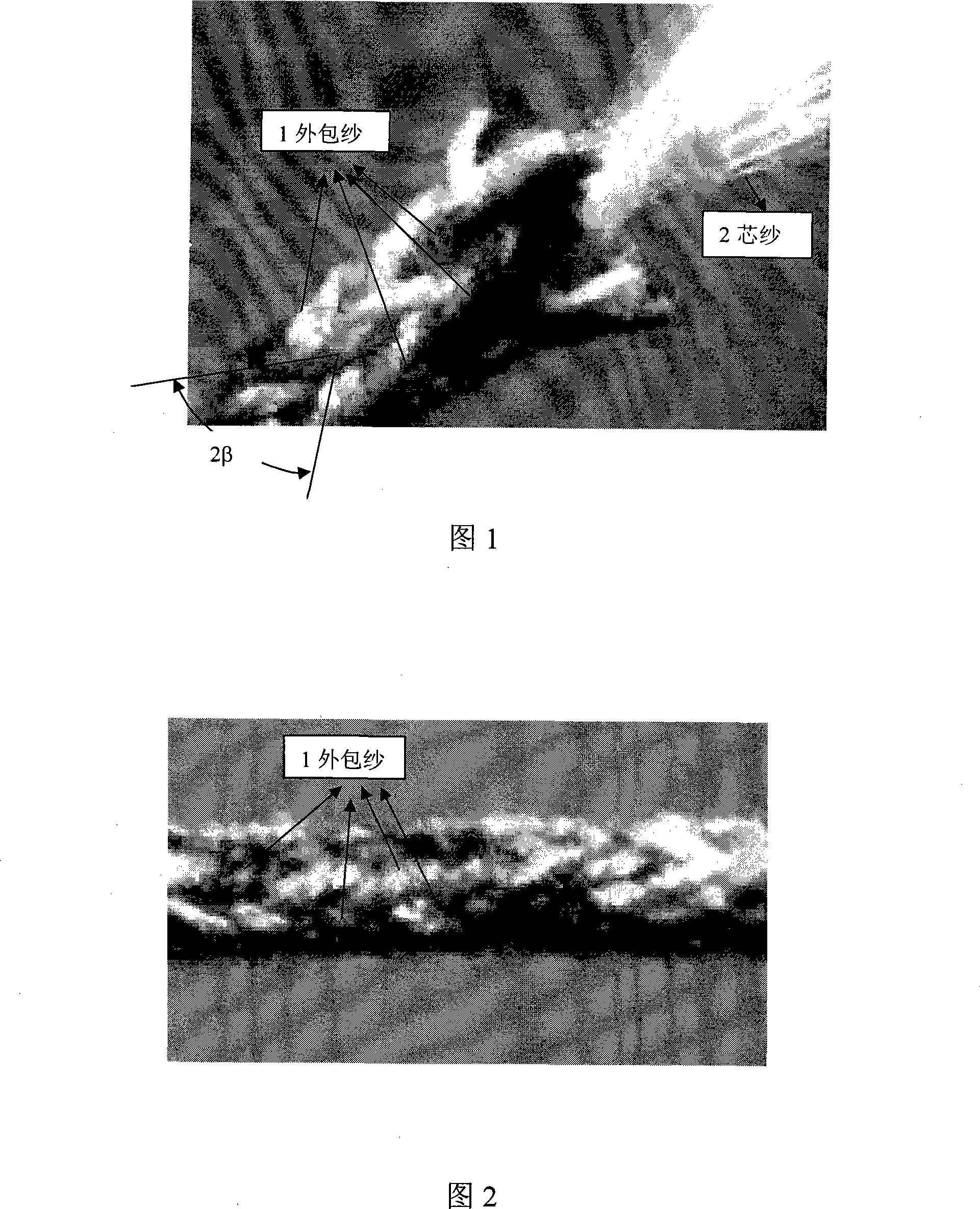

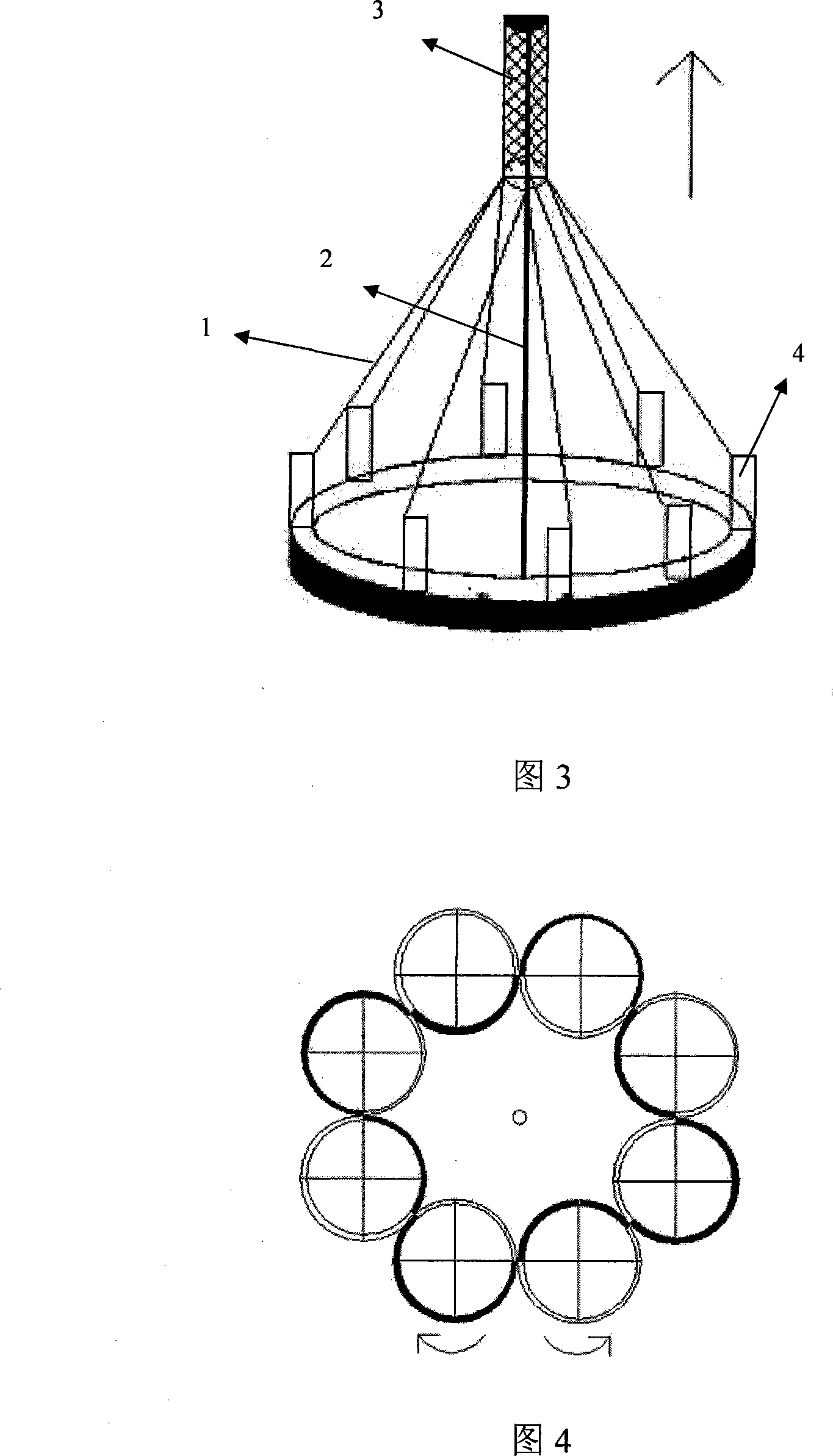

[0031] The high-strength polyethylene untwisted filament with a measured value of 1125 denier is the core yarn 2, and its breaking strength is 16 grams per denier; the aramid fiber twisted filament with a measured value of 264.4 denier is the outer covering yarn 1, and the twist is 24 twists per denier. 10 cm, the breaking strength is 18 g / denier; the volume ratio of the core yarn 2 and the outer covering yarn 1 is 0.25, adopting a forming device (two-dimensional knitting machine) with 8 yarn carriers 4 and a two-dimensional knitting machine with a braiding angle of 45°. The cut-resistant yarn 3 is produced by weaving through the dimensional weaving forming method.

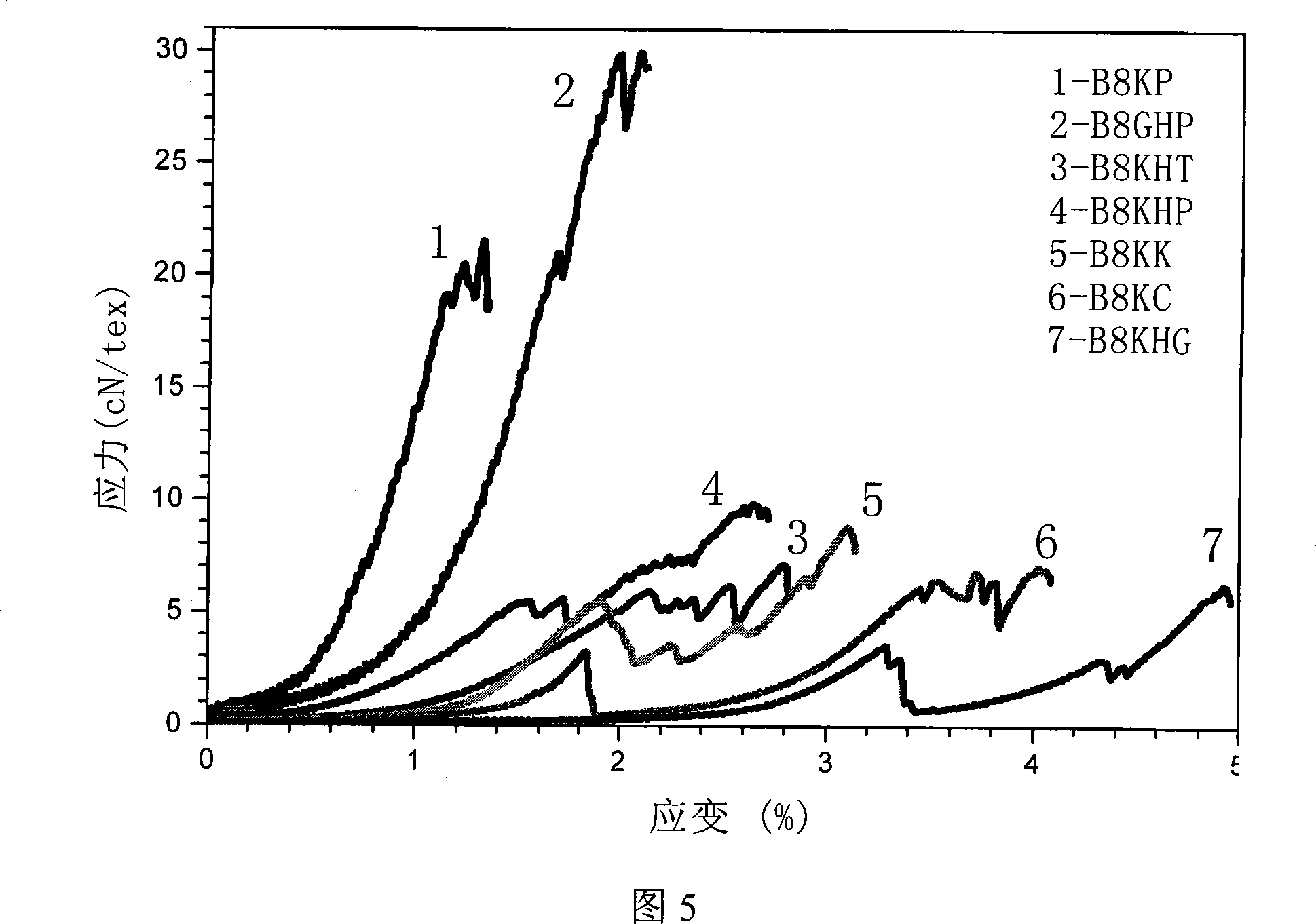

[0032] After testing, the formed cut-resistant yarn (see accompanying drawings 1 and 2) has good cut resistance or cut resistance (see curve 2 in Figure 5), and its short-cut short-crack strength has reached 30cN / Tex .

Embodiment 2

[0034] The high-strength polyethylene untwisted filament with a measured value of 1125 denier is the core yarn 2, and its breaking strength is 16 g / denier; the aramid fiber twisted filament with a measured value of 1420 denier is the outer covering yarn 1, and the twist is 21 twists per denier. 10 cm, the breaking strength is 17 g / denier, the volume ratio of the core yarn 2 and the outer covering yarn 1 is 0.1, and a two-dimensional knitting machine with eight yarn carriers 4 is used for two-dimensional knitting, and the knitting angle is 45°.

[0035] After testing, the formed cut-resistant yarn (see accompanying drawings 1 and 2) has good cutting resistance or cutting resistance (see curve 1 in Figure 7), and its cutting-resistant breaking strength reaches 22cN / Tex.

[0036] Table 1 Specification list of raw materials used in cut-resistant yarn research experiments

[0037] series

code name

Linear density (denier)

Twist ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com