Efficient mirror plane flatting agent for powder paint, preparation method and application

A technology of powder coating and leveling agent, applied in the direction of coating, can solve problems such as poor resin compatibility, and achieve the effect of improving compatibility, convenient use and improving quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

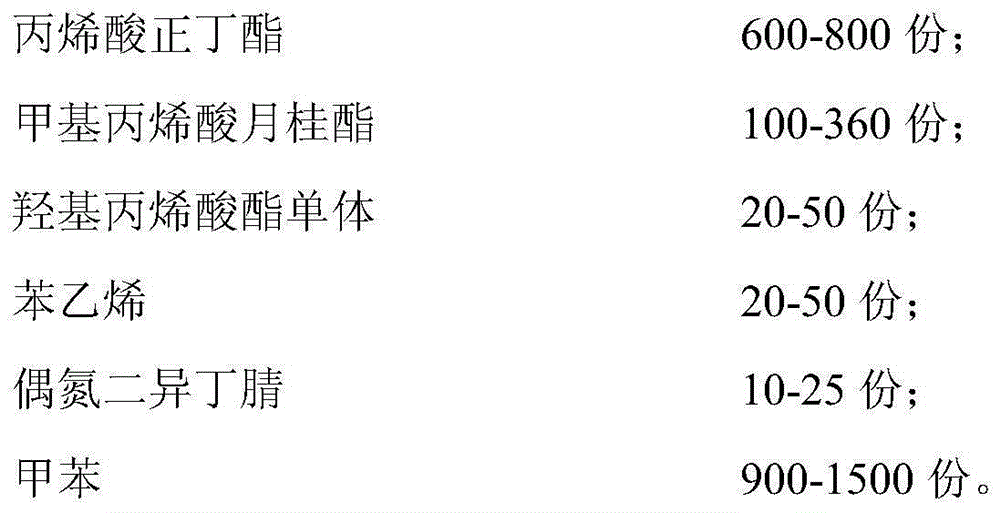

[0035] A high-efficiency mirror surface leveling agent for powder coatings, its raw material composition and quality are respectively:

[0036]

[0037] The preparation method of high-efficiency mirror surface leveling agent for above-mentioned powder coating, its steps are:

[0038] (1) Toluene with a total mass of 70-80% is sucked into the reaction kettle under negative pressure, and the temperature is raised and continuously stirred to a reflux state;

[0039] (2) Dissolve 90-99% of the total mass of azobisisobutyronitrile in 10-15% of the remaining total mass of toluene to obtain azobisisobutyronitrile mixture, and mix n-butyl acrylate, lauryl methacrylate, hydroxyl Mix the acrylate monomer and styrene evenly, add the azobisisobutyronitrile mixture and the reactant mixture prepared above dropwise to the reaction kettle under reflux, and finish dropping within 2-5 hours;

[0040] (3) Dissolve the remaining azobisisobutyronitrile in the remaining toluene to obtain azobis...

Embodiment 2

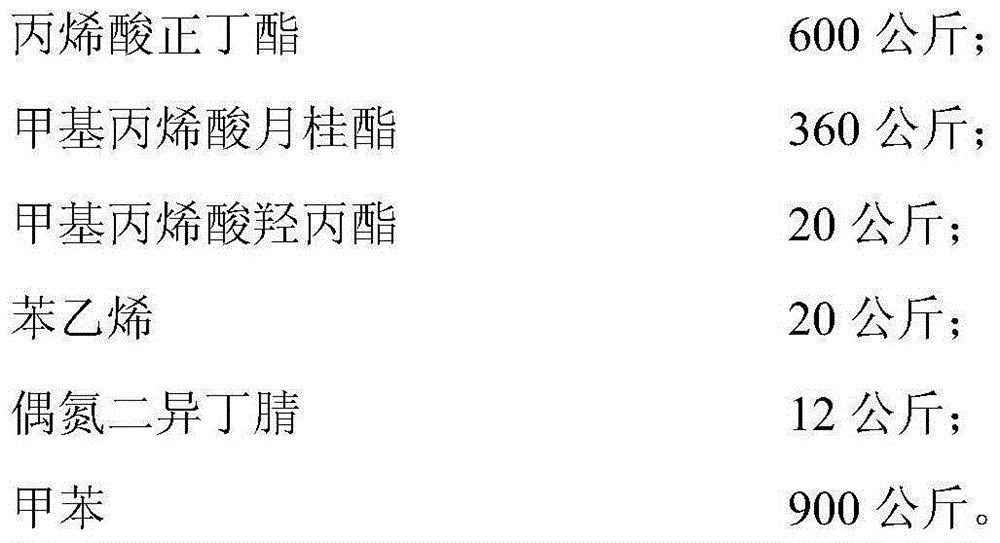

[0043] A high-efficiency mirror surface leveling agent for powder coatings, its raw material composition and quality are respectively:

[0044]

[0045] The preparation method of high-efficiency mirror surface leveling agent for above-mentioned powder coating, its steps are as follows:

[0046] (1) Toluene with a total mass of 70-80% is sucked into the reaction kettle under negative pressure, and the temperature is raised and continuously stirred to a reflux state;

[0047] (2) Dissolve 90-99% of the total mass of azobisisobutyronitrile in 10-15% of the remaining total mass of toluene to obtain azobisisobutyronitrile mixture, and mix n-butyl acrylate, lauryl methacrylate, hydroxyl Mix the acrylate monomer and styrene evenly, add the azobisisobutyronitrile mixture and the reactant mixture prepared above dropwise to the reaction kettle under reflux, and finish dropping within 2-5 hours;

[0048] The hydroxy acrylate monomer is one or more of hydroxyethyl acrylate, hydroxyethyl...

Embodiment 3

[0052] A high-efficiency mirror surface leveling agent for powder coatings, its raw material composition and quality are respectively:

[0053]

[0054] The preparation method of the high-efficiency mirror surface leveling agent for the above-mentioned powder coating, its steps are the same as in Example 1.

[0055] Practical application effect and test situation of leveling agent of the present invention:

[0056] 1, in order to check the actual application effect of the present invention, first the leveling agent of the present invention is mixed evenly with fumed silicon dioxide, and the specific operation is: take by weighing 90g of the leveling agent obtained in Examples 1, 2, and 3, and add it to 40g In fumed silica, mix and disperse at high speed in a high-speed crushing tank for 2 minutes after stirring evenly. Leveling agent 2, leveling agent 3. Then according to the general formula, this solid leveling agent 1,2,3 is added in the powder coating, make formula 1, ...

PUM

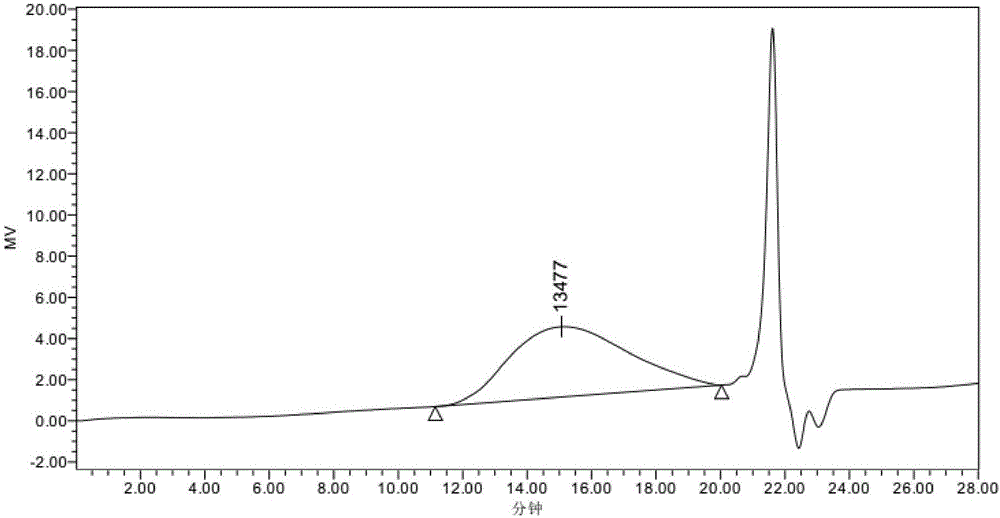

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com