Acrylic acid microgel emulsion having automatic restoration function and preparation method thereof

A self-healing, acrylic technology, applied in the direction of coating, etc., can solve the problems of high VOC emission, poor sagging and mechanical properties, no self-healing function, etc., to achieve improved acid and solvent resistance, excellent performance, and high solid content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

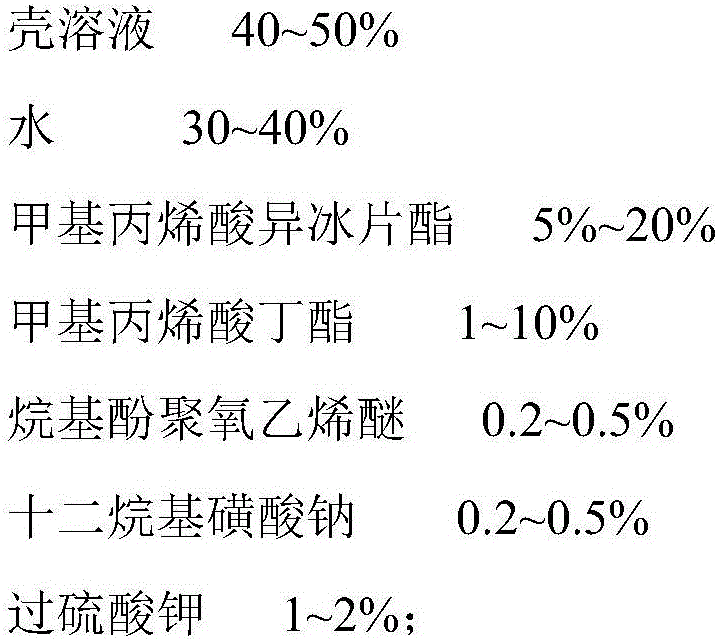

[0041] A kind of acrylic acid microgel emulsion with self-healing function, it is characterized in that: comprise shell and core, the composition of described shell and each component mass fraction are:

[0042]

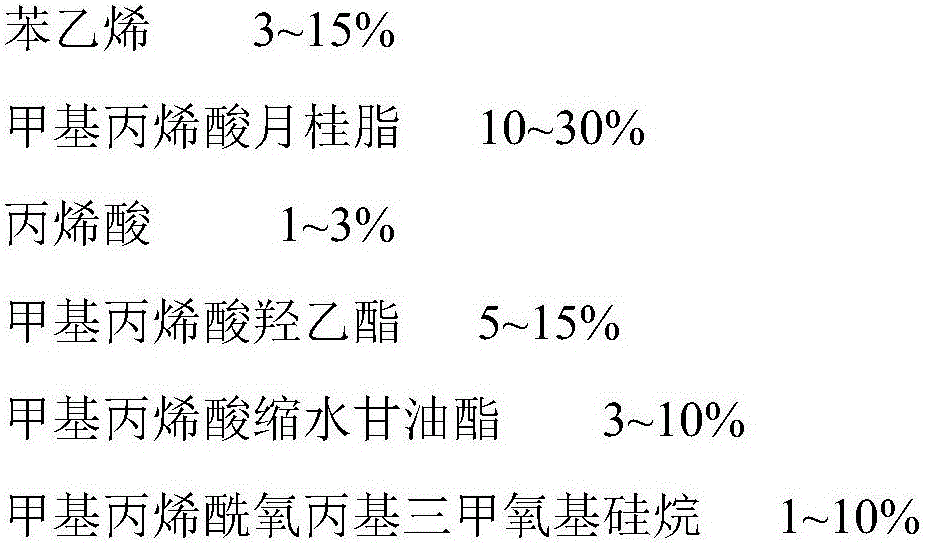

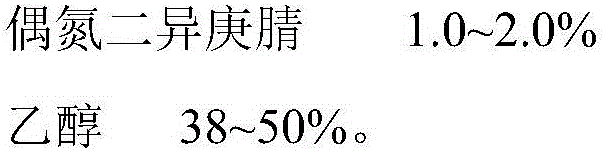

[0043] The composition of described core and each component mass fraction are:

[0044]

[0045] The solid content of the acrylic microgel emulsion in this example is 45%.

[0046] The preparation method of above-mentioned acrylic acid microgel emulsion is:

[0047] (1) adding 47% ethanol in proportion to the reactor and heating to reflux state;

[0048](2) 9% styrene, 10% lauryl methacrylate, 1% acrylic acid, 15% hydroxyethyl methacrylate, 3% glycidyl methacrylate, 10% methacryloxypropyl trimethoxy The mixture solution was obtained after mixing silane and 1.5% azobisisoheptanonitrile, and the mixture solution was added dropwise to the reactor within 3 hours. After the dropwise addition, it was reacted for 1 hour and then added dropwise with 3% ethanol and 0....

Embodiment 2

[0055] A kind of acrylic acid microgel emulsion with self-healing function, it is characterized in that: comprise shell and core, the composition of described shell and each component mass fraction are:

[0056]

[0057] The composition of described core and each component mass fraction are:

[0058]

[0059]

[0060] The solid content of the acrylic microgel emulsion in this example is 42%.

[0061] The preparation method of above-mentioned acrylic acid microgel emulsion is:

[0062] (1) adding 45% ethanol in proportion to the reactor and heating to reflux state;

[0063] (2) 3% styrene, 30% lauryl methacrylate, 2% acrylic acid, 8% hydroxyethyl methacrylate, 4% glycidyl methacrylate, 4% methacryloxypropyl trimethoxy After mixing silane and 0.5% azobisisoheptanonitrile to obtain a mixture solution, the mixture solution was added dropwise to the reactor within 3 hours, and after the dropwise addition, reacted for 1 hour and then added dropwise 3% ethanol and 0.5% azo...

Embodiment 3

[0070] A kind of acrylic acid microgel emulsion with self-healing function, it is characterized in that: comprise shell and core, the composition of described shell and each component mass fraction are:

[0071]

[0072] The composition of described core and each component mass fraction are:

[0073]

[0074] The solid content of the acrylic microgel emulsion in this example is 40%.

[0075] The preparation method of above-mentioned acrylic acid microgel emulsion is:

[0076] (1) adding 35% ethanol in proportion to the reactor and heating to reflux state;

[0077] (2) 15% styrene, 26% lauryl methacrylate, 3% acrylic acid, 5% hydroxyethyl methacrylate, 10% glycidyl methacrylate, 1% methacryloxypropyl trimethoxy The mixture solution was obtained after mixing base silane and 1.5% azobisisoheptanonitrile, and the mixture solution was added dropwise to the reactor within 3 hours. After the dropwise addition, 3% ethanol and 0.5% azobis Isoheptanonitrile was kept reacting fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com