Preparing method of PDLC (polymer dispersed liquid crystal) dimming glass film

A light-adjustable glass film and thin film technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of high cost and difficult glass film production process, and achieve the effect of increasing yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment one: resin content is 20%, because resin content drops, other two monomers will increase, hydroxypropyl methacrylate increases to 35%, o-phenylphenoxyethyl acrylate 35%, photoinitiator 5%, lauryl methacrylate 5%, mixed with 65% liquid crystal.

[0040] The result is:

[0041] First: due to the decrease of the resin and the decrease of the adhesiveness, it is easy to open the glue between the two layers of ITO;

[0042] Second: The content of o-phenylphenoxyethyl acrylate increases, causing the refractive index of the polymer to be greater than that of the liquid crystal, which will cause the light transmittance of the PDLC to decrease after the saturation voltage is applied.

Embodiment 2

[0043] Embodiment two: the hydroxypropyl methacrylate content drops to 15%, and the resin content increases to 45%, while o-phenylphenoxyethyl acrylate 30%, photoinitiator and lauryl methacrylate content are constant, then Then mix with 65% liquid crystal.

[0044] The result is:

[0045] First: the viscosity of the resin increases to be greater than that of the liquid crystal, and the grid in the polymer where the liquid crystal is precipitated after curing is too dense, and the voltage increases significantly. In addition, the low content of hydroxyacrylic acid is also the main reason for the high voltage.

[0046] Second: the refractive index of the prepolymer and the liquid crystal do not match, and the on-state transmittance decreases.

Embodiment 3

[0047] Embodiment three: the o-phenylphenoxyethyl acrylate content is reduced by 15%, the resin content does not increase and is still 40%, the hydroxypropyl methacrylate content increases to 35%, and the photoinitiator and lauryl methacrylate content do not increase. Change, and then mix with 65% liquid crystal.

[0048] The result is:

[0049] The refractive index of polymer is smaller than that of liquid crystal, and the light transmittance increases with the increase of voltage and there is never an optimal transmittance platform. It is a recipe for failure.

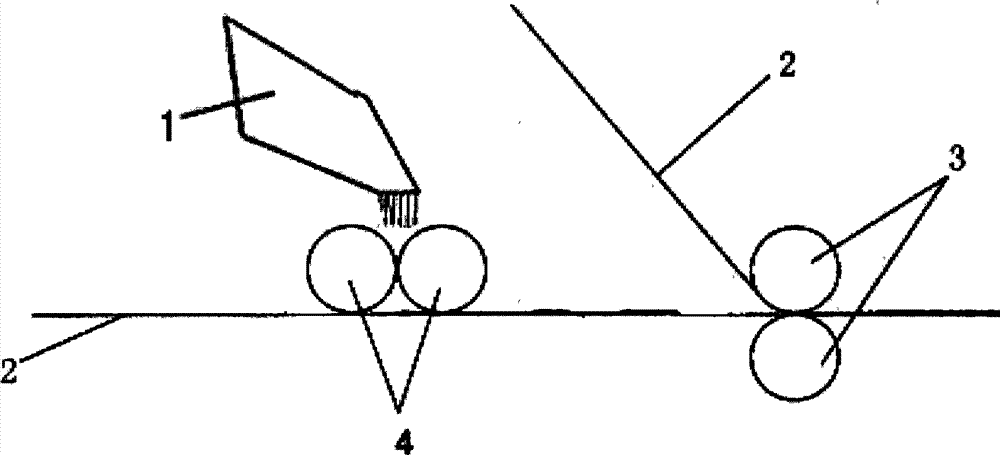

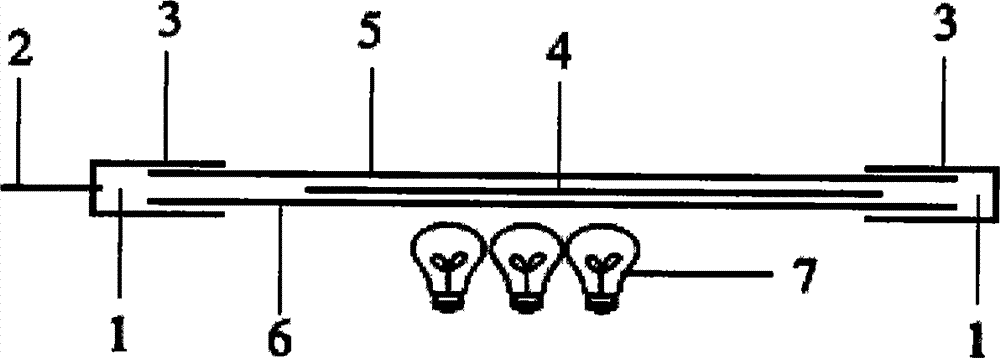

[0050] The preparation process of PDLC dimming glass film is as follows:

[0051] Step d, coating and pressing;

[0052] Please combine figure 1 As shown, the raw materials are added to the coating press machine, and the feeding tank 1 on the coating press machine evenly coats the raw materials in the middle of two layers of ITO films 2, so that the pressing distance is 20um, and the raw materials are coated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com