Aqueous concoction, aqueous polymer emulsion prepared from same and application thereof

A formulation, water-based technology that can be used in coatings and other directions to solve problems such as performance impairment, poor adhesion to plastic substrates, and insufficient hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

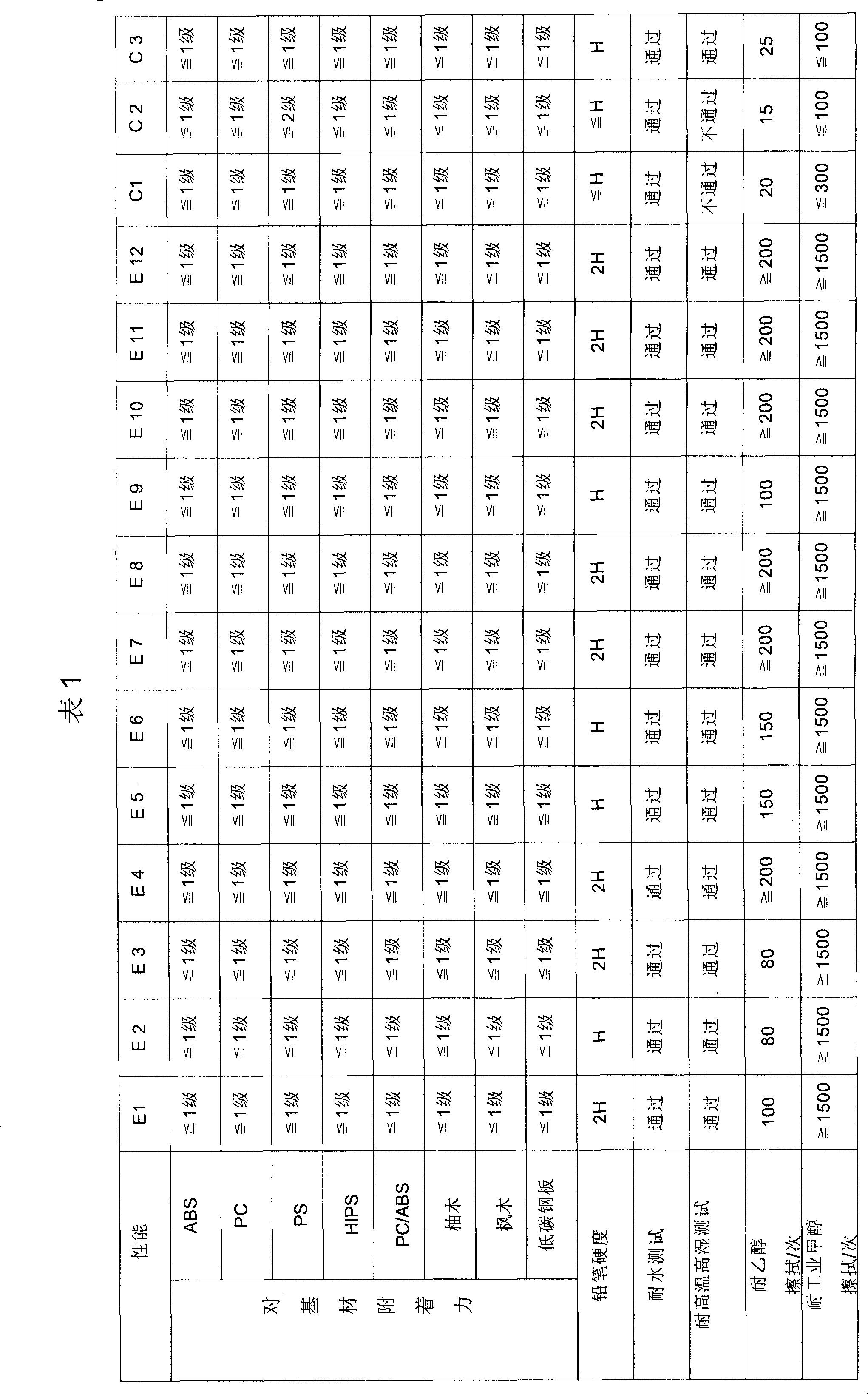

Examples

Embodiment 1

[0072] Example 1 (E1):

[0073] Add 280g of water, 1.4g of AE-300, 5.2g of M-10S into the reaction flask. 297.89g methyl methacrylate, 72.75g isobornyl methacrylate, 46.46g butyl acrylate, 48.5g hydroxyethyl methacrylate, 9.7g-1,6 hexanediol diacrylate (HDDA), 9.7 g methacrylic acid, 11.05 g AE-300, 8.08 g M-10S and 158.87 g water were stirred to make a pre-emulsion. The temperature of the reaction bottle was raised to 80-85°C, and 33.15g of pre-emulsion and 6g of ammonium persulfate aqueous solution (6wt% aq) were added to control the internal temperature to not exceed 85°C. When the temperature starts to drop to the set temperature (70-85°C), start to drop the remaining pre-emulsion and 34g ammonium persulfate aqueous solution synchronously for 1-6 hours, and control the internal temperature at the set temperature throughout the process. After the dropwise addition is completed, keep the temperature at 80-85°C for 1-4 hours. Cool down to below 40°C, add ammonia water to n...

Embodiment 2

[0074] Example 2 (E2):

[0075] Add 280g water, 1.4g EFS-980L 1.0g AE-300, 5.2g UCAN-1 into the reaction flask. 282.0g of isobornyl methacrylate, 15.04g of methyl methacrylate, 72.75g of butyl acrylate, 62.35g of hydroxyethyl methacrylate, 48.5g of 1,6-hexanediol diacrylate (HDDA), 9.7g methacrylic acid, 2.06g EFS-980L, 4.53g AE-300, 15.04g UCAN-1 and 158.87g water were stirred to make pre-emulsion. The temperature of the reaction flask was raised to 80-85°C, and 66.55g of pre-emulsion and 12g of ammonium persulfate aqueous solution (6wt% aq) were added to control the inner temperature not to exceed 85°C. When the temperature starts to drop to the set temperature (70-85°C), start to drop the remaining pre-emulsion and 28g ammonium persulfate aqueous solution synchronously for 1-6 hours, and control the internal temperature at the set temperature throughout the process. After the dropwise addition is completed, keep the temperature at 80-85°C for 1-4 hours. Cool down to belo...

Embodiment 3

[0076] Embodiment 3 (E3):

[0077] 280g water, 7.7g ER-30, 1.67g SR-10, 0.5g sodium bicarbonate were added to the reaction flask. 219.0g methyl methacrylate, 100.0g isobornyl methacrylate, 33.0g butyl acrylate, 40g hydroxyethyl methacrylate, 8.0g methacrylic acid, 15.38g ER-30, 3.33g SR-10 and 252.64g of water was stirred to make a pre-emulsion. The temperature of the reaction bottle was raised to 80-85°C, and 67.12g of pre-emulsion and 7.5g of ammonium persulfate aqueous solution (6.7wt% aq) were added to control the internal temperature to not exceed 85°C. When the temperature begins to drop to the set temperature (referring to 70-85°C), start to add the remaining pre-emulsion and 22.5g of ammonium persulfate aqueous solution synchronously, and the dropping time is 1-6 hours. The whole process controls the internal temperature at the set temperature . After the dropwise addition is completed, keep the temperature at 80-85°C for 1-4 hours. Cool down to below 40°C, add AMP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com