Preparation method of optical adhesive, liquid optical adhesive and curved-screen optical tape

A technology of optical adhesive and photoinitiator, which is applied in the directions of adhesives, non-polymer organic compound adhesives, pressure-sensitive films/sheets, etc., can solve the problems such as the inability to meet the bonding requirements of curved touch screens, and achieves a simple and easy preparation method. , high reliability requirements, the effect of suppressing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention also provides a method for preparing a liquid optical adhesive, which includes the following steps: stirring the raw materials of the above-mentioned optical adhesive at a temperature of 30-50° C. for 2-6 hours. During the stirring process, the rotation speed can be controlled between 20-600r / min. The stirring time can be selected according to the stirring speed and the stirring amount. After the stirring is completed, the vacuum is drawn, and the uncured adhesive product can be obtained after standing still after the vacuum is drawn.

[0033] Also in other embodiments, the optical adhesive formula provided by the present invention can also be mixed and cured to obtain an optical adhesive tape. Specifically, the embodiment of the present invention also provides a method for preparing an optical adhesive tape with a curved screen, which includes the following steps: stirring the raw materials of the above optical adhesive at a tempe...

Embodiment 1

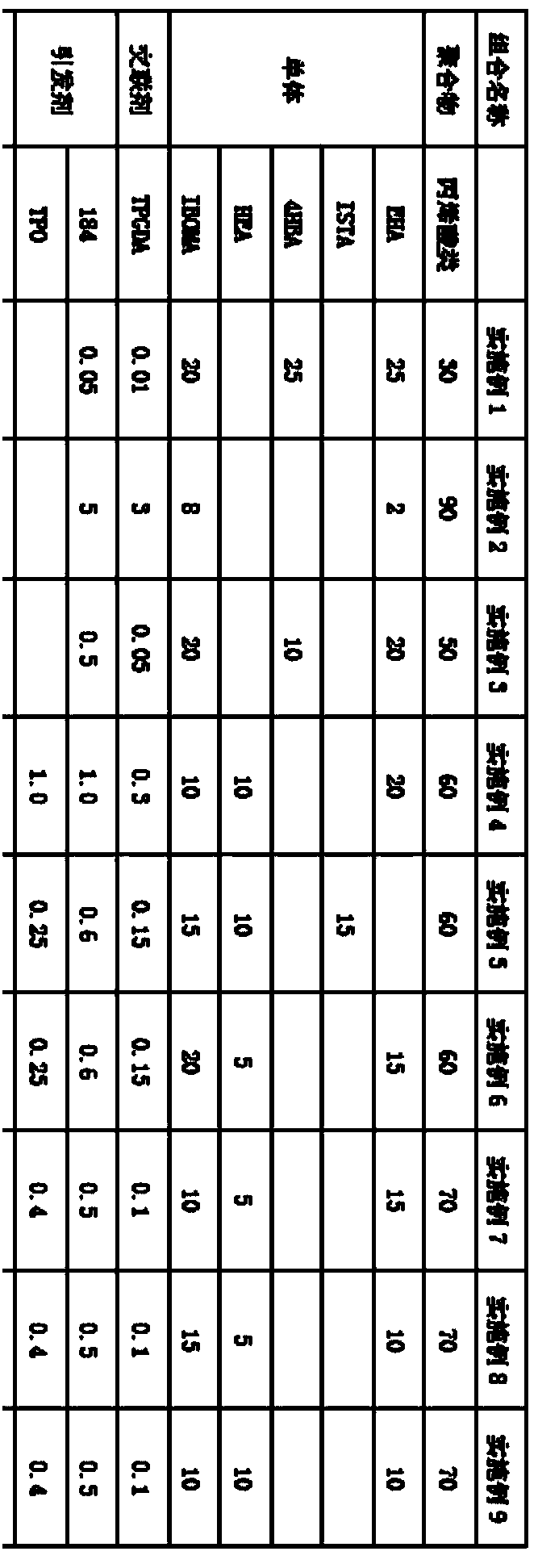

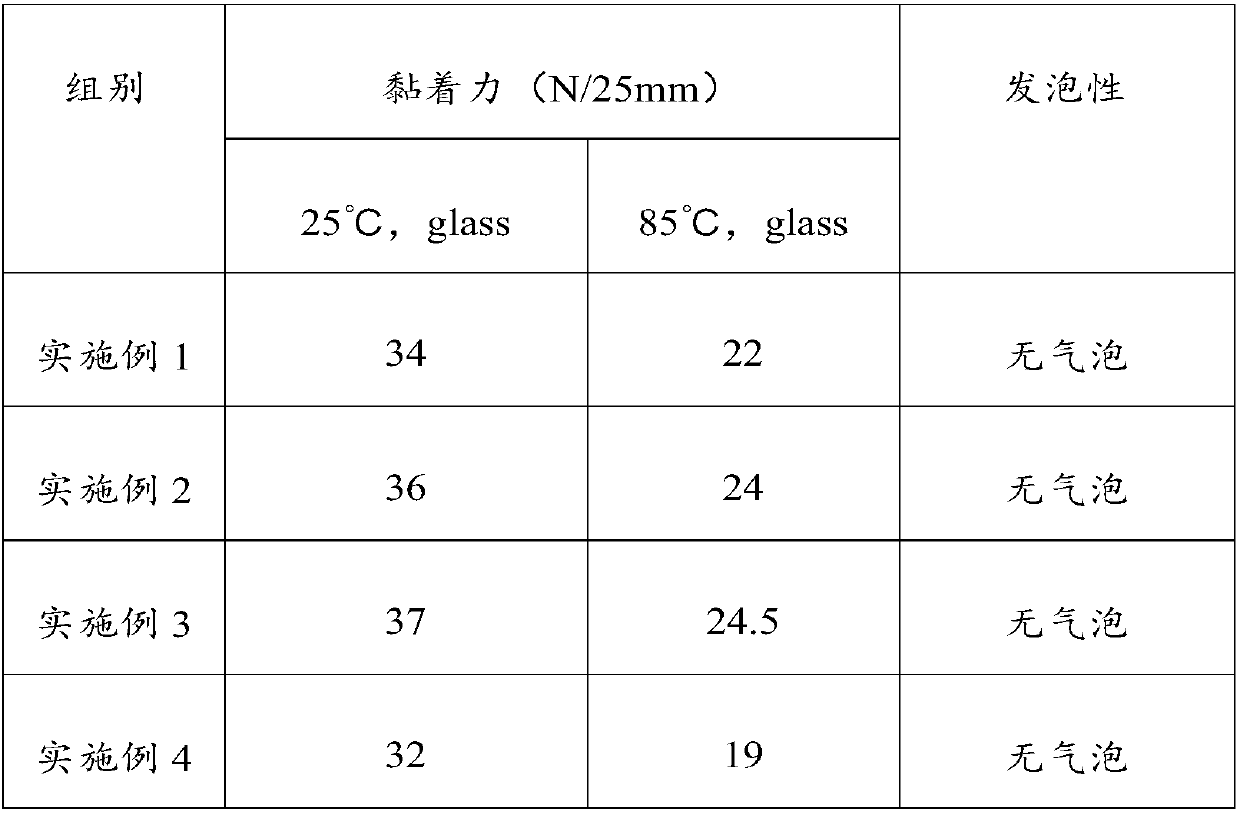

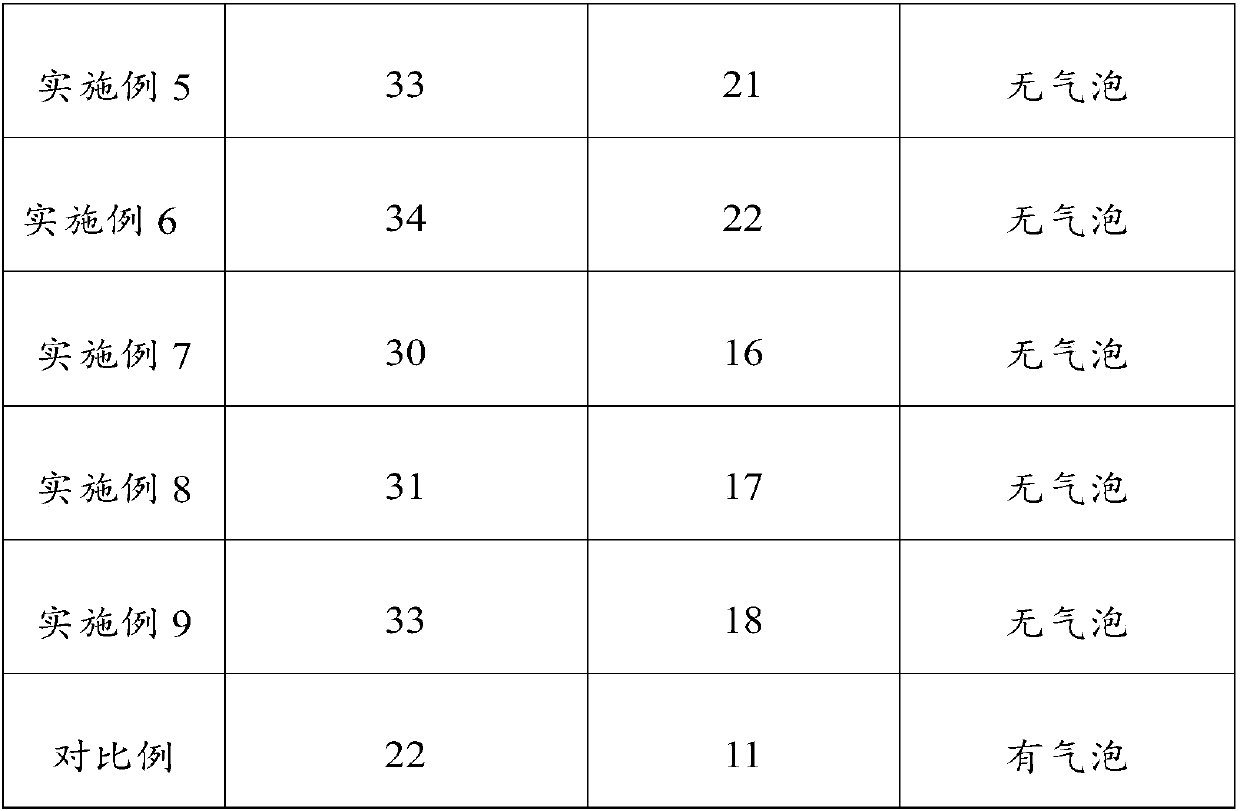

[0037] The formula of the optical adhesive in Examples 1-9 is as follows, such as the optical adhesive provided in Example 1, in parts by weight, including 30 parts of acrylic acid derivative polymer, 25 parts of isooctyl acrylate (EHA), 25 parts of acrylic acid 25 parts of hydroxybutyl ester (4HBA), 20 parts of isobornyl methacrylate (IBOMA), 0.05 parts of photoinitiator (0.05 parts of 1-hydroxycyclohexyl phenyl ketone 184 and 2,4,6-trimethylbenzene Formyl diphenylphosphine oxide TPO 0 part) 0.05 part and crosslinking agent (tripropylene glycol diacrylate TPGDA) 0.01 part.

[0038]

[0039] Other information about the optical adhesive formula in Examples 1-9 and the preparation method of the curved screen optical adhesive tape will be specifically introduced below.

[0040] Example 1

[0041] This embodiment provides an optical adhesive, wherein the molecular weight of the acrylic acid derivative polymer is about 20w.

[0042] This embodiment also provides a method for p...

Embodiment 2

[0045] This embodiment provides an optical adhesive, wherein the molecular weight of the acrylic acid derivative polymer is about 80w.

[0046] This embodiment also provides a method for preparing an optical adhesive tape with a curved screen, which includes the following steps:

[0047] Add the raw materials corresponding to Example 2 in the table into the stirred tank, heat to 50°C, and stir for 2 hours at a speed of 300r / min to obtain a uniform adhesive fluid; then, use a conventional method to coat the adhesive fluid After being clothed, it is cured and shaped under ultraviolet radiation with a wavelength of 320-420nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com