Polyester reflecting film and preparation method thereof

A technology of reflective film and polyester, applied in chemical instruments and methods, diffusing elements, instruments, etc., can solve the problem of increased thermal shrinkage of polyester reflective film, decreased mechanical properties of polyester reflective film, and large amount of dispersant added. and other problems, to achieve the effect of reducing thermal shrinkage, easy processing, and simplifying the formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

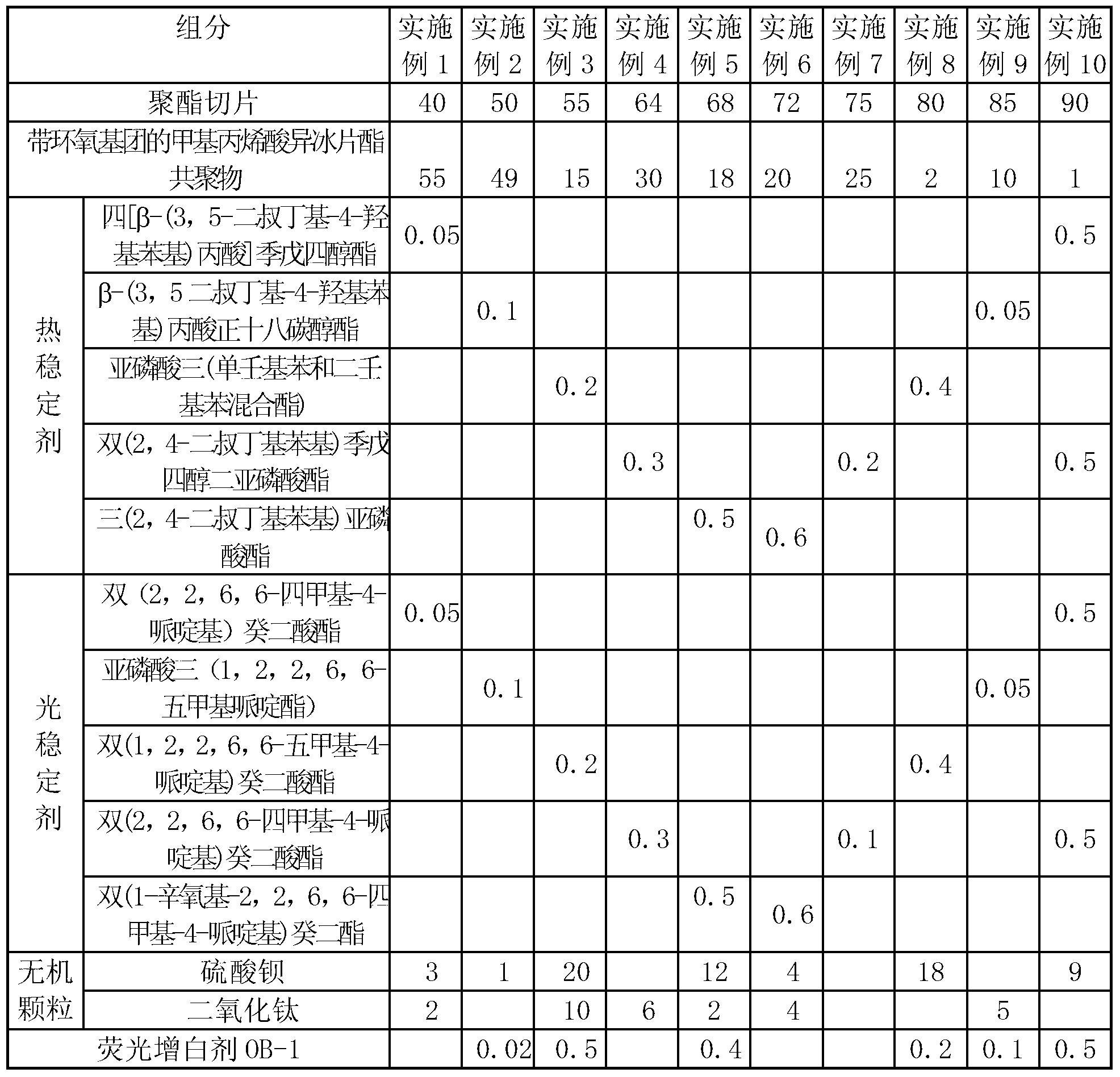

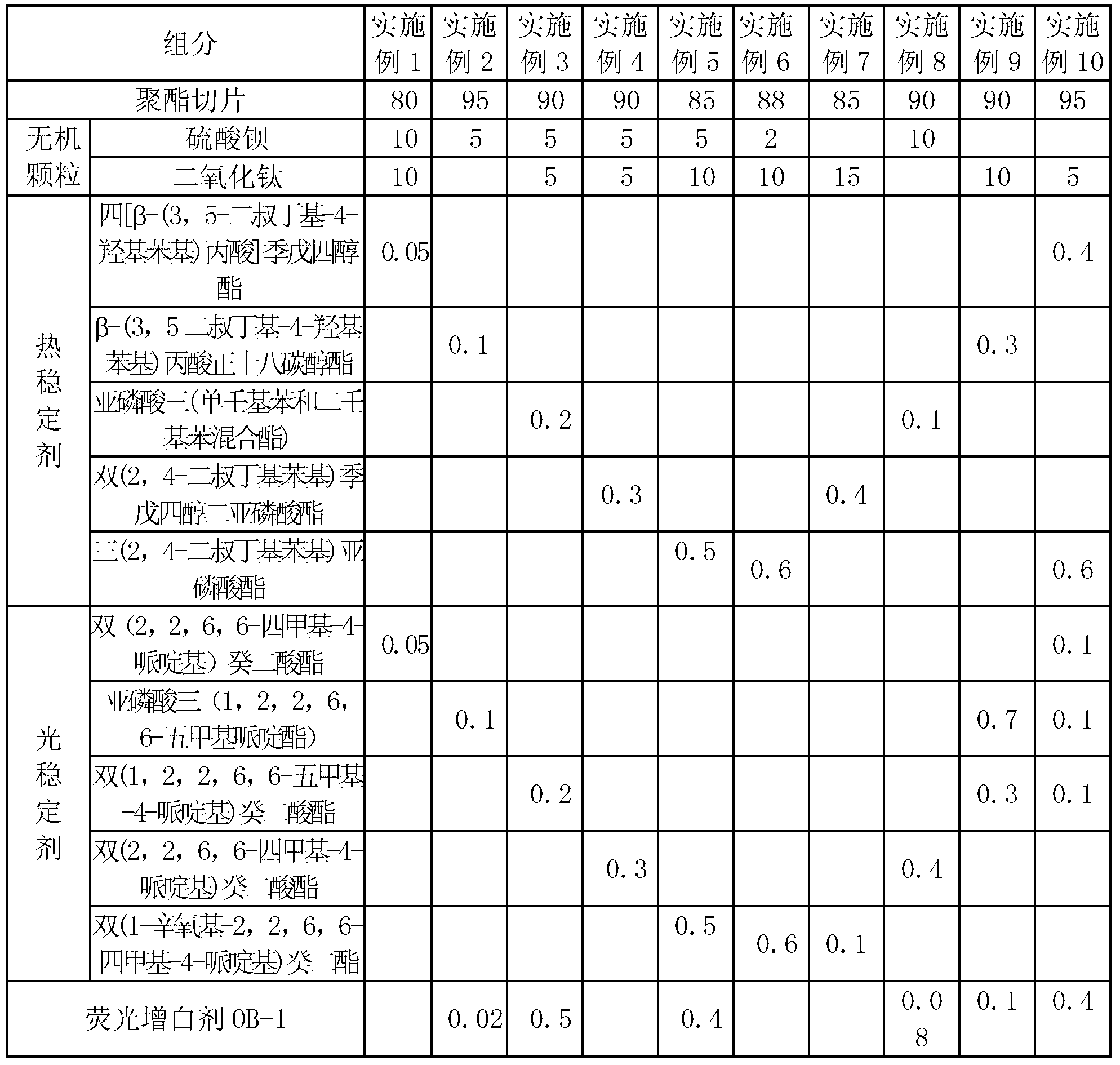

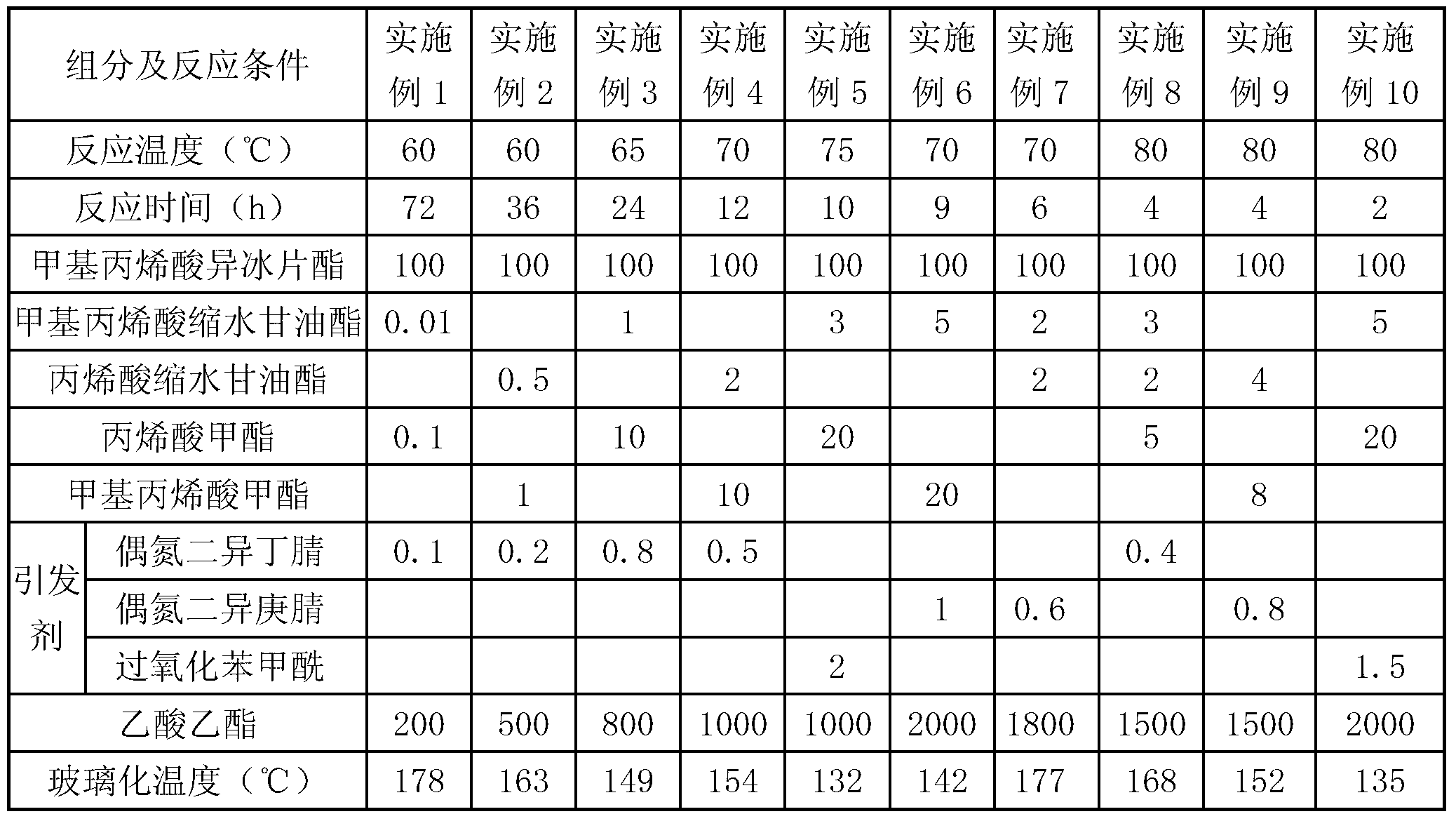

[0017] The polyester reflective film of the present invention includes more than one surface layer and a porous core layer in the middle, and can adopt a three-layer structure, that is, a core layer and a layer layer covering the upper and lower layers of the core layer; or a five-layer structure, that is, the core layer There are two layers above and below. The polyester reflective film component of the present invention is counted in parts by mass, and the core layer includes 40 to 90 parts of polyester chips, 1 to 55 parts of isobornyl methacrylate copolymer with epoxy groups, and 0.05 to 1 1 part of heat stabilizer and 0.05 to 1 part of light stabilizer. Preferably the core layer comprises 55-75 parts of polyester chips, 2-30 parts of isobornyl methacrylate copolymer with epoxy groups, 0.1-0.6 parts of heat stabilizer and 0.1-0.6 parts of light stabilizer agent. The core layer of the present invention can also have 1 to 30 parts of inorganic particles, such as 10 to 20 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com