OCA optical cement for mobile phone glass screen protector

A technology of screen protective film and glass protective film, applied in the field of OCA optical adhesive, can solve the problem of high price and achieve the effect of low price, excellent peeling force performance and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

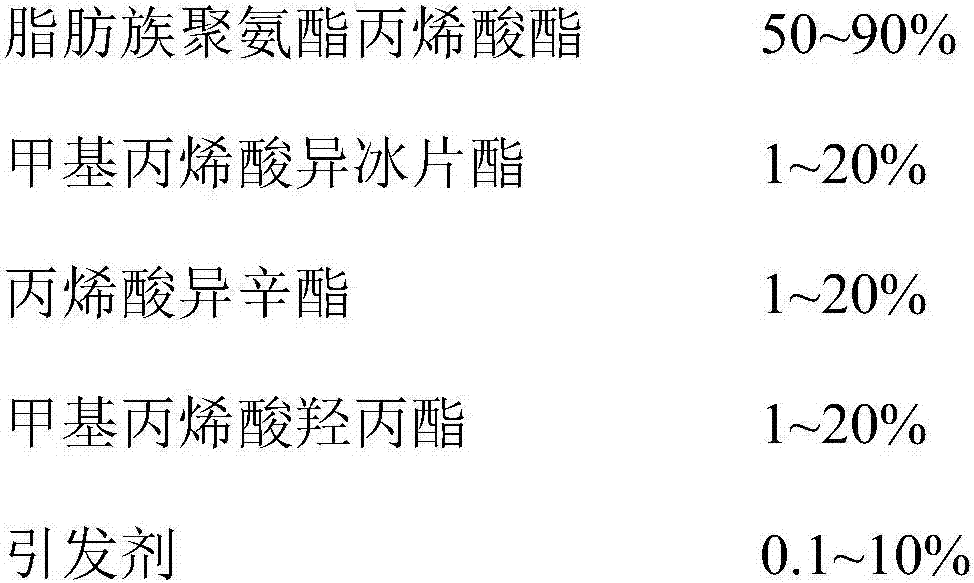

Embodiment 1

[0010]

[0011] Add the above components into the stirring tank according to the mass percentage, mix and stir evenly under the condition of avoiding light, then let it stand for defoaming naturally to make glue, then apply the glue on the PET release film, and use a scraper or a coating machine to coat it. Cloth, attached with a release PET film and cured by UV.

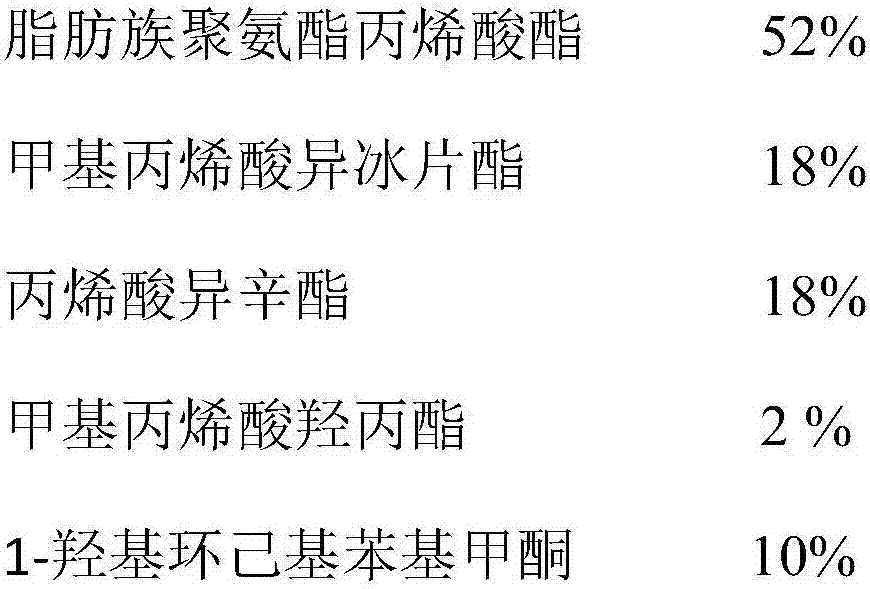

Embodiment 2

[0013]

[0014]

[0015] Add the above components into the stirring tank according to the mass percentage, mix and stir evenly under the condition of avoiding light, then let it stand for defoaming naturally to make glue, then apply the glue on the PET release film, and use a scraper or a coating machine to coat it. Cloth, attached with a release PET film and cured by UV.

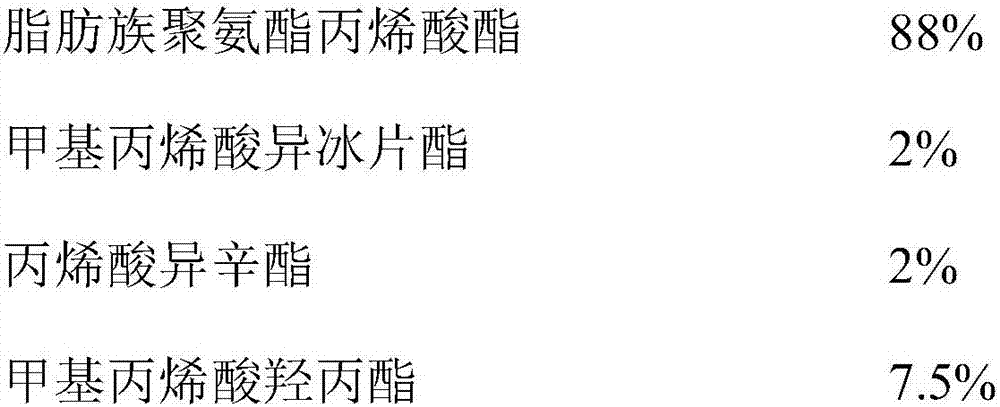

Embodiment 3

[0017]

[0018] Add the above components into the stirring tank according to the mass percentage, mix and stir evenly under the condition of avoiding light, then let it stand for defoaming naturally to make glue, then apply the glue on the PET release film, and use a scraper or a coating machine to coat it. Cloth, attached with a release PET film and cured by UV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com