Waste and old asphalt thermal circulation recycling regenerating agent and preparation method thereof

A waste asphalt, thermal cycle technology, used in building components, building insulation materials, construction and other directions, can solve the problems of lack of stability, human injury, high price, etc., to achieve excellent thermal stability and light stability, and volatilization of harmful substances. The effect of low dosage and improved safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

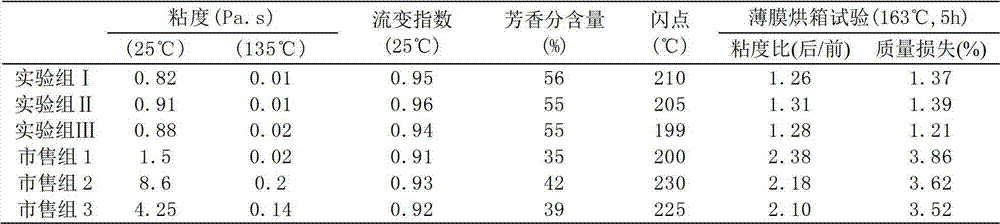

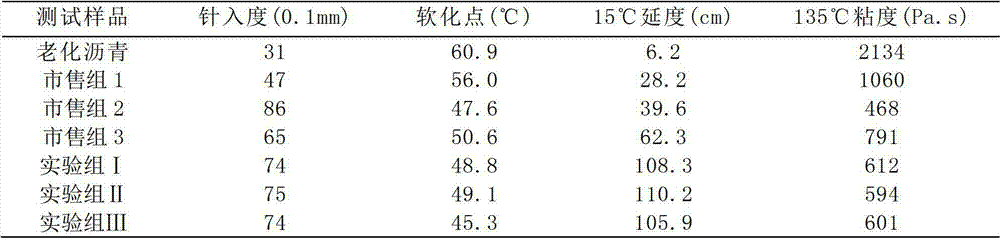

[0012] Weigh 75kg of oil extracted from the four-line extract, 12kg of epoxy soybean oil, 4kg of turpentine, 4kg of petroleum resin, ultraviolet absorber UV-5310.7kg, light stabilizer 6220.7 and antioxidant 10100.7kg, and heat the oil extracted from the four-line extract to 100 ~120°C, add epoxy soybean oil and turpentine and stir for 5 minutes; maintain the above temperature, add petroleum resin, ultraviolet absorber UV-531, light stabilizer 622, antioxidant 1010, stir for 5-10 minutes until the mixture is uniform, and prepare waste asphalt Thermal cycle regeneration using regenerant as experimental group Ⅰ;

[0013] Weigh 70kg of four-line extraction oil, 10kg of epoxidized soybean oil, 3kg of turpentine, 3kg of petroleum resin, ultraviolet absorber UV-5310.5kg, light stabilizer 6220.5 and antioxidant 10100.5kg and prepare waste and old asphalt according to the above method for thermal cycle recycling The regeneration agent was used as the experimental group II;

[0014] We...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com