Method for preparing colorless terpene resin

A technology of terpene resin and resin, applied in the field of preparation of colorless terpene resin, can solve the problems of no mention of removal, no mention of color of terpene resin, easy discoloration of terpene resin, etc. Heat resistance and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

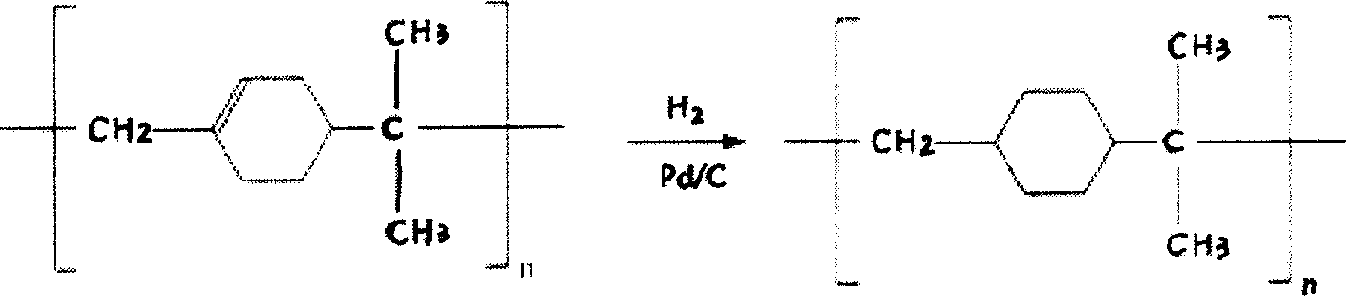

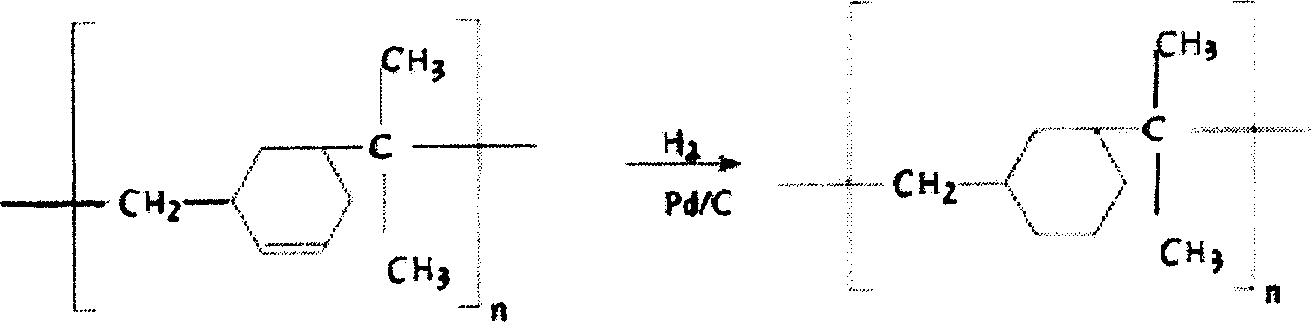

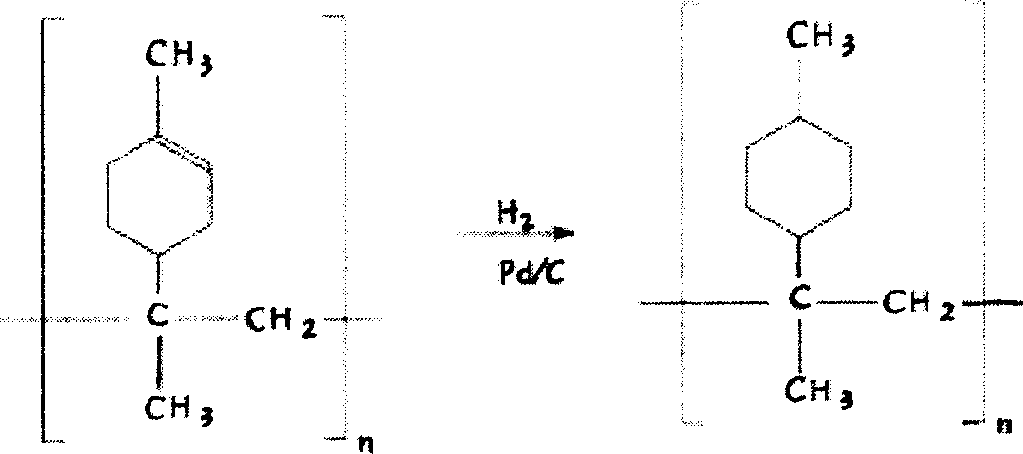

Method used

Image

Examples

Embodiment 1

[0035] 1) Preparation of terpene resin

[0036] By weight of the total amount of material, 5% of SbCl 3 Put it into a reaction kettle filled with 2L of toluene, cool down to -20°C, and then add 0.5 to 10% of anhydrous AlCl 3 Molecular sieve (anhydrous AlCl 3 Molecular sieve is anhydrous AlCl with a particle size of 10-30 mesh 3 Dissolve in absolute ethanol, then put 5A molecular sieve into it and soak for one day, then vacuum dry under nitrogen protection) or AlCl with a particle size of 20-30 mesh 3 Put it into the reaction kettle, stir, slowly add β-pinene dropwise, control the rate of addition, make the temperature rise in the reaction kettle at 2-10°C, keep warm for 1 hour after the pinene is added dropwise, warm up to room temperature, filter, and use the filtrate Stir with 0.5N dilute hydrochloric acid for 1 hour, let stand, and separate the oil layer, wash the oil layer with water for 3 to 4 times, and check that there is no Cl in the washing solution - Ions, Al 3-...

Embodiment 2

[0040] 1) Preparation of terpene resin

[0041] 10% SbCl 3 Put it into a reaction kettle filled with benzyl chloride, cool down to 0~-30℃, and then add 0.5~10% anhydrous AlCl 3 Molecular sieves or granules in 20-30 mesh AlCl 3 Put it into the reaction kettle, stir, slowly add α-pinene dropwise, control the rate of addition, make the temperature rise in the reaction kettle at 5-12°C, keep warm for 1 hour after the pinene is added dropwise, warm up to room temperature, filter, and use the filtrate Stir with 1N hydrochloric acid for 0.5 hours, let it stand, and separate the oil layer, wash the oil layer with water 3 to 4 times, and check that the washing liquid is free of Cl - Ions, Al 3+ Until the ions are removed, the washed reactant is vacuum distilled to obtain a terpene resin.

[0042] 2) Catalytic hydrogenation

[0043] Put 400g of the above-mentioned terpene resin and 0.5gPd / c (5.0% palladium content) into a 2L autoclave, add 400ml of n-hexane, and carry out catalytic...

Embodiment 3

[0045] 1) Preparation of terpene resin

[0046] By weight of the total amount of material, 2% of SbCl 3 Put it into a reaction kettle filled with 2L xylene, cool down to -20°C in a cold trap, and then add 0.5 to 10% of anhydrous AlCl 3 Molecular sieves or granules in 20-30 mesh AlCl 3 Put it into the reaction kettle, stir, slowly add dipentene dropwise, control the dropping speed, make the temperature rise in the reaction kettle at 2-8°C, keep warm for 1 hour after dipentene is added dropwise, raise the temperature to room temperature, filter, and use the filtrate Stir with 0.5N dilute hydrochloric acid for 1 hour, let stand, and separate the oil layer, wash the oil layer with water for 3 to 4 times, and check that there is no Cl in the washing solution - Ions, Al 3+ The washed reactants are vacuum distilled to obtain dipentene resin.

[0047] 2) Catalytic hydrogenation

[0048] Put 400g of dipentene resin and 0.2gPd / c (5.0% palladium content) into a 2L autoclave prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com