Slurry for silicon solar cell

A silicon solar cell and paste technology, applied in circuits, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc., can solve the problems of reducing the conversion efficiency of cells, reducing the melting temperature of aluminum powder, increasing costs, etc. Good economic benefits, improved electrical conductivity, improved contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

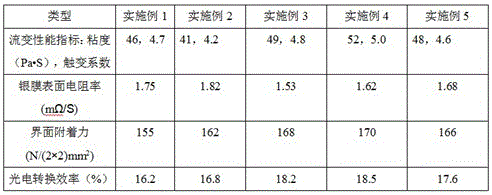

Examples

Embodiment 1

[0027] First prepare the lithium iron phosphate / carbon nanotube composite material:

[0028] (1) Ultrasonic disperse 8g of carbon nanotubes in a mixed solvent of 450g of ethanol and water with a volume ratio of 1:1 to form a carbon nanotube dispersion;

[0029] (2) Then add 20g of lithium carbonate, 10g of iron nitrate, 8g of lithium dihydrogen phosphate and 15g of sucrose to the carbon nanotube dispersion, heat and stir to form a slurry, cool to room temperature and ultrasonically disperse for 15min, then place in a vacuum drying oven for 15h , and then vacuumize and heat to 60°C until the solvent in the slurry evaporates completely;

[0030] (3) Pre-calcining the composite material treated in step (2) in a muffle furnace at 350° C. for 6 hours, and then firing at 750° C. for 6 hours to obtain the lithium iron phosphate / carbon nanotube composite material.

[0031] Then prepare glass powder and organic carrier, wherein the composition of glass powder I is 5~15 μm SiO 2 20g, ...

Embodiment 2

[0034] First prepare the lithium iron phosphate / carbon nanotube composite material:

[0035] (1) Ultrasonic disperse 5g of carbon nanotubes in a mixed solvent of 400g of ethanol and water with a volume ratio of 1:1 to form a carbon nanotube dispersion;

[0036] (2) Add 25g of lithium carbonate, 5g of iron nitrate, 5g of lithium dihydrogen phosphate and 10g of sucrose to the carbon nanotube dispersion, heat and stir to form a slurry, cool to room temperature and ultrasonically disperse for 10min, then place in a vacuum drying oven for 20h , and then vacuumize and heat to 50°C until the solvent in the slurry evaporates completely;

[0037] (3) Pre-calcining the composite material treated in step (2) in a muffle furnace at 300° C. for 7 hours, and then firing at 700° C. for 5 hours to obtain the lithium iron phosphate / carbon nanotube composite material.

[0038] Then prepare glass powder and organic carrier, wherein the composition of glass powder I is 5~15 μm SiO 2 15g, 5~15μmBi...

Embodiment 3

[0041] First prepare the lithium iron phosphate / carbon nanotube composite material:

[0042] (1) Ultrasonic disperse 10g of carbon nanotubes in a mixed solvent of 500g of ethanol and water with a volume ratio of 1:1 to form a carbon nanotube dispersion;

[0043] (2) Then add 20g of lithium carbonate, 10g of iron nitrate, 10g of lithium dihydrogen phosphate and 15g of sucrose to the carbon nanotube dispersion, heat and stir to form a slurry, cool to room temperature and ultrasonically disperse for 10min, then place in a vacuum drying oven for 20h , and then vacuumize and heat to 50°C until the solvent in the slurry evaporates completely;

[0044] (3) Pre-calcining the composite material treated in step (2) in a muffle furnace at 300° C. for 7 hours, and then firing at 700° C. for 5 hours to obtain the lithium iron phosphate / carbon nanotube composite material.

[0045] Then prepare glass powder and organic carrier, wherein the composition of glass powder I is 5~15 μm SiO 2 30g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com