Plant source compound formaldehyde clear spray, and preparation method and application thereof

A formaldehyde scavenger and plant-sourced technology, which is applied in the field of plant-sourced compound formaldehyde scavenger and its preparation, can solve the problems of environmental and human health impact, slow photocatalyst effect, and affect the formaldehyde removal performance of products, so as to achieve human and environmental friendliness , good formaldehyde removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the preparation of plant source composite formaldehyde scavenger

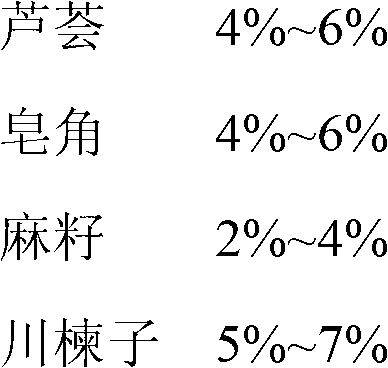

[0021] The raw material composition and weight percent of the plant source compound formaldehyde scavenger of the present embodiment are as follows:

[0022]

[0023]

[0024] The preparation method of the plant source compound formaldehyde scavenger of the present embodiment is specifically as follows:

[0025] Mix the above raw materials in proportion, soak for 150 minutes, then cook on low heat for 60 minutes, distill at 80°C, collect fractions, add water to dilute 5 times, stir for 15 minutes, add water to dilute 5 times, and ferment naturally for 20 minutes. Pack.

Embodiment 2

[0026] Embodiment 2, the preparation of plant source composite formaldehyde scavenger

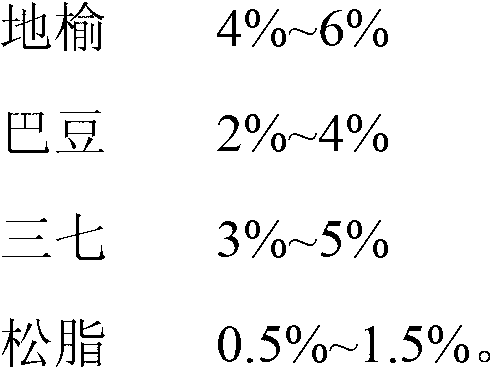

[0027] The raw material composition and weight percent of the plant source compound formaldehyde scavenger of the present embodiment are as follows:

[0028]

[0029] The preparation method of the plant source compound formaldehyde scavenger of the present embodiment is specifically as follows:

[0030] Mix the above raw materials in proportion, soak for 150 minutes, then cook on low heat for 60 minutes, distill at 80°C, collect fractions, add water to dilute 5 times, stir for 15 minutes, add water to dilute 5 times, and ferment naturally for 20 minutes. Pack.

Embodiment 3

[0031] Embodiment 3, the preparation of plant source composite formaldehyde scavenger

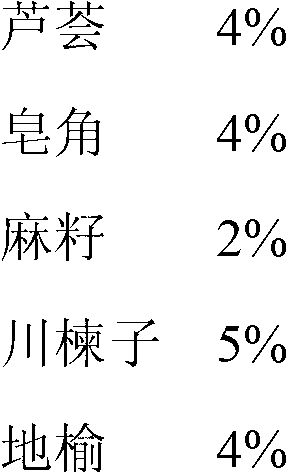

[0032] The raw material composition and weight percent of the plant source compound formaldehyde scavenger of the present embodiment are as follows:

[0033]

[0034]

[0035] The preparation method of the plant source compound formaldehyde scavenger of the present embodiment is specifically as follows:

[0036] Mix the above raw materials in proportion, soak for 150 minutes, then cook on low heat for 60 minutes, distill at 80°C, collect fractions, add water to dilute 5 times, stir for 15 minutes, add water to dilute 5 times, and ferment naturally for 20 minutes. Pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com