Amine catalyst for polyurethane foam and preparation method of amine catalyst

A technology of polyurethane foam and amine catalyst, applied in the chemical industry, can solve the problems of high harm to human body, high cost, single function, etc., and achieve the effects of good effect, high tensile strength and breaking strength, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method for the amine catalyst of polyurethane foam, wherein, described preparation method comprises the steps:

[0030] 1) The raw materials are weighed in parts by mass for subsequent use;

[0031] 2) Mix and stir or grind the weighed raw materials and mix them uniformly to obtain the amine catalyst.

Embodiment 1

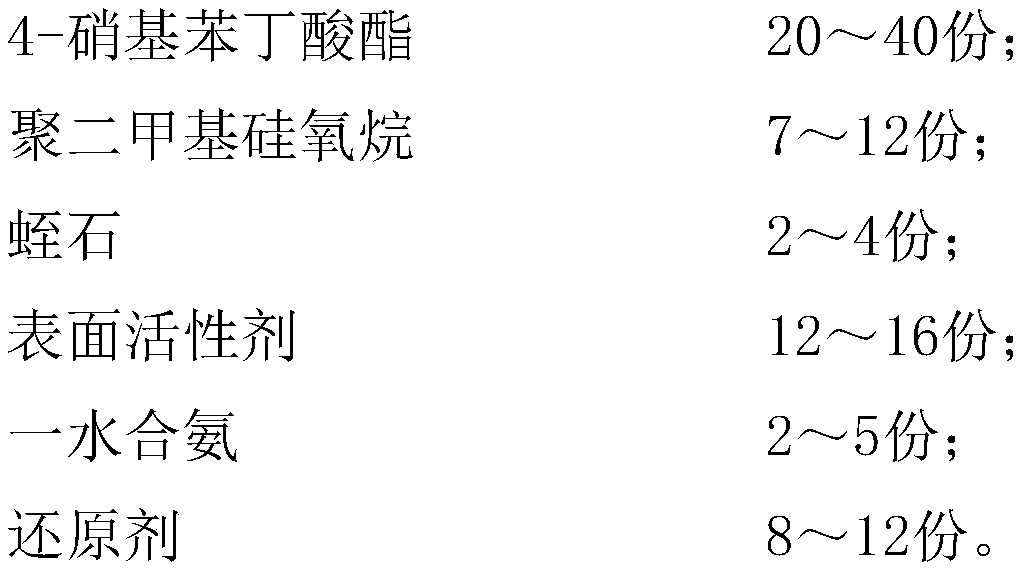

[0034] An amine catalyst for polyurethane foam, comprising the following raw materials in percentage by weight: 30% of dipropylene glycol, 32% of ZF10 catalyst, 20% of aldehyde remover, and 18% of auxiliary agent; in parts by weight, the aldehyde remover includes the following parts by weight s material:

[0035]

[0036]

[0037] The surfactant is fatty acid methyl ester polyoxyethylene ether; the reducing agent is stannous chloride; the auxiliary agent includes 32wt% ε-polylysine, 54wt% sodium gluconate and 14wt% trifluoropropyltrimethoxysilane.

[0038] A kind of preparation method for the amine catalyst of polyurethane foam, preparation method comprises the following steps:

[0039] 1) Dipropylene glycol, ZF10 catalyst, 4-nitrophenylbutyrate, polydimethylsiloxane, vermiculite, fatty acid methyl ester polyoxyethylene ether, ammonia monohydrate, stannous chloride, polyethylene wax, ε-polylysine, sodium gluconate and trifluoropropyltrimethoxysilane are weighed in parts...

Embodiment 2

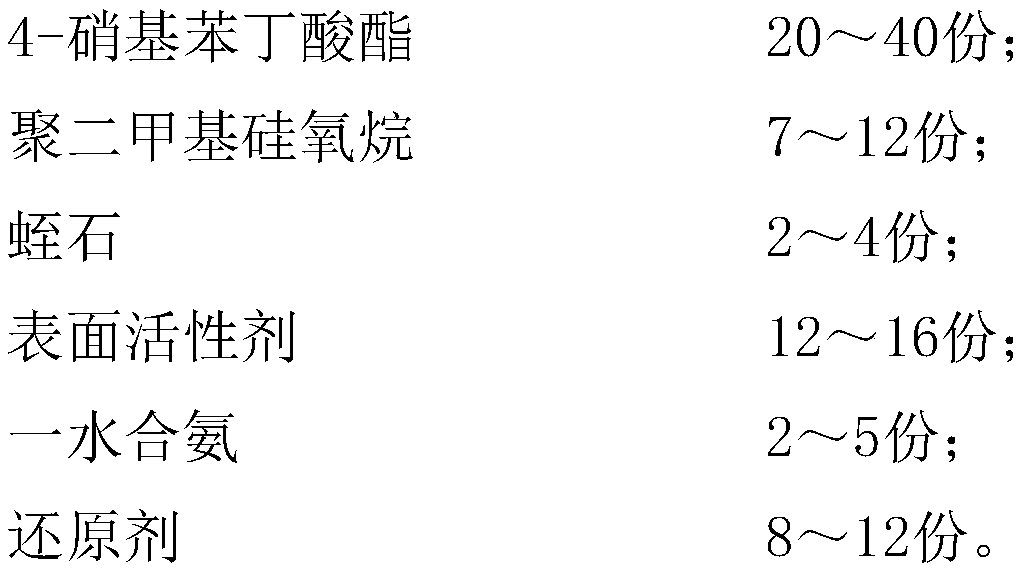

[0042] An amine catalyst for polyurethane foam, comprising the following raw materials in percentage by weight: 35% of dipropylene glycol, 30% of ZF10 catalyst, 18% of aldehyde remover, and 17% of auxiliary agent; in parts by weight, the aldehyde remover includes the following parts by weight s material:

[0043]

[0044] Surfactant is lignosulfonate and stearic acid monoglyceride, mass ratio is 1:2; Reducing agent is sodium borohydride; Auxiliary agent includes 34wt% ε-polylysine, 56wt% sodium gluconate and 10 wt% trifluoropropyltrimethoxysilane.

[0045] A kind of preparation method for the amine catalyst of polyurethane foam, preparation method comprises the following steps:

[0046] 1) Dipropylene glycol, ZF10 catalyst, 4-nitrophenylbutyrate, polydimethylsiloxane, vermiculite, lignosulfonate, monoglyceride stearate, ammonia monohydrate, sodium borohydride, Polyethylene wax, ε-polylysine, sodium gluconate and trifluoropropyltrimethoxysilane are weighed in parts by mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com