Normal-temperature non-viscous sealing adhesive for lithium battery and preparation method for sealing adhesive

A sealing adhesive, non-stick technology, applied in the direction of adhesive, adhesive type, adhesive additive, etc., to achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

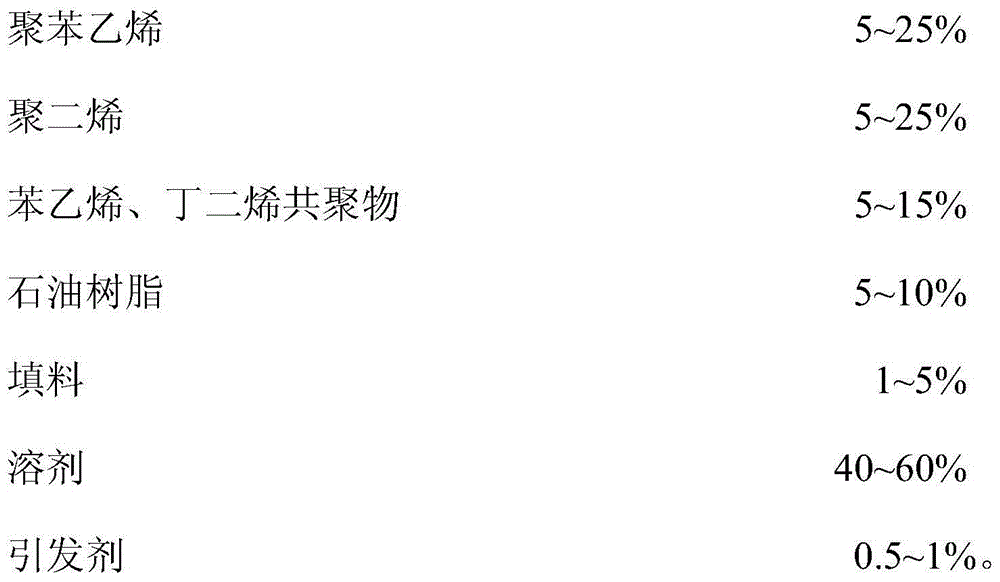

[0031] A normal temperature non-tack sealing adhesive for lithium batteries of the present invention comprises the following raw materials in mass percentage:

[0032]

[0033] A preparation method of a normal temperature non-tack sealing adhesive for lithium batteries, comprising the following processing steps:

[0034] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0035] Step B, adding all the SBS, all hydrogenated petroleum resins, toluene with 40% of the total amount of toluene and benzoyl peroxide with 40% of the total amount of benzoyl peroxide are added in the first reaction kettle, and the temperature is raised to 100° C., and kept 100°C constant temperature reaction for 30 minutes;

[0036] Step C, add all the polybutadiene, the remaining benzoyl peroxide and the remaining toluene into the second reaction kettle, mix evenly to form a mixed solution, slowly add the mixed solution into the first ...

Embodiment 2

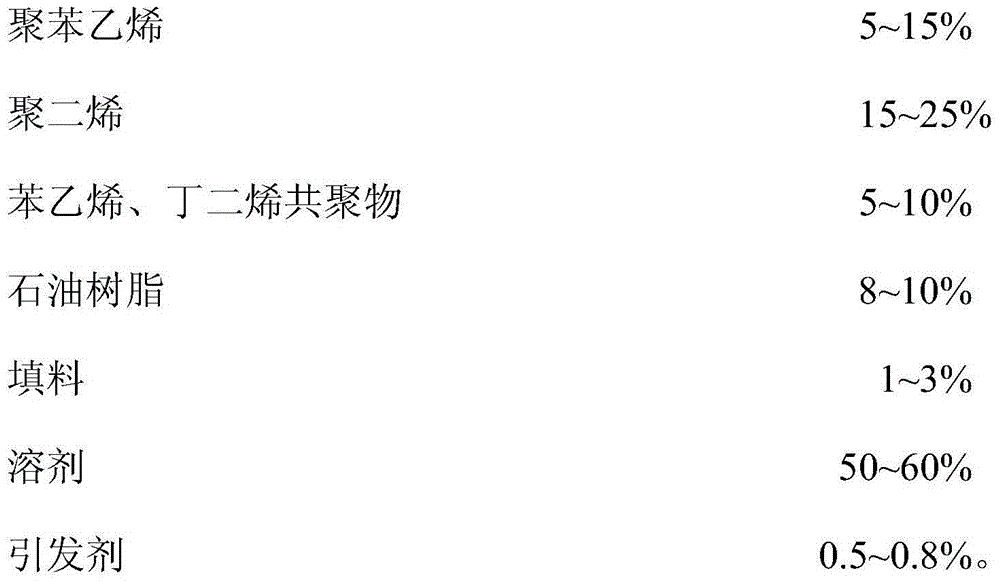

[0039] A normal temperature non-tack sealing adhesive for lithium batteries of the present invention comprises the following raw materials in mass percentage:

[0040]

[0041] A preparation method of a normal temperature non-tack sealing adhesive for lithium batteries, comprising the following processing steps:

[0042] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0043] Step B, adding all the SBS, all the hydrogenated petroleum resin, 50% of the total amount of xylene and 50% of the total amount of N,N-diethylaniline to the first reaction kettle During the process, the temperature was raised to 95°C, and the temperature was maintained at 95°C for 40 minutes;

[0044] Step C, add all the polypropylenediene, the remaining N,N-diethylaniline and the remaining xylene into the second reaction kettle, mix evenly to form a mixed solution, and slowly drop the mixed solution into the first reaction kettle , ...

Embodiment 3

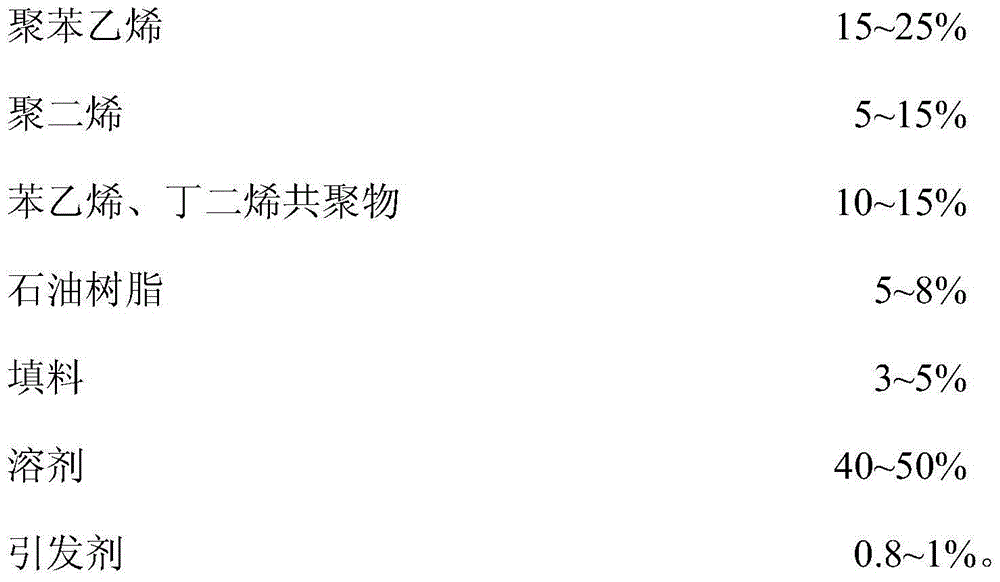

[0047] A normal temperature non-tack sealing adhesive for lithium batteries of the present invention comprises the following raw materials in mass percentage:

[0048]

[0049] A preparation method of a normal temperature non-tack sealing adhesive for lithium batteries, comprising the following processing steps:

[0050] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0051] Step B, adding all the SBS, all the hydrogenated petroleum resin, isopropanol with 30% of the total amount of isopropanol and azobisisobutyronitrile with 30% to 50% of the total amount of azobisisobutyronitrile into the first reaction kettle , raise the temperature to 105°C, and keep the constant temperature at 105°C for 20 minutes;

[0052] Step C. Add all the polypentadiene, the remaining azobisisobutyronitrile and the remaining isopropanol into the second reaction kettle, mix well to form a mixed solution, and slowly drop the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com