Refrigerating device and manufacturing method thereof

A technology for refrigeration devices and manufacturing methods, applied to household refrigeration devices, defrosting, household appliances, etc., which can solve the problems of poor anti-condensation effect, poor contact effect, and low heat conduction efficiency, and achieve high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In the first embodiment, a single-door refrigerator is taken as an example to introduce the refrigeration device of the present invention and its manufacturing method in detail.

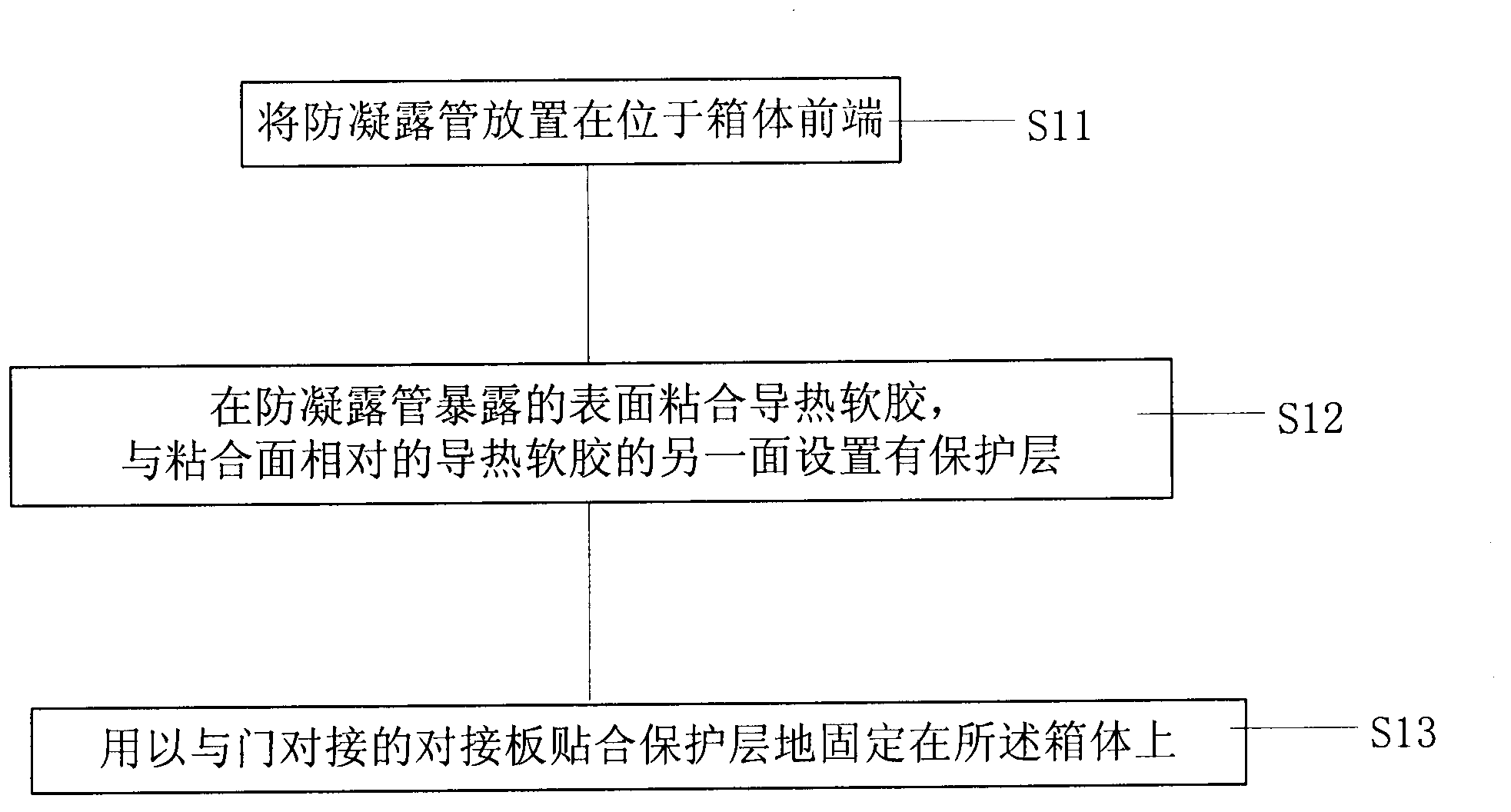

[0062] The following first introduces the production method, and its flow chart is shown in figure 1 shown.

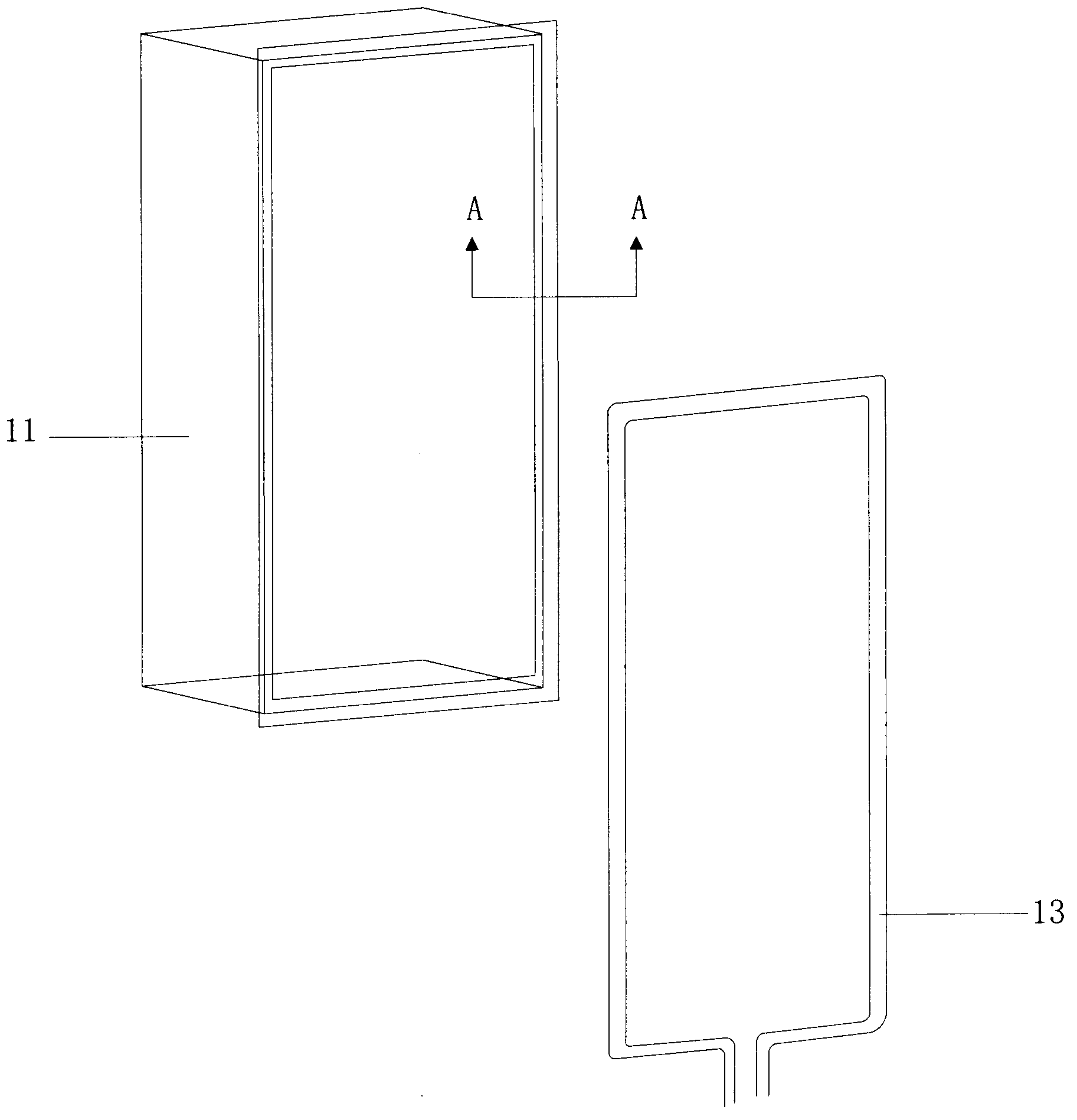

[0063] First, execute step S11, such as figure 2 As shown, the anti-condensation pipe 13 is placed at the front end of the box body 11 .

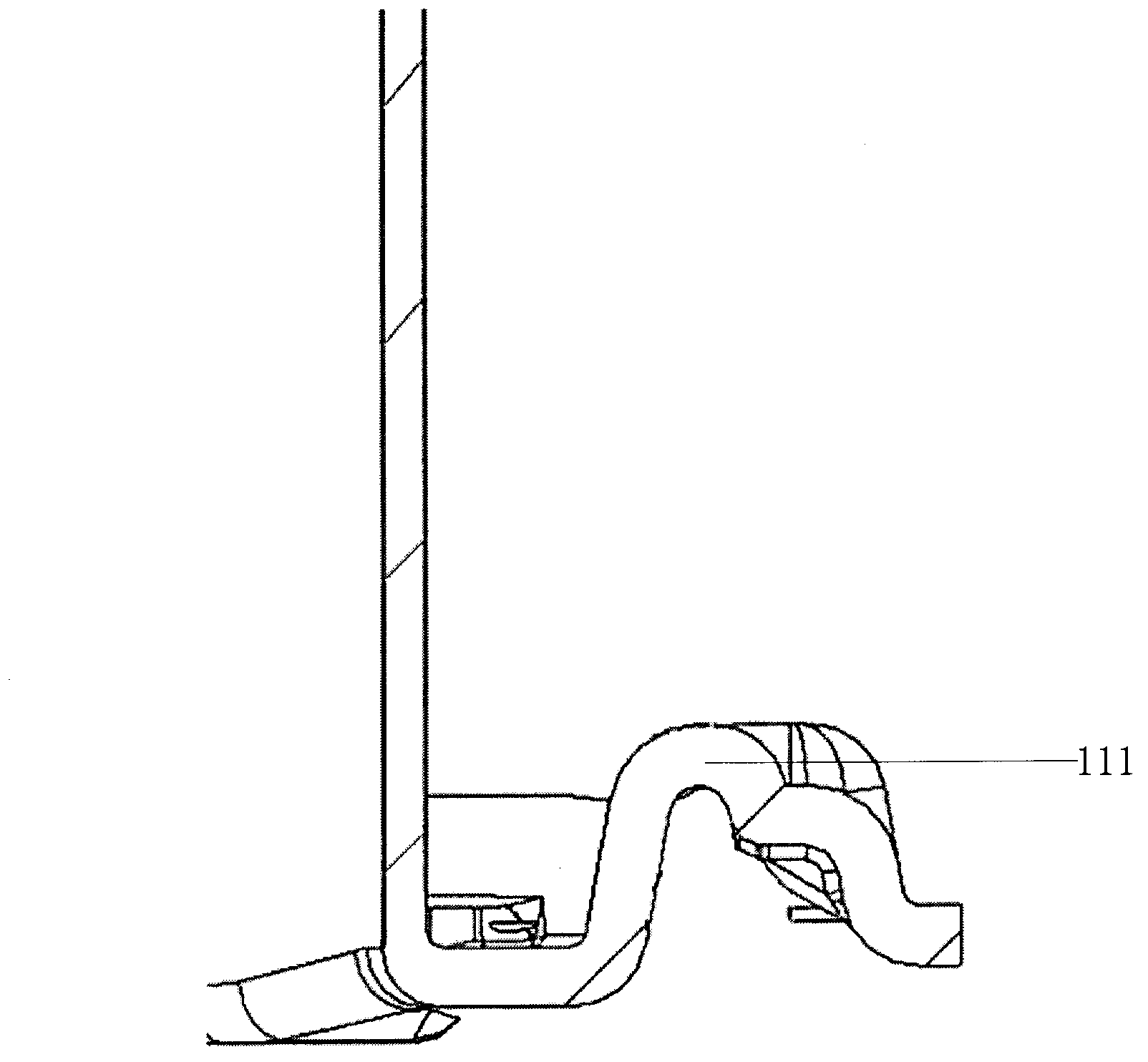

[0064]The above-mentioned front end of the box body 11 refers to the opening of the box body 11, and the opening is subsequently equipped with a door. In the first embodiment, the box body 11 of the single-door refrigerator is a freezer, and the opening of the freezer is the edge of the inner liner of the freezer. In other embodiments, the box body 11 of the single-door refrigerator can also be a cold room. In order to realize the fixing of the anti-condensation pipe 13, the casing 11 has a groove 111 near the edge of the door (the edge of the ...

Embodiment 2

[0089] The refrigerator provided in the second embodiment is roughly the same as the refrigerator in the first embodiment, the difference is that, as Figure 9 As shown, butt plate 12' has a U-shaped groove. When step S13 is executed, when the butt plate 12 is fixed on the box body 11 , one side of the U-shaped groove is attached to the protective layer 142 , and the other side is attached to the bottom of the groove 111 .

[0090] The arrangement of the above-mentioned U-shaped groove realizes the automatic engagement of the butt plate 12' on the box body 11, avoids the use of other fixing parts, reduces the cost, and improves the installation efficiency.

Embodiment 3

[0092] The refrigerator provided in this embodiment three is roughly the same as the refrigerator in embodiment one and the refrigerator in embodiment two, the difference is that, refer to Figure 10 The perspective view shown along with the Figure 10 Sectional view of line D-D in Figure 11 As shown, the refrigerator 3 is a refrigerator with two doors. At this time, the docking plate 12" is a middle partition separating the two doors. Condensation pipe 13.

[0093] It should be noted that, in order to visually display the positional relationship between the butt plate 12" (intermediate partition) and the box body 11 and the anti-condensation pipe 13, Figure 10 The butt plate 12" in the frame adopts a perspective effect.

[0094] It can be understood that, in other embodiments, the refrigerator can also have three or more doors, and two adjacent doors are separated by a middle partition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com