Heat exchanger core and heat exchanger equipped therewith

a technology of heat exchanger and core, which is applied in the direction of indirect heat exchanger, laminated elements, light and heating apparatus, etc., can solve the problems of insufficient heat exchanger strength, high production cost, and unused space produced between pipe portions, etc., and achieve the effect of producing with the required strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

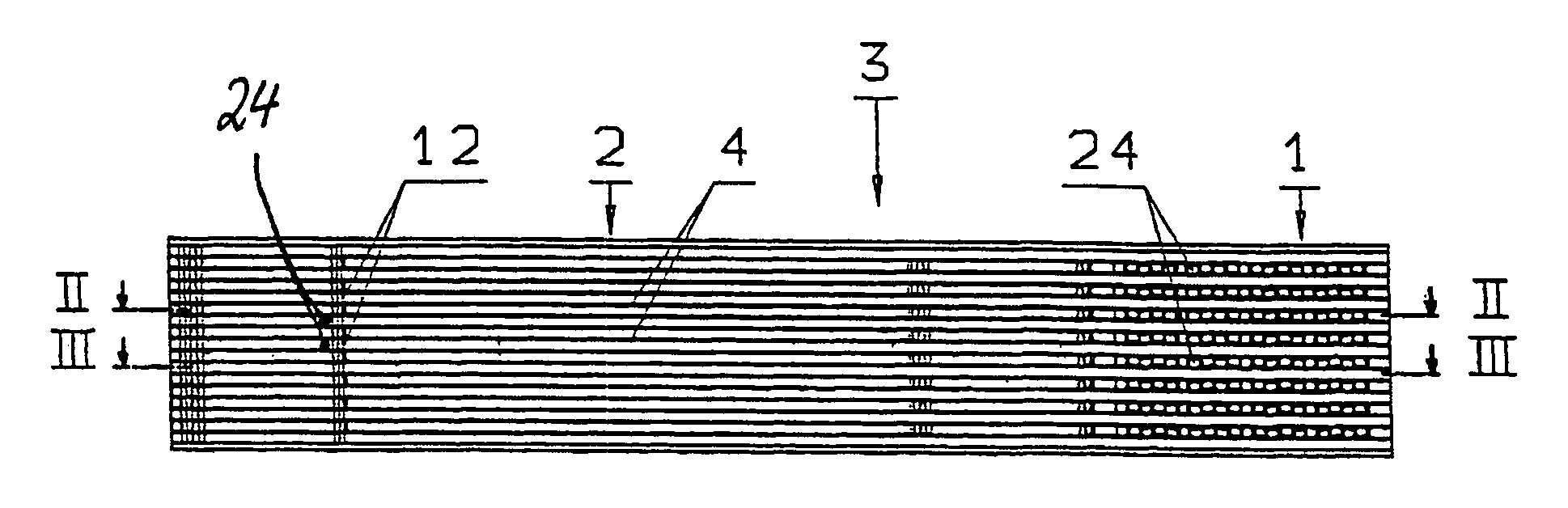

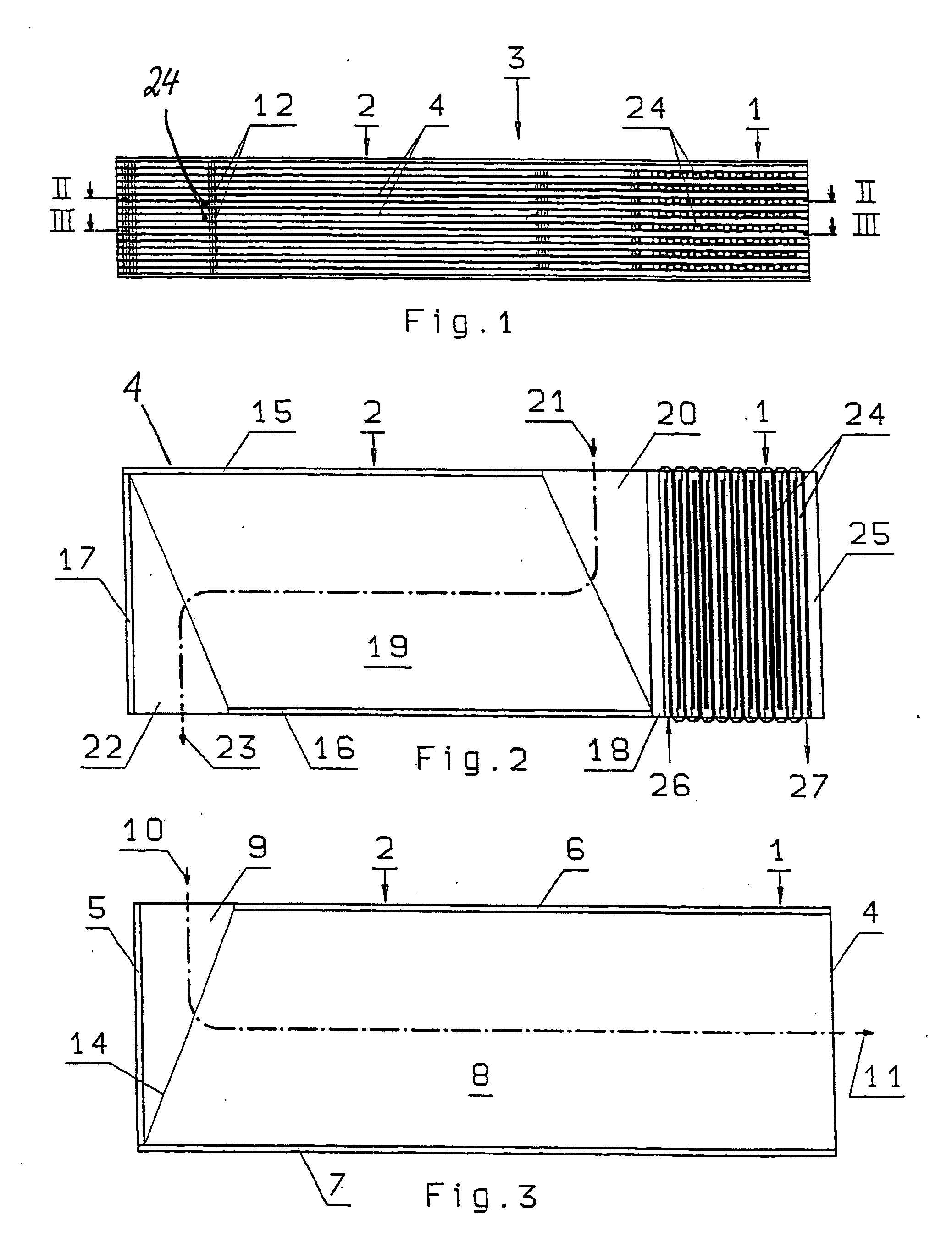

[0028] A heat exchanger device for cooling dryers in compressed air plants contains, according to FIG. 1 to 3, a coolant / air heat exchanger in the right portion and an air / air heat exchanger in the left portion. Only one coolant / air heat exchanger core 1 and, situated adjacently, one air / air heat exchanger core 2 are thereby illustrated, both being located beside each other in an assumed longitudinal direction, being combined into an integral constructional unit and forming a single, connected block 3. Of course, it would be possible also as an alternative to produce and to operate both cores 1 and 2 as separate constructional units.

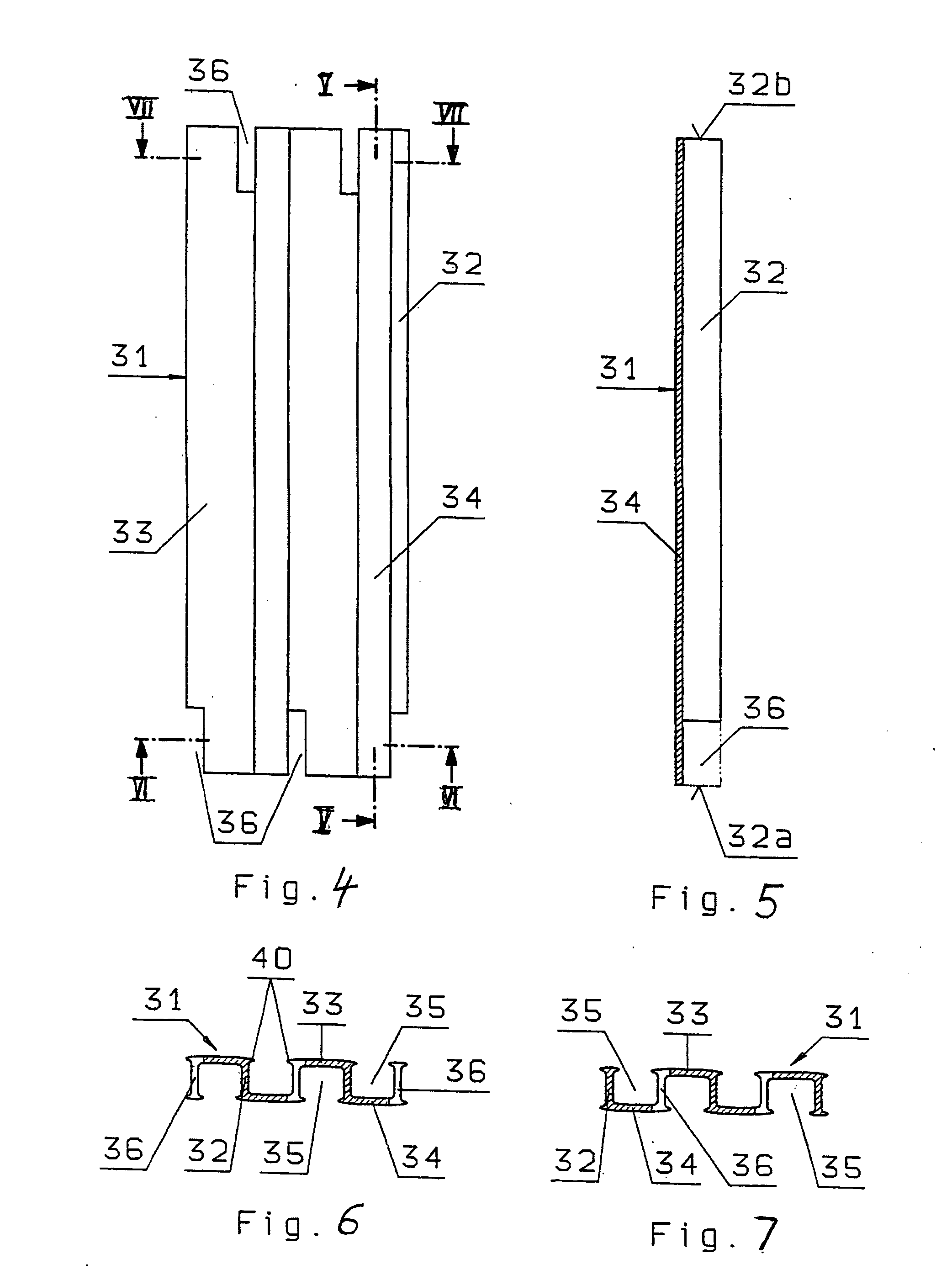

[0029] The two cores 1 and 2 are mainly formed by plane-parallel, rectangular or square plates or separating metal sheets 4, respectively, which extend over the entire width and length of the block 3. According to FIG. 1 and 3, a part of the plates 4 are spaced on the one hand by strips 5 which extend perpendicular to the longitudinal direction and are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com