Thin coating aluminum pigments, method for the production thereof, and use of said aluminum pigments

A technique of aluminium pigments, test methods, used in applications, pedicures, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

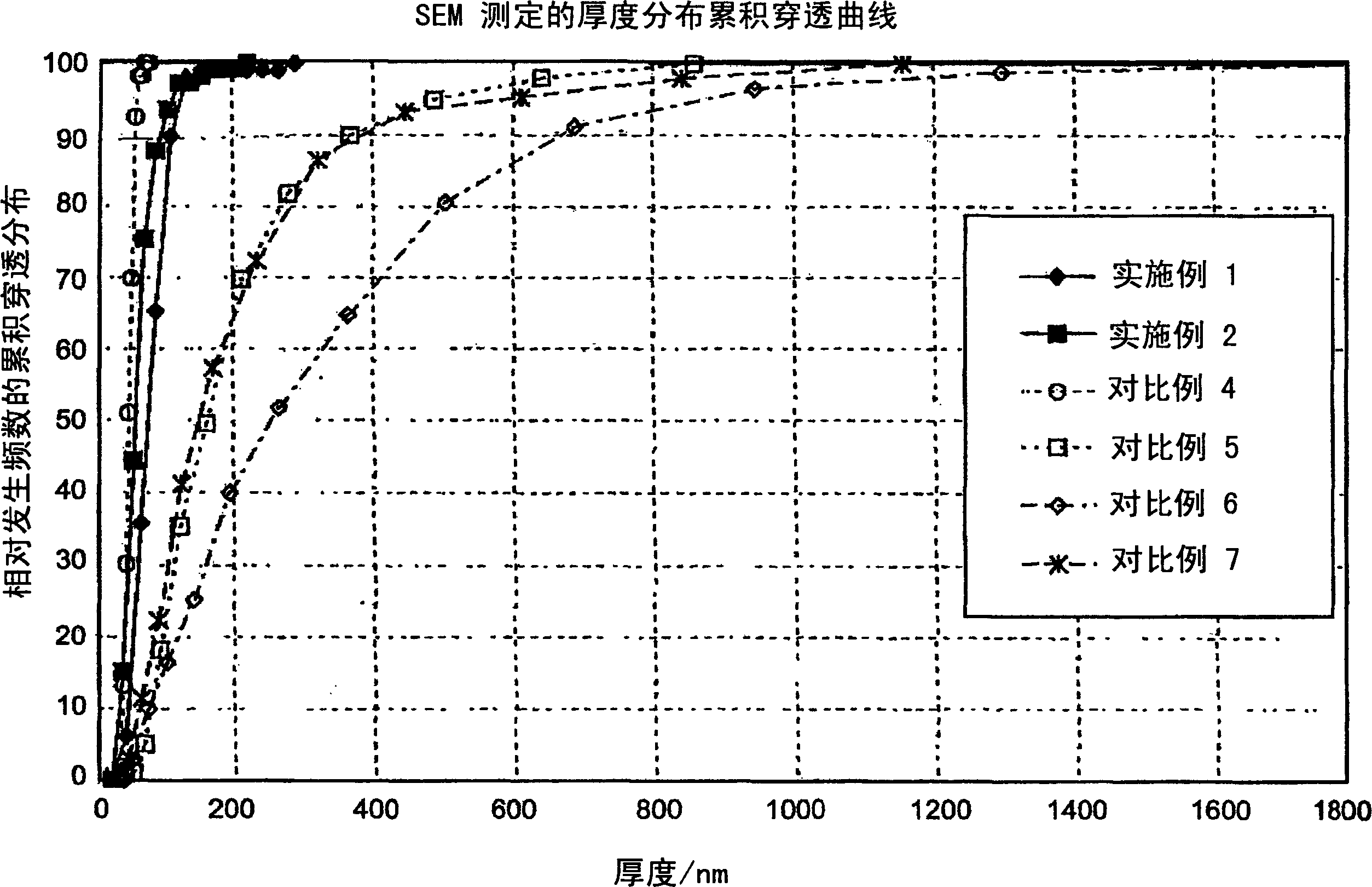

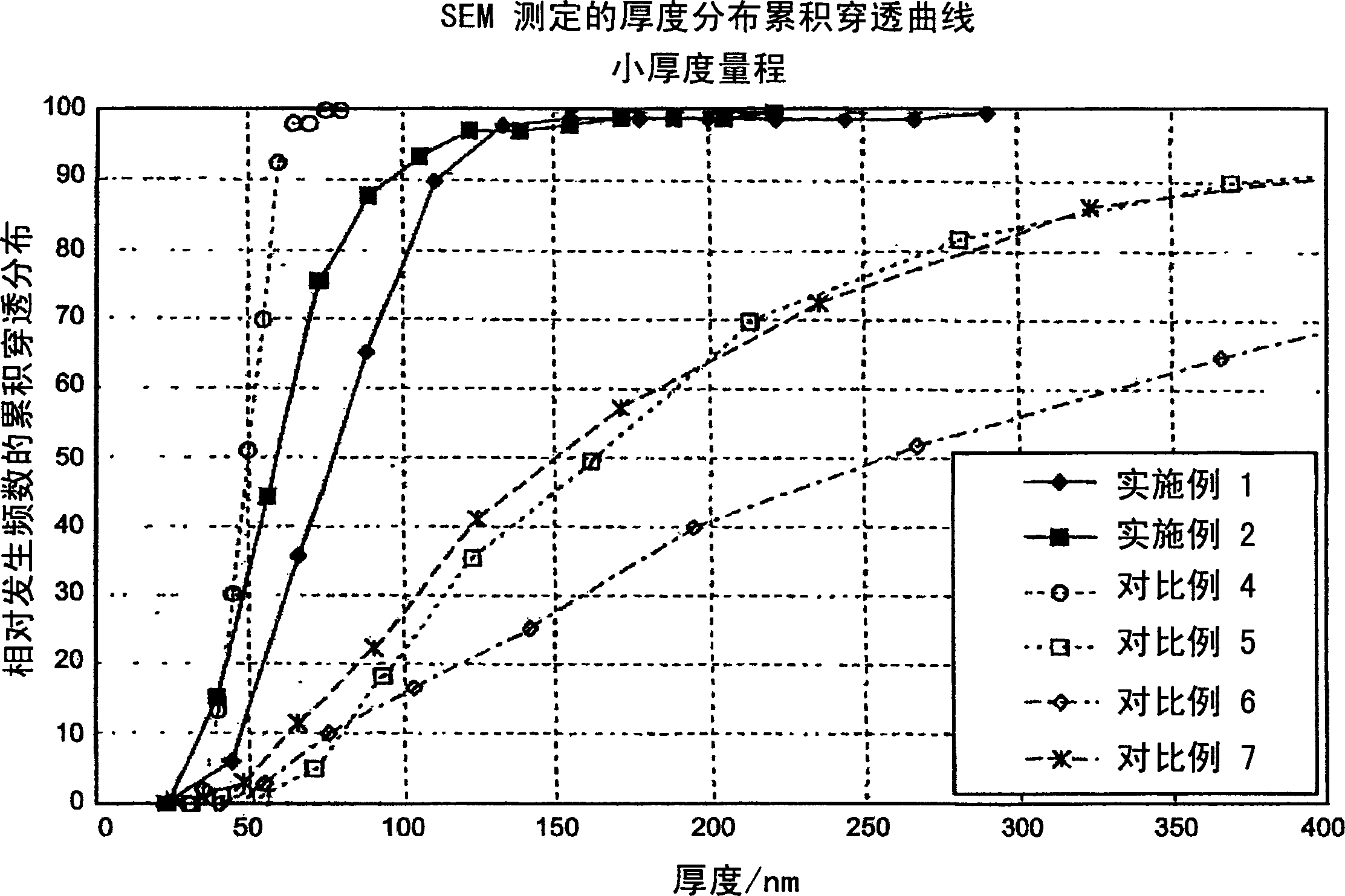

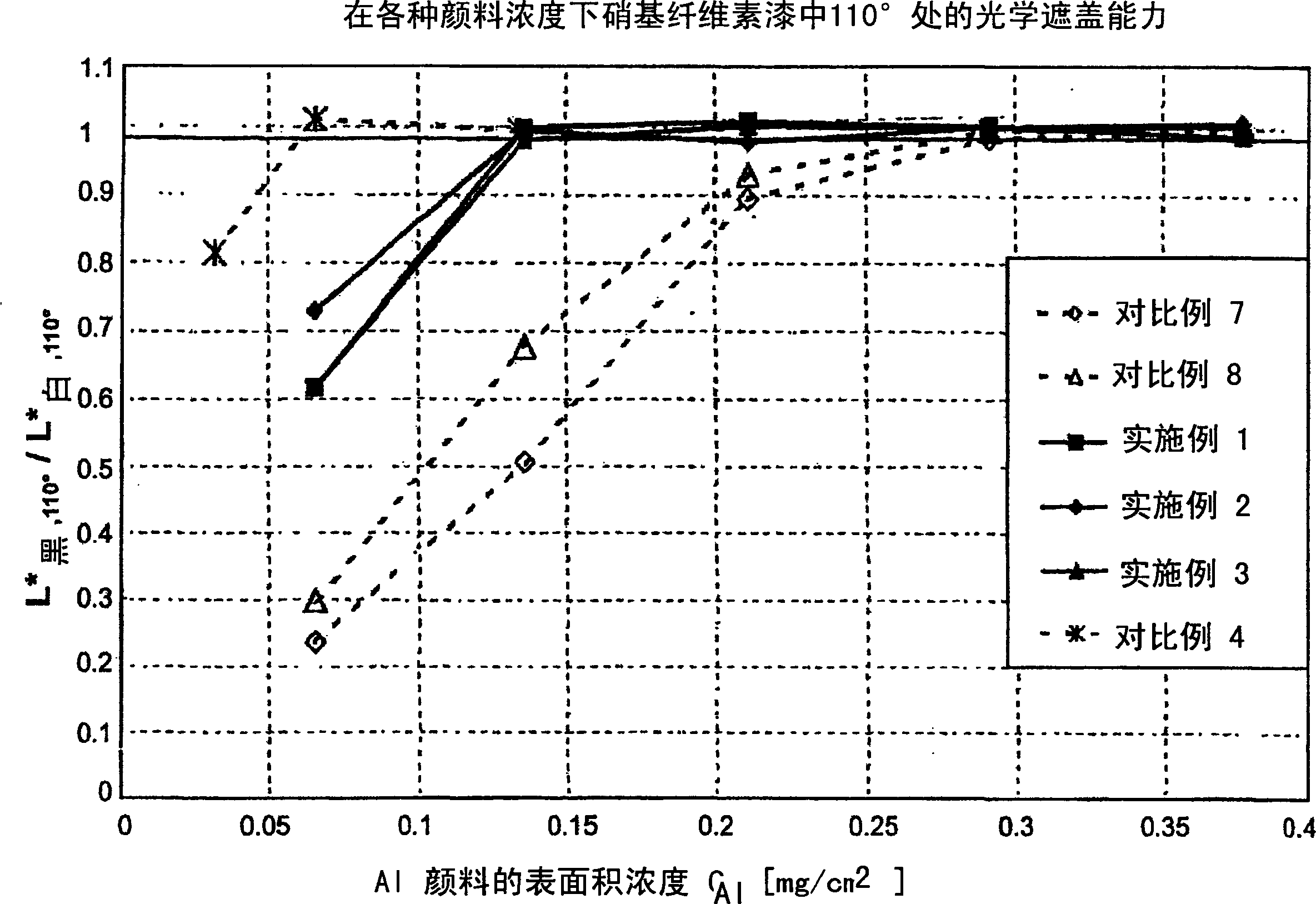

Image

Examples

Embodiment 1

[0133] 3.1 kg of glass spheres (diameter: 2 mm), 310 g of white spirit, 93 g of aluminum pellets (average diameter < 8 μm) and 9.3 g of oleic acid were placed in a drum mill (length: 32 cm, width: 19 cm). Next, the mixture was milled at 57 rpm for 20 hours. The product was separated from the milling balls by washing with white spirit, followed by a wet sieving process on a 25 μm sieve to sieve the product. The sieved fines were suction filtered to remove the petroleum solvent and then made into a paste (approximately 70% solids) with petroleum solvent in a laboratory blender.

Embodiment 2

[0135] Grinding was carried out as described in Example 1, but with aluminum pellets having an average diameter < 6 µm, and the grinding time was 23 hours.

Embodiment 3

[0137] 5.0kg of steel balls (diameter: 1.1mm, weight 5.5mg), 160g of petroleum solvent, 150g of aluminum pellets (average diameter < 8μm) and 6g of oleic acid were placed in a drum mill (length: 32cm, width: 19cm). Next, the mixture was milled at 60 rpm for 20 hours. During sieving, the product was separated from the milling balls by thorough washing with petroleum solvent, followed by wet sieving on a 25 μm sieve to sieve the product. The sieved fines were suction filtered to remove the petroleum solvent and then made into a paste (approximately 70% solids) with petroleum solvent in a laboratory blender.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com