Quick response and recovery type barium titanate nanofiber humidity dependent sensor

A moisture-sensitive sensor and nanofiber technology, which is applied in the direction of material impedance, can solve the problems that the response and recovery time have not been significantly improved, the moisture-sensitive characteristics of barium titanate blocks are not perfect, and the response and recovery time is long, etc. Grain boundaries, high sensitivity, and rapid recovery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

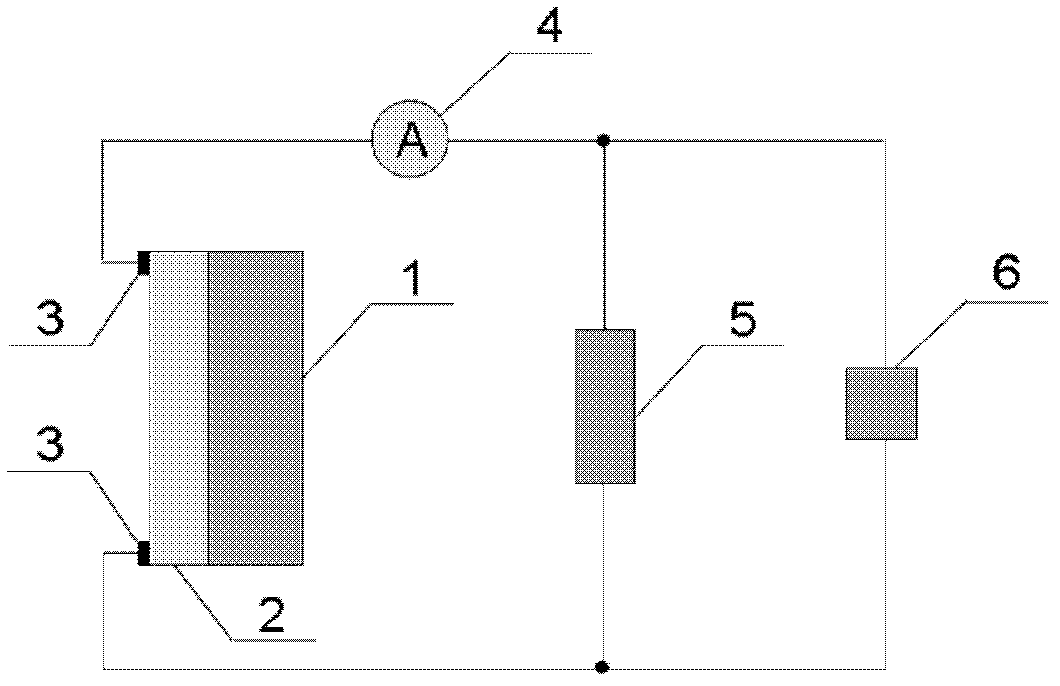

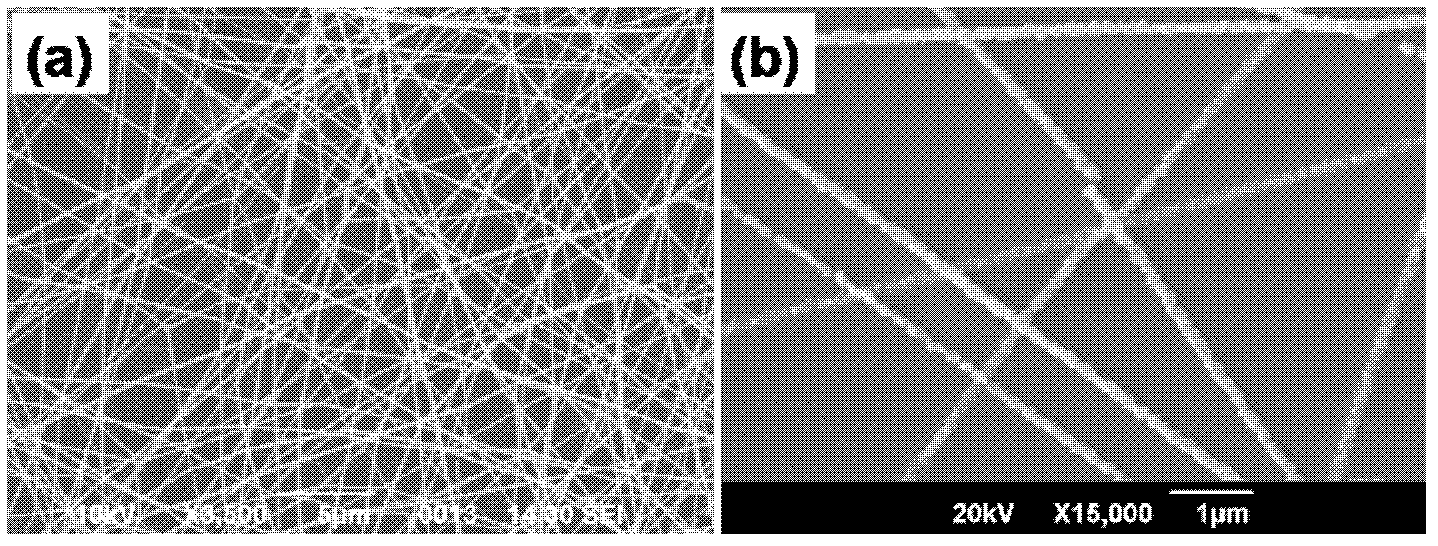

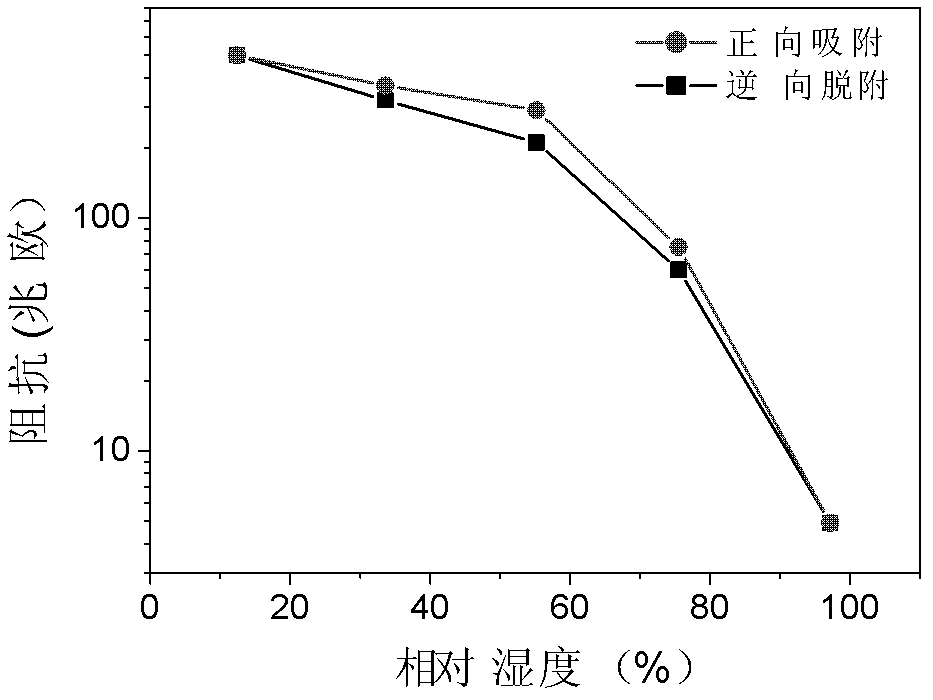

[0013] The main structure of the fast response and recovery type humidity sensor involved in this embodiment includes a substrate 1, a humidity response layer 2, an electrode 3, an ammeter 4, a rheostat 5 and a DC power supply 6; the non-conductive lining is made of glass, mica or sapphire The humidity response layer 2 formed by the collection method on the bottom substrate 1 is barium titanate nanofibers prepared by electrospinning, the thickness of which is 100 nm to 1 micron, and the non-woven structure barium titanate formed by electrospinning is collected The substrate 1 of the nanofiber humidity response layer 2 is packaged in a closed-cavity shell, and the electrode leads are drawn out through the electrode 3 with a coaxial cable; the electrode 3 is a point-shaped, linear or planar structure, connected by silver glue or soldered with indium , or use vacuum coating method to vapor-deposit platinum, gold, silver or aluminum electrodes; the varistor 5 with adjustable resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com