Three-dimensional porous nickel oxide and nitrogen doped graphene quantum dot composition as well as preparation method and application thereof

A graphene quantum dot, three-dimensional porous technology, applied in the direction of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of electrocatalyst structure, composition and electrocatalytic performance difficulties, and achieve superior electrocatalysis Catalytic performance, increasing specific surface area, improving the effect of oxygen evolution electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1. Preparation of nitrogen-doped graphene quantum dots

[0024] Synthesis of Nitrogen-Doped Graphene Quantum Dots by Modified Microwave Method [See: Lv J-J, Zhao J, Fang H, Jiang L-P, Li L-L, Ma J*, and Zhu J-J*, Incorporating Nitrogen-Doped GrapheneQuantum Dots and Ni 3 S 2 Nanosheets: A Synergistic Electrocatalyst with HighlyEnhanced Activity for Overall Water Splitting, Small, 2017, 13(24), 1700264], including the following steps:

[0025] (1) Take an appropriate amount of deseeded watermelon pulp, mash it into juice, put it into a 100mL polytetrafluoroethylene reactor, conduct hydrothermal treatment at 180°C for 12 hours, dialyze the obtained black carbon gel, and dry it in vacuum;

[0026] (2) Take 0.5 g of the prepared carbon gel and place it in a quartz boat after being ground, and heat up to 800 °C for 30 minutes in a tube furnace under a nitrogen atmosphere at a rate of 10 °C / min. Nitric acid and 30 mL of concentrated sulfuric acid were carefully ...

Embodiment 2

[0027]Embodiment 2. in-situ growth in the preparation of nickel oxide and nitrogen-doped graphene quantum dot composite on the surface of nickel foam, the specific steps are as follows:

[0028] (1) Ultrasonic cleaning of nickel foam (size: 0.5cm x 0.5cm) with ethanol and water for 30 minutes, and then drying it in a vacuum oven at 40°C for use;

[0029] (2) Take 5mL purified and quantified nitrogen-doped graphene quantum dot aqueous solution (0.5mg / mL) and 20mL oxidation etchant trioctylphosphine oxide aqueous solution (0.95mg / mL), mix well, transfer to 30mL polytetrafluoroethylene Vinyl fluoride reactor, add cleaned nickel foam (size: 0.5cm x 0.5cm), carry out hydrothermal treatment at 180°C for 12 hours, after cooling to room temperature, the product is rinsed several times with secondary water and ethanol and heated at 50 Drying in a vacuum drying oven at ℃ to obtain a composite of nickel oxide and nitrogen-doped graphene quantum dots grown on the surface of nickel foam in...

Embodiment 3

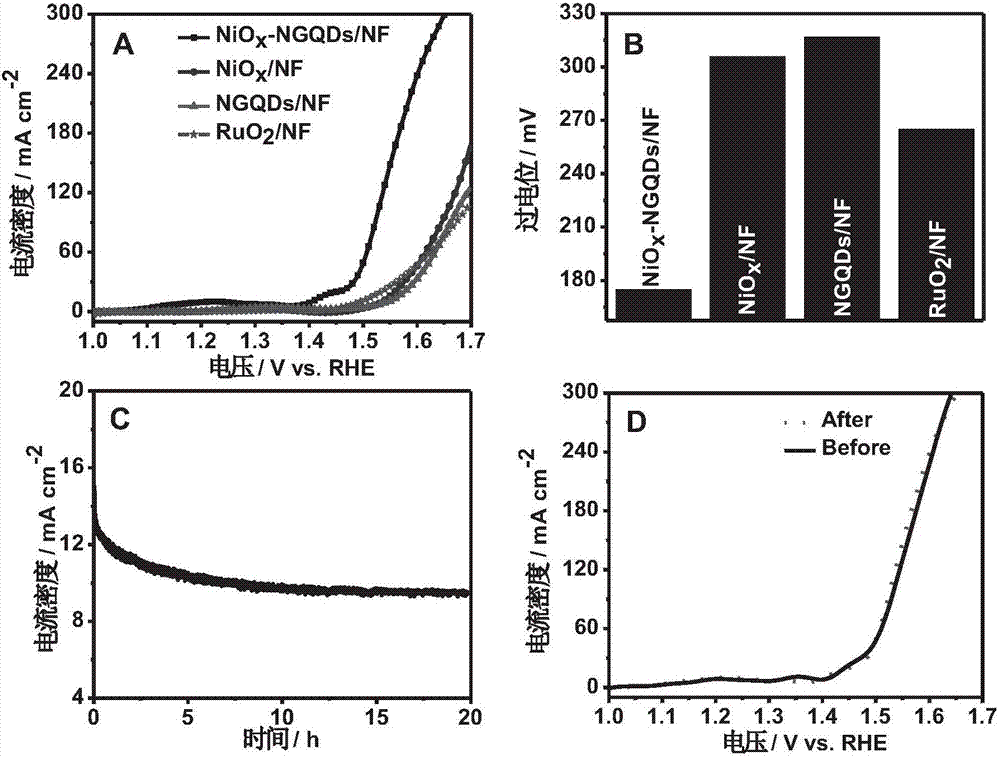

[0030] Embodiment 3. the characterization of in-situ growth on the nickel foam surface nickel oxide and nitrogen-doped graphene quantum dot composites, including:

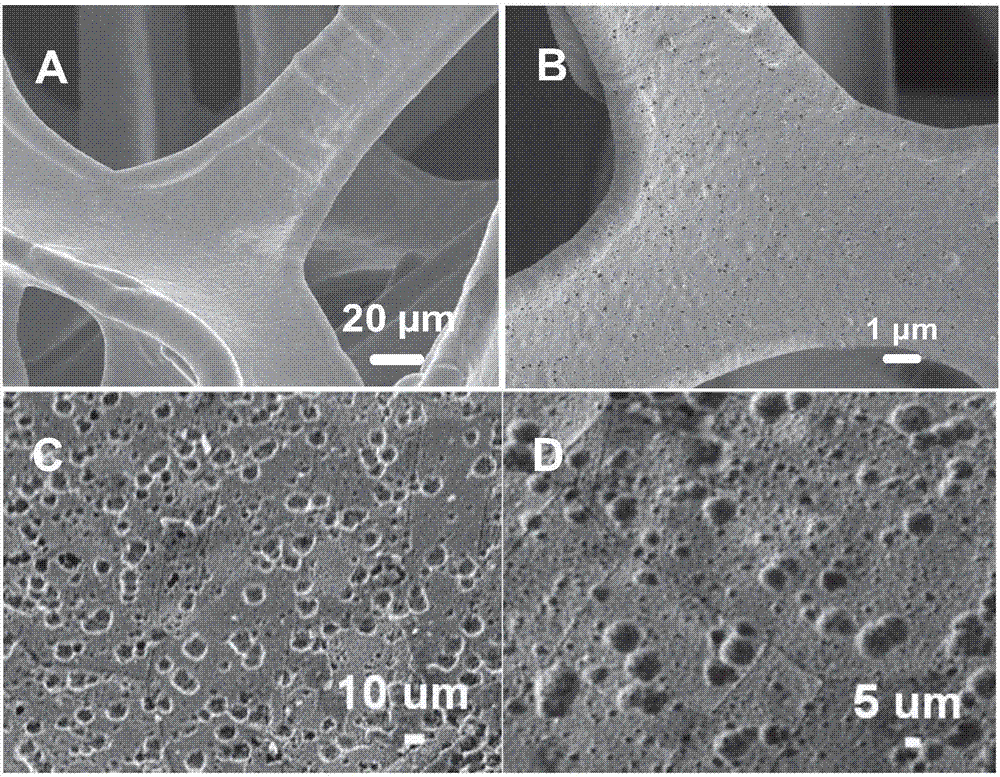

[0031] (1) The morphology and structure of related materials were characterized by scanning electron microscopy ( figure 1 ), the test results show that the obtained composite retains the three-dimensional porous structure of nickel foam, and a large number of micron-sized holes are oxidized and etched on the surface, which is conducive to increasing the specific surface area;

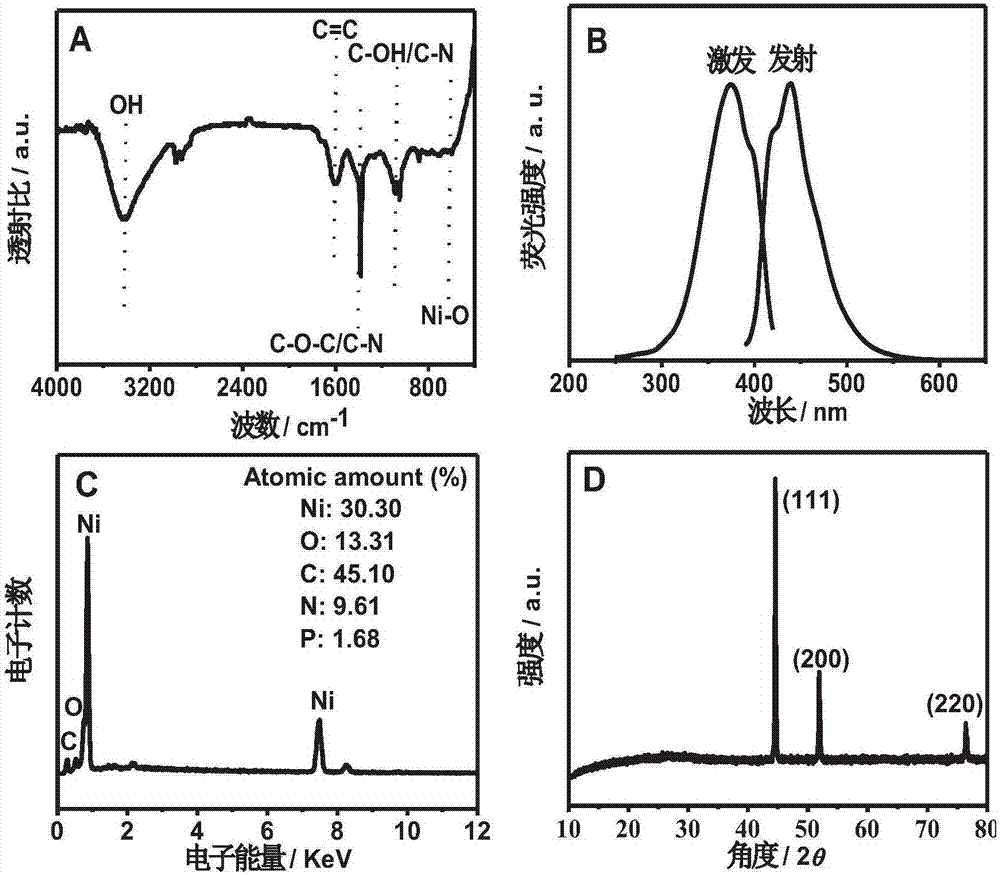

[0032] (2) Fourier-infrared spectroscopy (FT-IR) characterizes the functional groups contained in the material ( figure 2 A), the results show that the resulting composite material contains -COOH, -OH and other functional groups from nitrogen-doped graphene quantum dots and Ni-O groups from nickel oxide, which preliminarily illustrates the formation of the composite;

[0033] (3) Fluorescence characteristics of materials characterized by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com