Catalyst for propane catalytic combustion elimination as well as preparation method and application of catalyst

A catalytic combustion and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of easy carbon deposition and low activity of catalysts, and achieve high price Low cost, high activity, no by-products and few effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

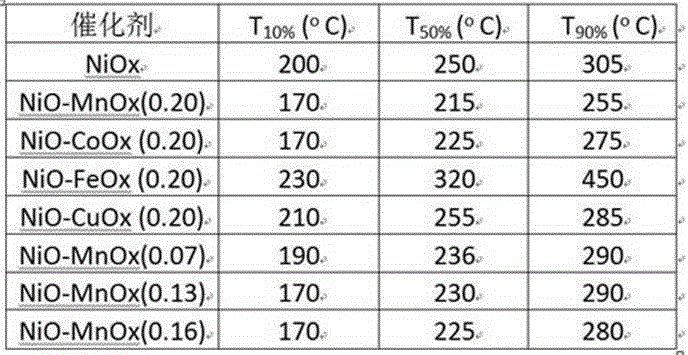

Embodiment 1

[0020] Dissolve commercially available 8.48g sodium carbonate in 40ml water to form a 2mol / L sodium carbonate solution as solution A; get 5ml30% hydrogen peroxide as solution B; dissolve commercially available 5.06g hexahydrate nickel nitrate in 100ml (add 11g95% ethanol) in water to form a 0.2mol / L nickel nitrate solution as solution C; in a water bath at 45°C with stirring, add solutions A and B to solution C drop by drop at the same time to form a precipitate. Stand in the air for 12 hours; filter to get the filter cake, wash the filter cake to about PH = 7, dry in an oven at 110°C for 12 hours, take it out and grind it into powder, then move it to a muffle furnace for roasting. The calcination process is as follows: start heating at 50°C, program temperature rise at a heating rate of 1°C / min, raise the temperature to 350°C, and keep at 350°C for 4 hours to obtain pure nickel oxide catalyst NiOx.

Embodiment 2

[0022] Dissolve commercially available 8.48g sodium carbonate in 40ml water to form a 2mol / L sodium carbonate solution as solution A; get 5ml30% hydrogen peroxide as solution B; commercially available 4.71g hexahydrate nickel nitrate and 0.95g 50% Dissolve the manganese nitrate solution in 40ml of water to form a mixed solution of 0.2mol / L nickel nitrate and manganese nitrate, as solution C; in a water bath at 45°C, under the condition of stirring, add the A and B solutions drop by drop to the C solution at the same time , to form a precipitate, and let it stand in the air at room temperature for 12 hours; filter the filter cake, wash the filter cake to about PH=7, dry it in an oven at 110°C for 12 hours, take it out and grind it into powder, and then transfer it to a muffle furnace for roasting. The calcination process is as follows: start heating at 50°C, program temperature rise at a heating rate of 1°C / min, raise the temperature to 350°C, and keep at 350°C for 4 hours to ob...

Embodiment 3

[0024] Dissolve commercially available 8.48g sodium carbonate in 40ml water to form a 2mol / L sodium carbonate solution as solution A; get 5ml30% hydrogen peroxide as solution B; commercially available 4.65g hexahydrate nickel nitrate and 1.0g tetrahydrate acetic acid Dissolve cobalt in 40ml of water to form a mixed solution of 0.2mol / L nickel nitrate and cobalt acetate, which is used as solution C; in a water bath at 45°C, under stirring conditions, add solutions A and B dropwise to solution C at the same time to form Precipitation, standing in the air at room temperature for 12 hours; filtering to get the filter cake, washing the filter cake to about PH = 7, drying in an oven at 110°C for 12 hours, taking it out and grinding it into powder, and then moving it to a muffle furnace for roasting. The calcination process is as follows: start heating at 50°C, program temperature increase at a heating rate of 1°C / min, raise the temperature to 350°C, and keep at 350°C for 4 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com