Vegetable dehydrating and drying device

A drying device and vegetable dehydration technology, which is applied in the direction of dehydration preservation of fruits/vegetables, food drying, food processing, etc., can solve the problems of affecting product quality, misjudgment of drying degree, and affecting product appearance, so as to improve dehydration and drying. Drying efficiency, avoid tumbling and stirring, improve the effect of ventilation and ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

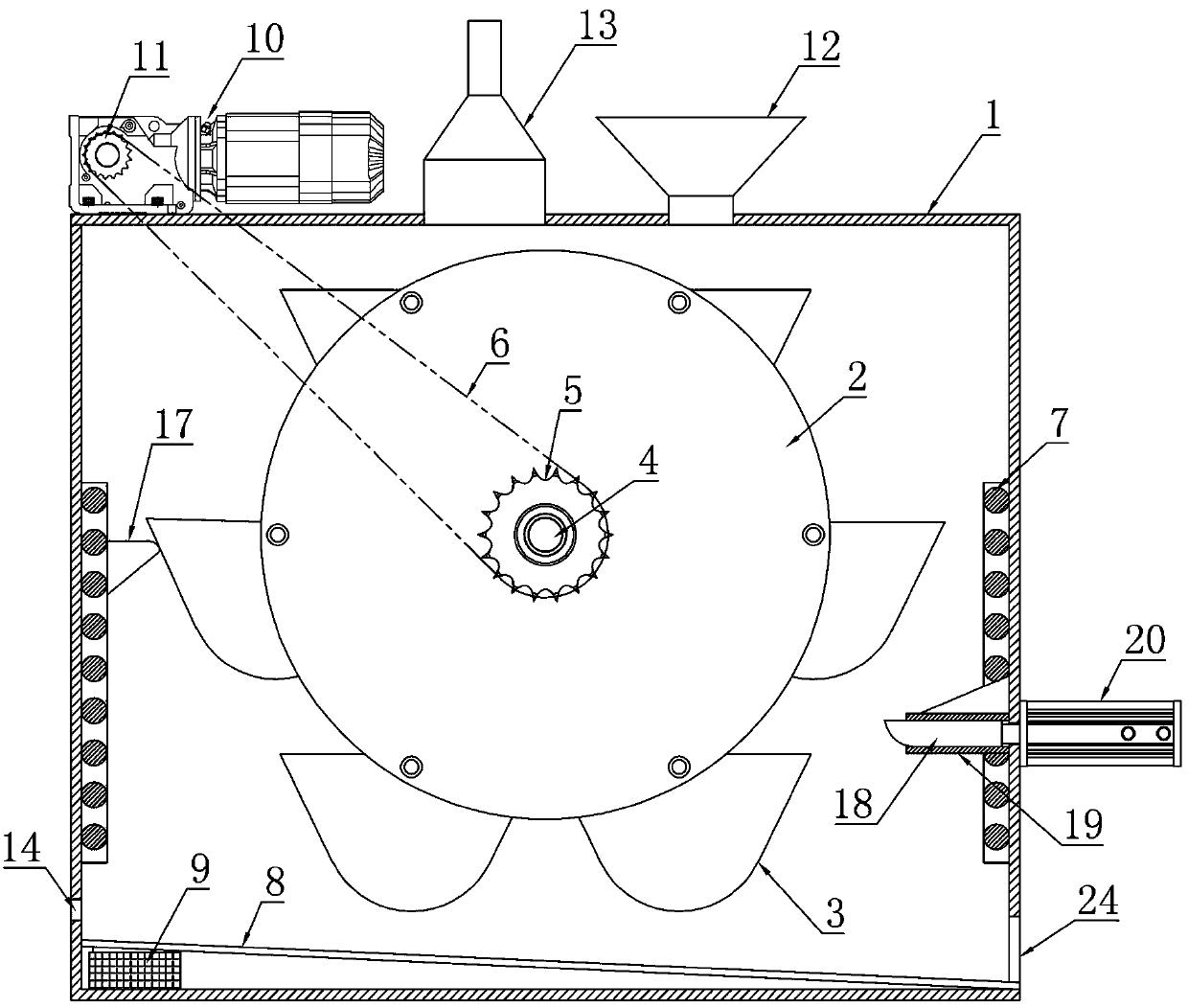

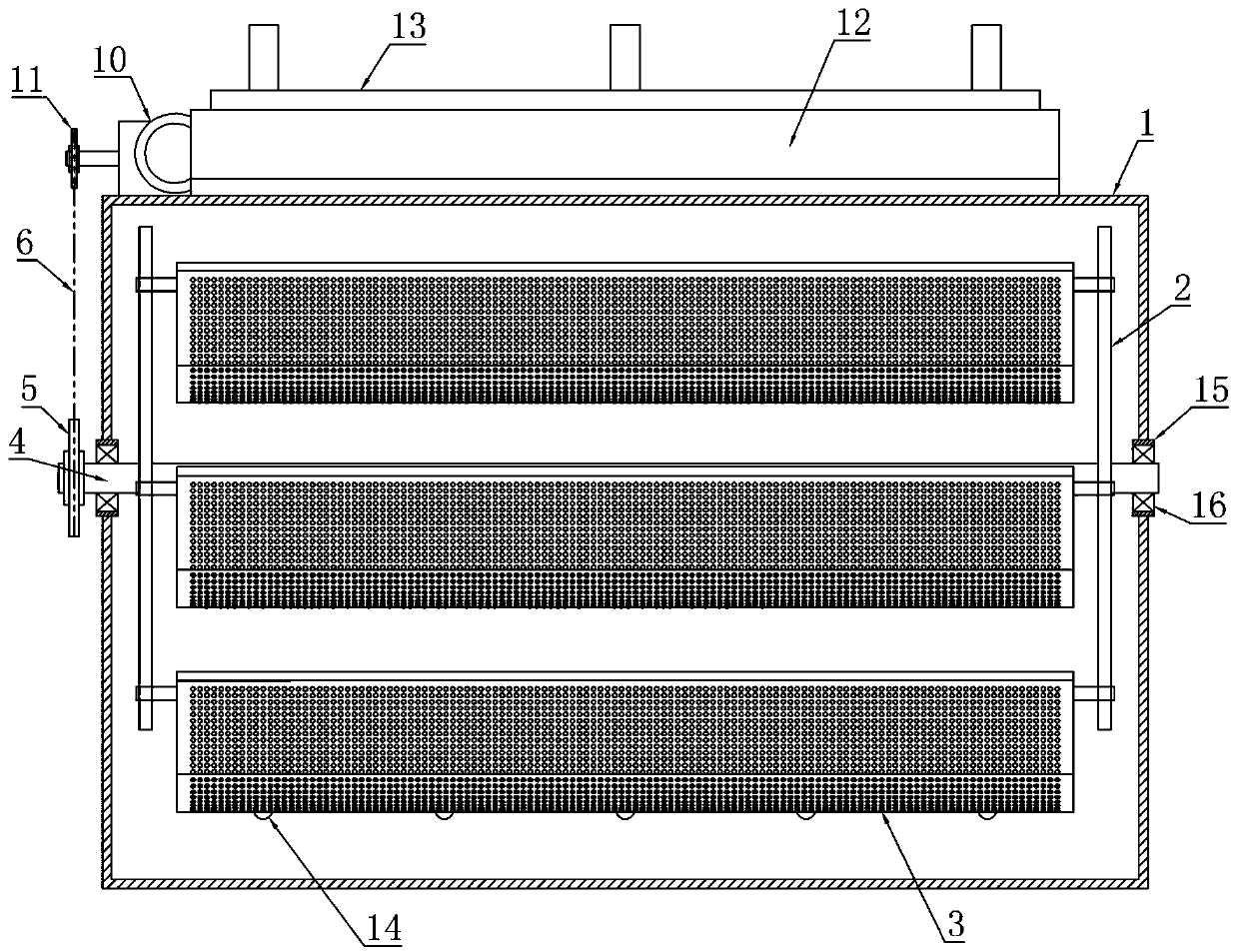

[0032] Such as figure 1 The vegetable dehydration and drying device shown includes a box body 1 and a transmission device 6, and the box body 1 is a drying chamber of the whole device, which plays a role in supporting various parts and separating the inside of the device from the outside world; Inside the box body 1 is installed a shaft 4 that runs through the front side and the back side of the box body 1, and one end of the shaft 4 passing through the box body 1 is equipped with a driven wheel 5, and a motor reducer 10 is installed on the box body 1 , the output shaft of the motor reducer 10 is equipped with a driving wheel 11, the driving wheel 11 is connected with the driven wheel 5 through the transmission device 6, the driving wheel 11 and the driven wheel 5 are sprockets, and the transmission device 6 is The chain is driven by the chain, so that the transmission accuracy is high, the transmission torque is large, and the service life is long; the motor reducer 10 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com