Dehydrogenation catalyst, preparation method and hydrogen release method

A dehydrogenation catalyst and carrier technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of poor catalyst stability, easy sintering and growth of Pt, etc. Achieve the effects of reducing surface acidity, inhibiting carbon deposition, and hydrogen storage safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

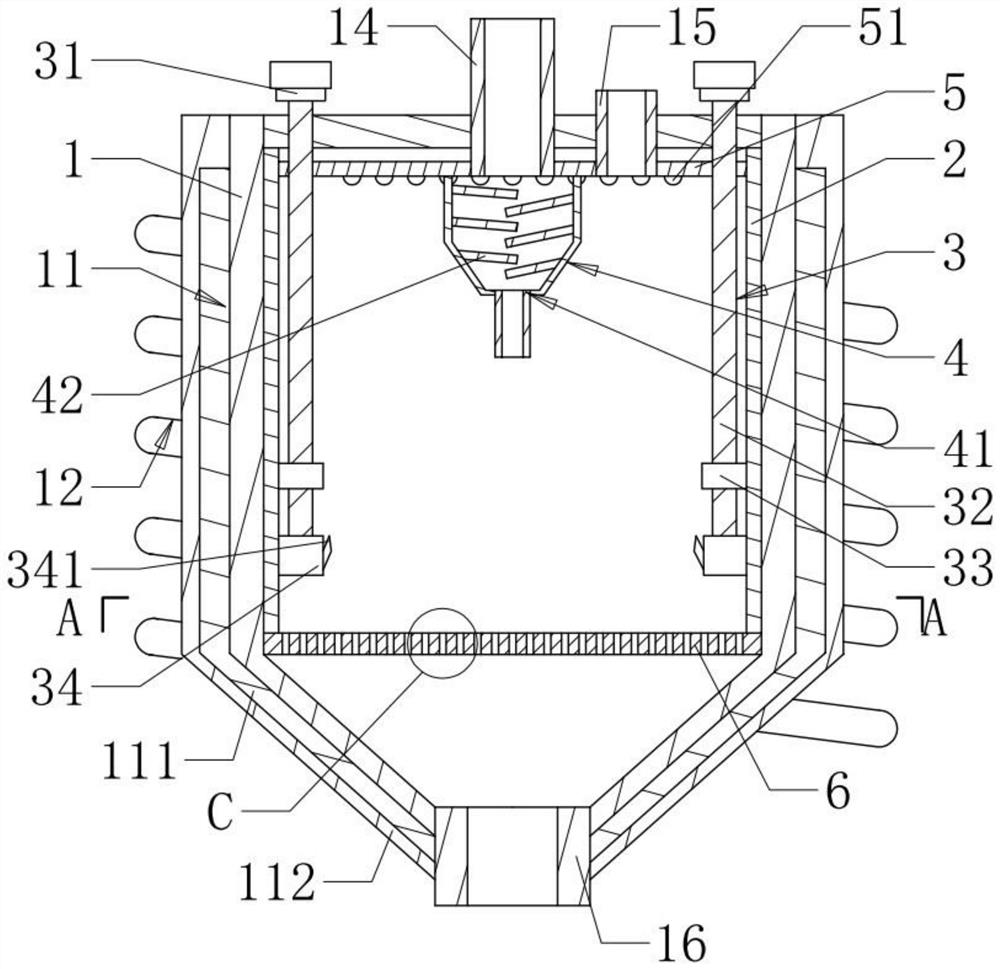

[0034] A method for preparing a dehydrogenation catalyst, which is made by using a preparation device for a dehydrogenation catalyst, comprising the steps of:

[0035] Step 1: Prepare the bimetallic alloy nano-colloid of the active component by the liquid phase reduction method; specifically: dissolve the protective agent with controllable size of the nano-particle size in water, stir until it is completely dissolved; dissolve the soluble platinum salt or acid precursor and another soluble salt precursor of Group VIII transition non-noble metal elements are dissolved in the above solution, fully stirred to form a uniform solution; the alkali solution is added to the above solution, and the pH is adjusted to 10-11; finally, a reducing agent is added to the above solution , kept stirring, and reacted for 2 hours to obtain bimetallic alloy nanocolloids;

[0036] Step 2: Prepare spinel carrier by co-precipitation method or sol-gel method;

[0037] Step 3: mixing the bimetallic na...

Embodiment 1

[0046] The following is a small-scale test for preparing a dehydrogenation catalyst according to the present invention.

[0047] (1) Preparation of catalyst:

[0048]Fully dissolve 0.5g of polyvinylpyrrolidone PVP in 75ml of water, then mix 2ml of chloroplatinic acid solution (platinum content of 0.015g / ml) and 0.0306g of FeNCl 2 4H 2 O was added to the above solution and stirred fully. Under the mechanical stirring of 400r / min, 0.1M NaOH solution was added dropwise until the pH value of the system reached about 10, then 10 ml of 1M potassium borohydride solution was added, kept stirring for 2 hours, and then 3g Prepared Ca 0.2 Mg 0.8 al 2 o 4 Add spinel carrier powder to the above colloid for 3 hours of adsorption, then filter and wash the solid, vacuum-dry at 60°C for 12 hours, then bake at 800°C for 4 hours in a nitrogen atmosphere, and finally bake at 400°C for 4 hours in an air atmosphere to obtain the active Pt1Fe1 / Ca with a total metal content of 1.35 wt% 0.2 Mg ...

Embodiment 2

[0052] (1) Catalyst preparation:

[0053] The catalyst support was replaced by Ba 0.2 Mg 0.8 al 2 o 4 , other are with embodiment 1, and catalyzer is recorded as No. 2.

[0054] (2) Evaluation conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com