Bimetallic acid-free aluminosilicate porous composite material for direct aromatization of n-alkanes as well as preparation method and application of bimetallic acid-free aluminosilicate porous composite material

A porous composite material, n-alkane technology, applied in the field of petroleum refining, can solve the problems of low selectivity of target products, high coking, fast catalyst deactivation, etc., and achieve the effects of good atom economy and low coke production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

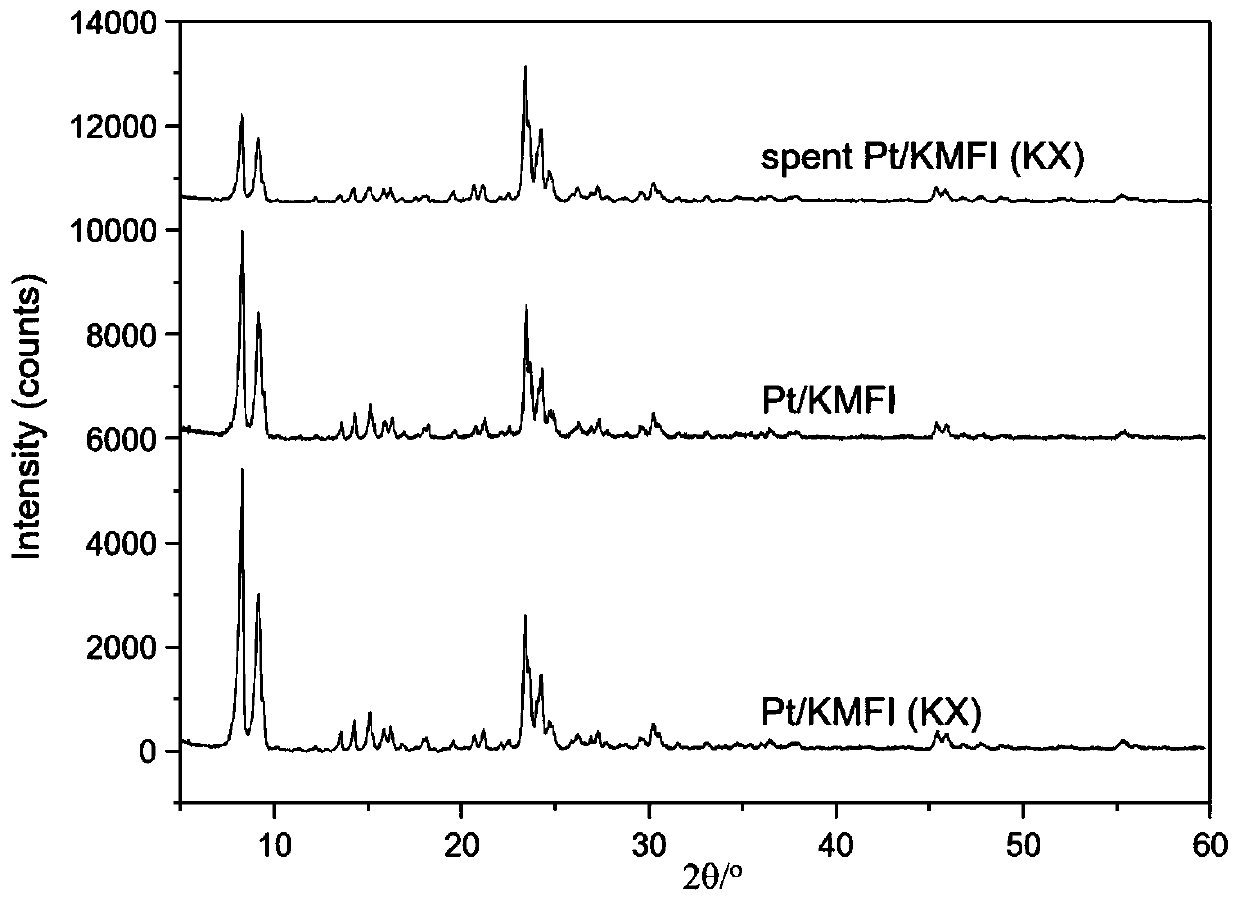

[0048] Example 1: Pt / KMFI (80:1)

[0049] Its preparation process is as follows:

[0050] 1) Al(NO 3 ) 3 9H 2 O was dissolved in tetrapropylammonium hydroxide (TPAOH, 40wt%) and stirred continuously at room temperature until Al(NO 3 ) 3 9H 2 O is completely dissolved.

[0051] 2) Add tetraethyl silicate (TEOS) dropwise to the solution prepared in step 1), and keep stirring. where Al 2 o 3 :SiO2 2 :TPAOH:H 2 The molar ratio of O is 1:80:21:943.

[0052] 3) The mixture prepared in step 2) was continuously stirred for 2 hours until a gel was formed. Then the obtained gel was transferred to a hydrothermal synthesis tank and kept at a constant temperature of 170 °C for 3 days. After natural cooling to room temperature, the product material in the solution can be separated by freeze-drying and the resulting solid substance recovered.

[0053] 4) Wash the solid matter in step 3) with deionized water for 3 times, then dry at 110°C for 12 hours at a pressure of 0.9 atmosp...

Embodiment 2

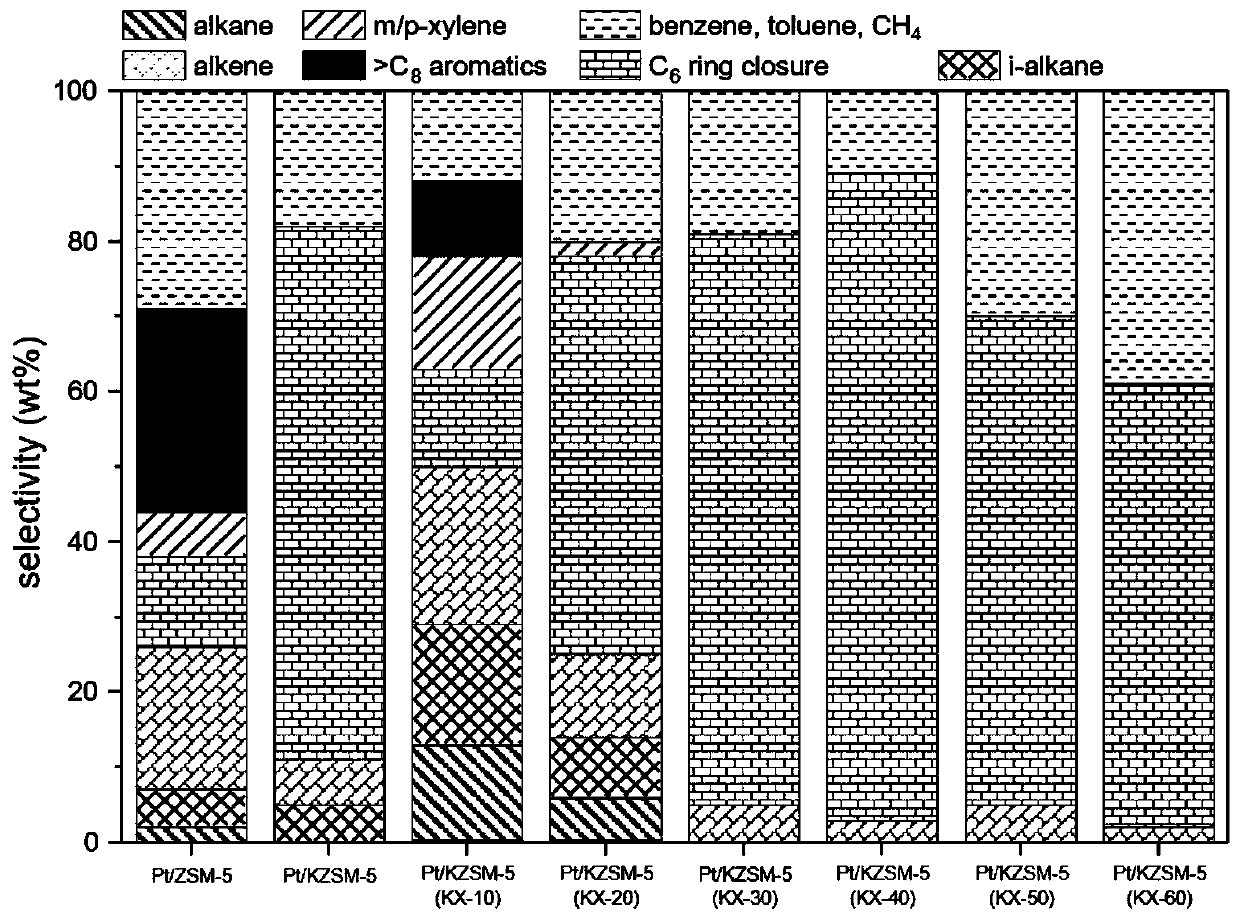

[0060] Embodiment 2: Pt / KMFI (KX-40) (silicon to aluminum ratio is 80:1)

[0061] Its preparation process is as follows:

[0062] 1) Al(NO 3 ) 3 9H 2 O was dissolved in tetrapropylammonium hydroxide (TPAOH, 40wt%) and stirred continuously at room temperature until Al(NO 3 ) 3 9H 2 O is completely dissolved.

[0063] 2) Add tetraethyl silicate (TEOS) dropwise to the solution prepared in step 1), and keep stirring. where Al 2 o 3 :SiO2 2 :TPAOH:H 2 The molar ratio of O is 1:80:21:943. During this process, a certain amount of KNO is added to the mixture 3 , so that the mass of K is Al 2 o 3 with SiO 2 4% of the total mass.

[0064] 3) The mixture prepared in step 2) was continuously stirred for 2 hours until a gel was formed. Then the obtained gel was transferred to a hydrothermal synthesis tank and kept at a constant temperature of 170 °C for 3 days. After natural cooling to room temperature, the product material in the solution can be separated by freeze-dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com