TiH2 doped Mg/ polymethyl methacrylate (PMM) composite material and preparation method

A composite material and charge technology, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problems of restricting popularization and application, poor hydrogen absorption and desorption performance at low temperature, etc., and achieve low price, easy operation, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: with TiH 2 as a catalyst for MgH 2 / PMMA for doping.

[0022] Weigh 0.2g TiH respectively in the glove box 2 and 1.0 g MgH 2 , put it into a ball mill jar with a capacity of 100mL, put 20 steel balls with a diameter of 10 mm into the ball mill jar, and ensure that the ball-to-material ratio is 100:1. Put the ball mill jar in the ball mill, set the rotation speed to 400 r / min, and the time is 4 hours, and the final sample obtained is MgH 2 -TiH 2 Material.

[0023] Weigh 1.0 g of the above sample in the glove box, put it in a 50 mL Erlenmeyer flask, add 20 mL of anhydrous THF, and then add 0.3 g of PMMA material. Seal the Erlenmeyer flask, and after ultrasonication for 0.5 hours, vacuum-dry at 50°C for 12 hours, and finally vacuum-dry at room temperature for 5 hours to obtain TiH 2 Doped MgH 2 / PMMA sample

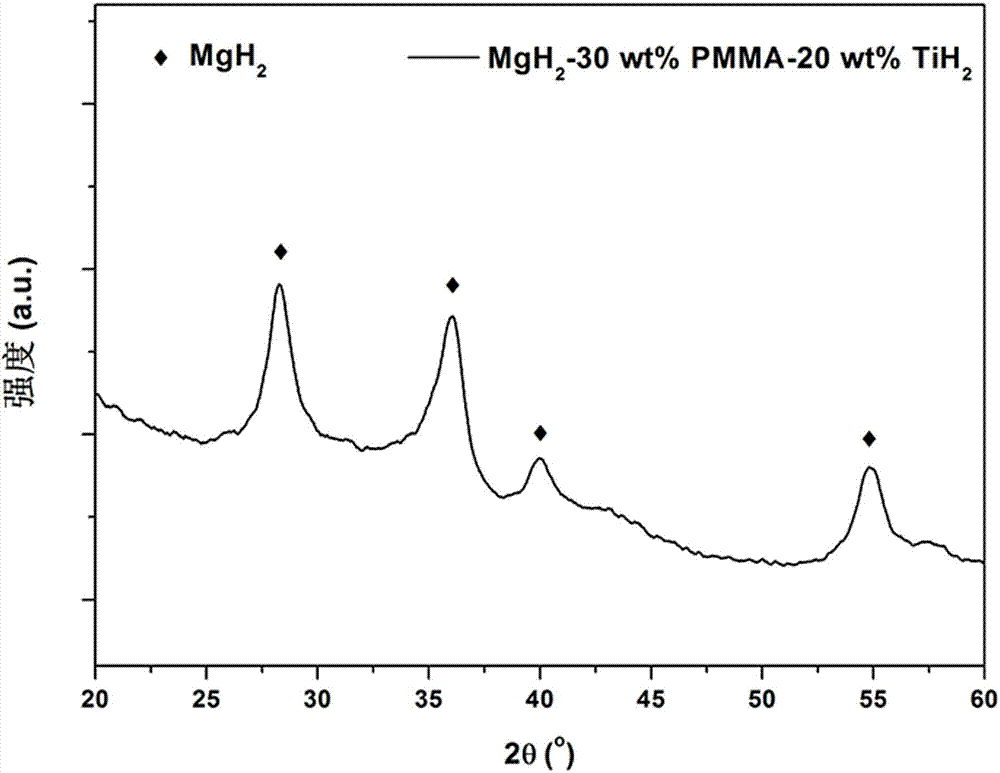

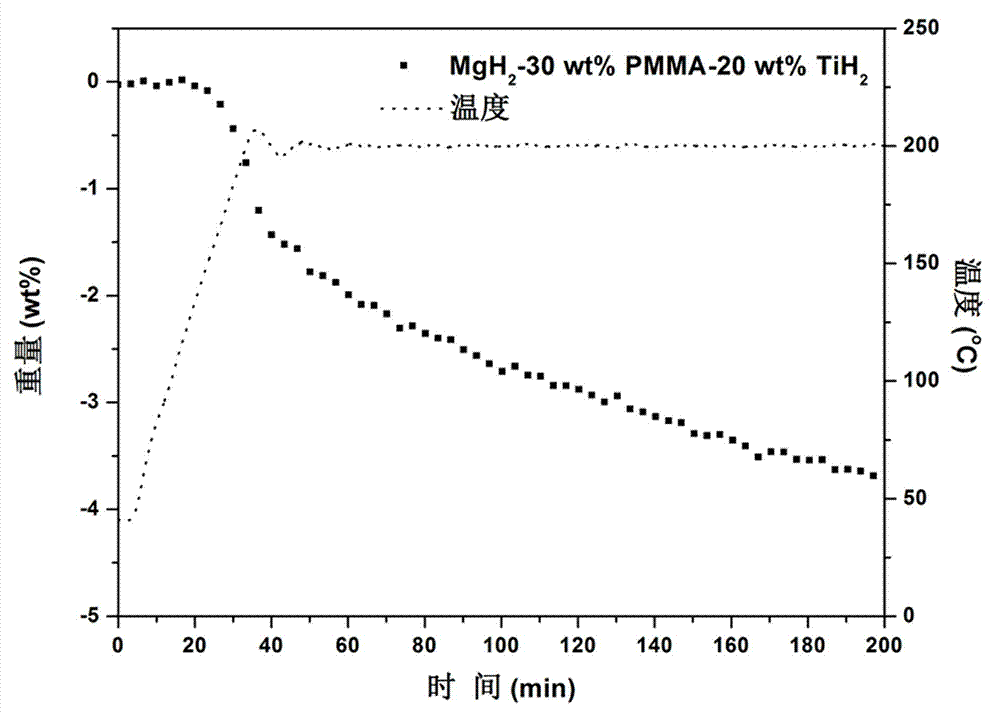

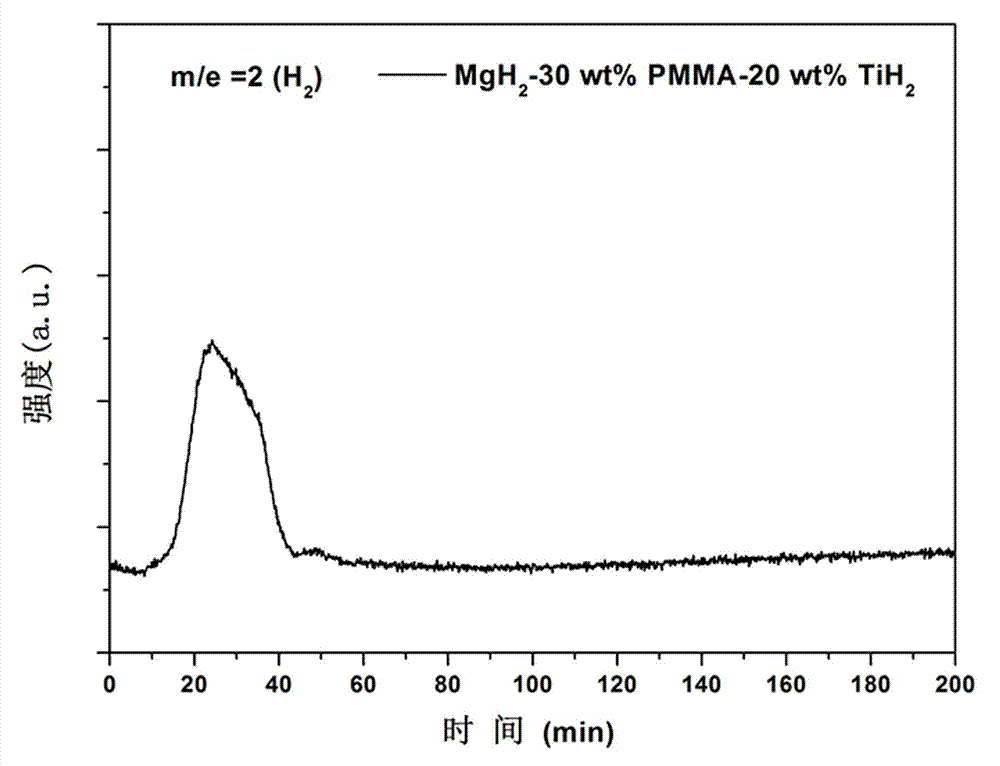

[0024] MgH doped with catalyst 2 XRD characterization of / PMMA composites

[0025] For the prepared MgH doped with catalyst 2 / PMMA for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com