Hydrogenation and dehydrogenation catalyst as well as preparation method and application thereof

A dehydrogenation catalyst and chemical formula technology, applied in the field of hydrogenation catalysts, can solve the problems of high energy density, achieve the effect of high hydrogen storage energy density, low dehydrogenation temperature, and increase the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of hydrogenation and dehydrogenation catalyst of the present embodiment, it comprises the following steps:

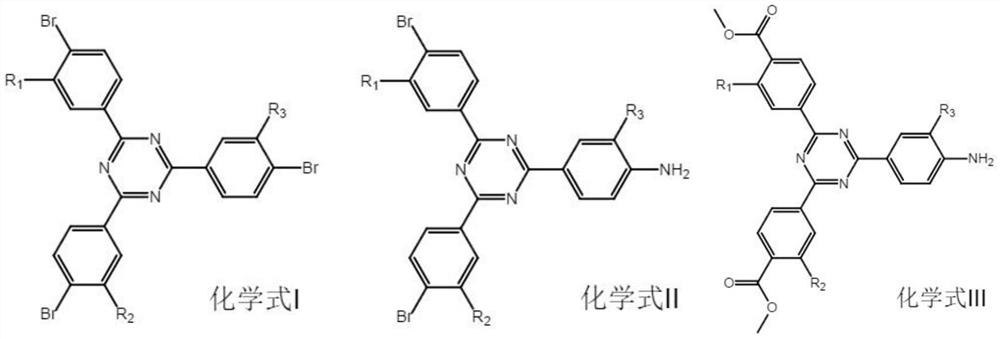

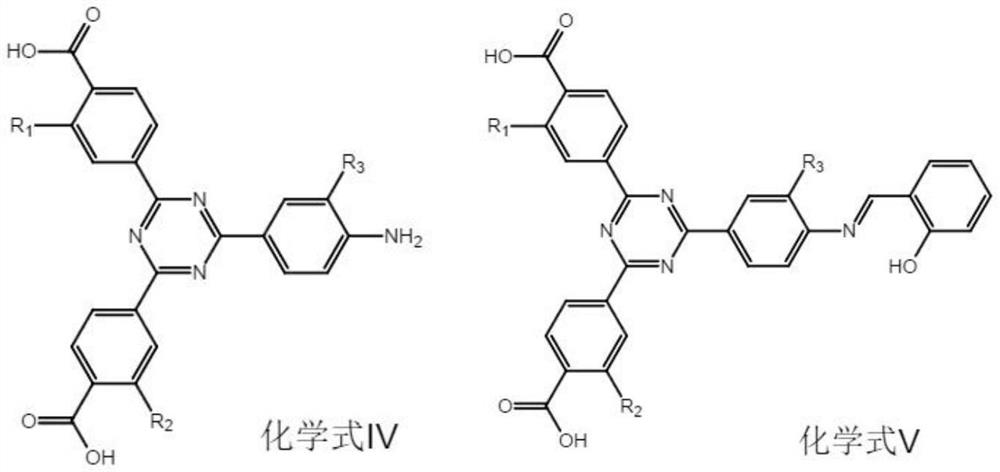

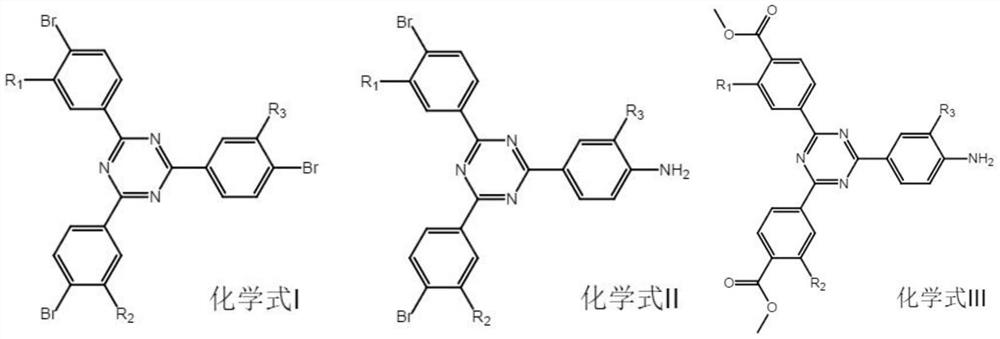

[0030] Step S1: the triazine compound 2,4,6-tris(4-bromophenyl)-1,3,5-triazine shown in chemical formula I and ammonia in N,N-dimethylformamide and cuprous oxide The amination reaction is carried out under the presence of the chemical formula II to obtain the triazine compound shown in the chemical formula II; the mass ratio of the N,N-dimethylformamide to the triazine compound shown in the chemical formula I is 5:1, and the oxysubstance The mass ratio of copper to the triazine compound shown in the chemical formula I is 0.3:1, and the molar ratio of the ammonia water to the triazine compound shown in the chemical formula I is 1.2:1;

[0031]

[0032] Step S2: adding the triazine compound shown in the chemical formula II with a molar concentration of 100mmol / L obtained in step S1 into a methanol solution with a molar concentration of 10m...

Embodiment 2

[0041] The preparation method of hydrogenation and dehydrogenation catalyst of the present embodiment, it comprises the following steps:

[0042] Step S1: the triazine compound 2,4,6-tris(4-bromophenyl)-1,3,5-triazine shown in chemical formula I and ammonia in N,N-dimethylformamide and cuprous oxide The amination reaction is carried out in the presence of the chemical formula II to obtain the triazine compound shown in the chemical formula II; the mass ratio of the N,N-dimethylformamide to the triazine compound shown in the chemical formula I is 2:1, and the oxysubstance The mass ratio of copper to the triazine compound shown in the chemical formula I is 0.1:1, and the molar ratio of the ammonia water to the triazine compound shown in the chemical formula I is 1:1;

[0043]

[0044] Step S2: adding the triazine compound shown in the chemical formula II with a molar concentration of 50mmol / L obtained in step S1 into a methanol solution with a molar concentration of 5mmol / L p...

Embodiment 3

[0052] The preparation method of hydrogenation and dehydrogenation catalyst of the present embodiment, it comprises the following steps:

[0053] Step S1: the triazine compound 2,4,6-tris(4-bromophenyl)-1,3,5-triazine shown in chemical formula I and ammonia in N,N-dimethylformamide and cuprous oxide The amination reaction is carried out under the presence of the chemical formula II to obtain the triazine compound shown in the chemical formula II; the mass ratio of the N,N-dimethylformamide to the triazine compound shown in the chemical formula I is 8:1, and the oxyethylene The mass ratio of copper to the triazine compound shown in the chemical formula I is 0.5:1, and the molar ratio of the ammonia water to the triazine compound shown in the chemical formula I is 1.2:1;

[0054]

[0055] Step S2: adding the triazine compound shown in the chemical formula II with a molar concentration of 200mmol / L obtained in step S1 into a methanol solution with a molar concentration of 20mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com