K2TiF6 doped Mg/PMMA composite material and preparation method thereof

A composite material and charging amount technology, applied in hydrogen production and other directions, can solve the problems of poor low-temperature hydrogen absorption and desorption performance, restricting popularization and application, etc., and achieve the effects of easy operation, low price, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

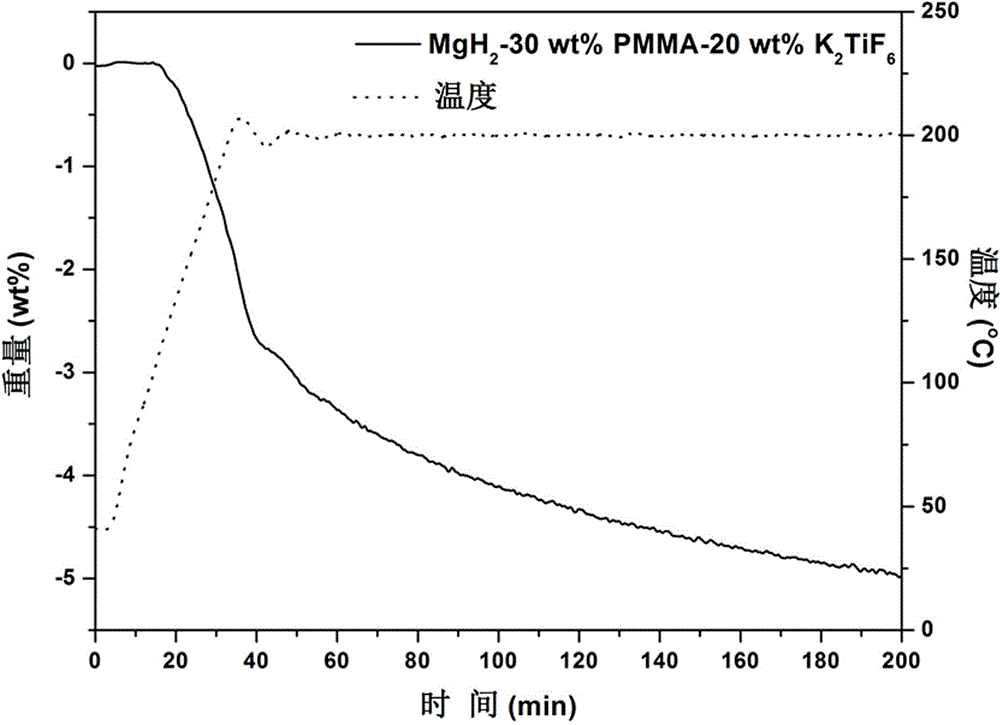

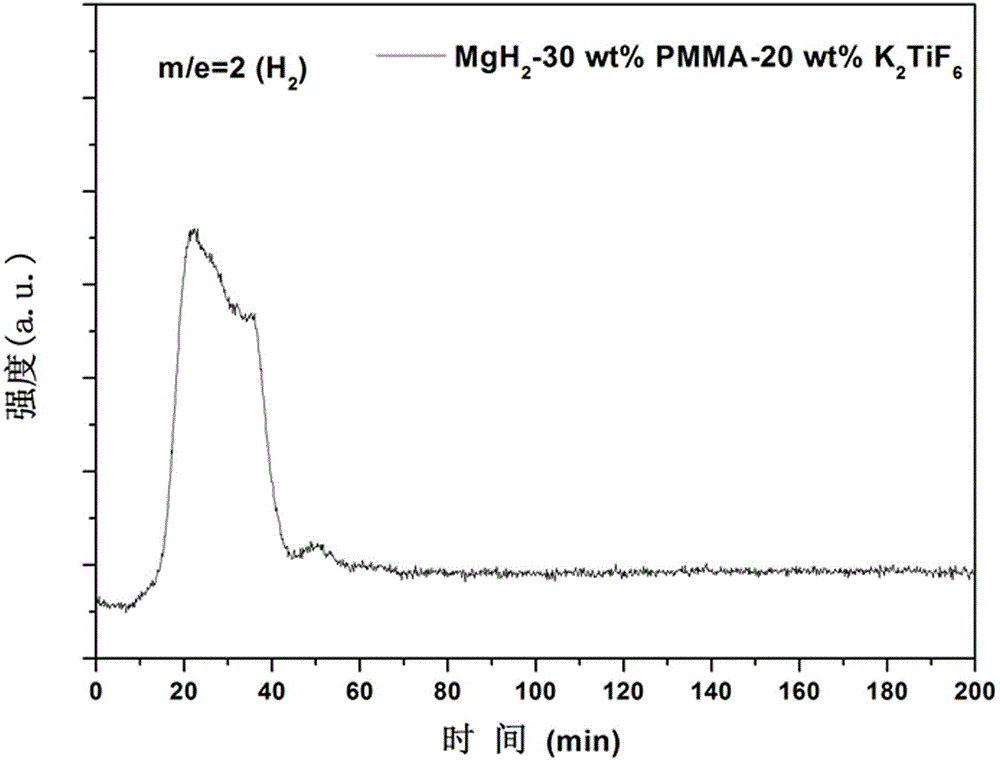

[0021] Example: with K 2 TiF 6 as a catalyst for MgH 2 / PMMA for doping.

[0022] Weigh 0.2g K in the glove box 2 TiF 6 and 1.0 g MgH 2 , put it into a ball mill jar with a capacity of 100mL, put 20 steel balls with a diameter of 10 mm into the ball mill jar, and ensure that the ball-to-material ratio is 100:1. Put the ball mill jar in the ball mill, set the rotation speed to 400 r / min, and the time is 4 hours, and the final sample obtained is MgH 2 -K 2 TiF 6 Material.

[0023] Weigh 1.0 g of the above sample in the glove box, put it in a 50 mL Erlenmeyer flask, add 20 mL of anhydrous THF, and then add 0.3 g of PMMA material. The Erlenmeyer flask was sealed, then ultrasonicated for 0.5 hours, then vacuum-dried at 50°C for 12 hours, and finally vacuum-dried at room temperature for 5 hours to obtain K 2 TiF 6 Doped MgH 2 / PMMA sample

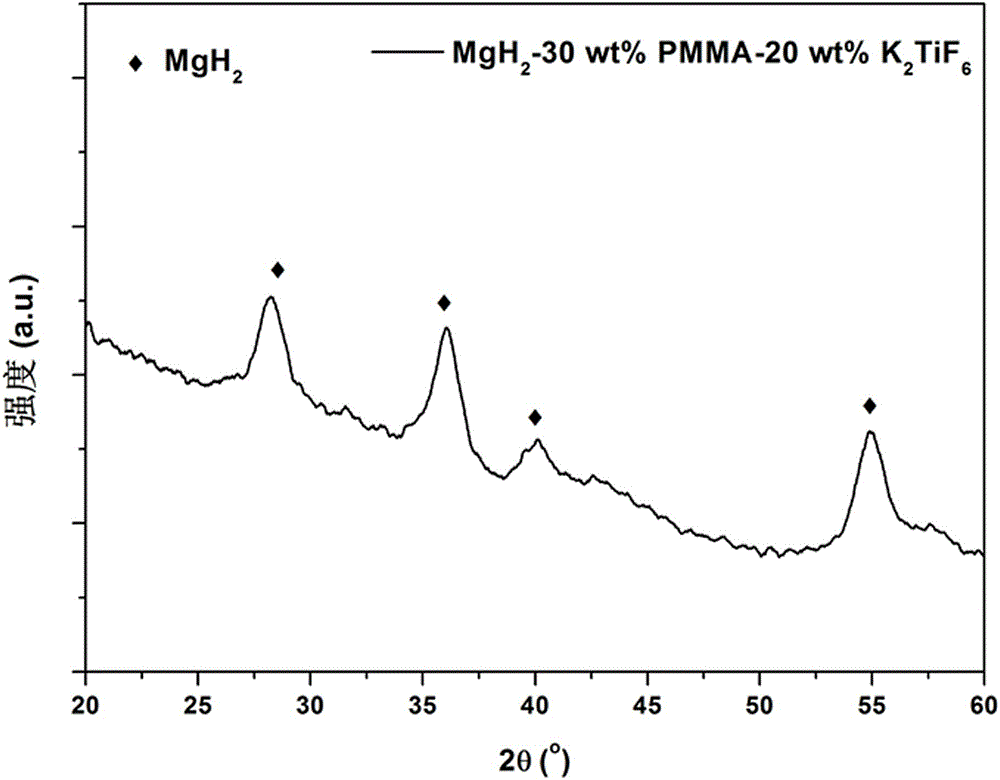

[0024] MgH doped with catalyst 2 XRD characterization of / PMMA composites

[0025] For the prepared MgH doped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com