Method for remediate waste oil-based drilling fluid sediments through combination of engineering bacteria and plants

An oil-based drilling fluid and joint remediation technology, applied in the restoration of polluted soil, etc., can solve the problems of low treatment efficiency and secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

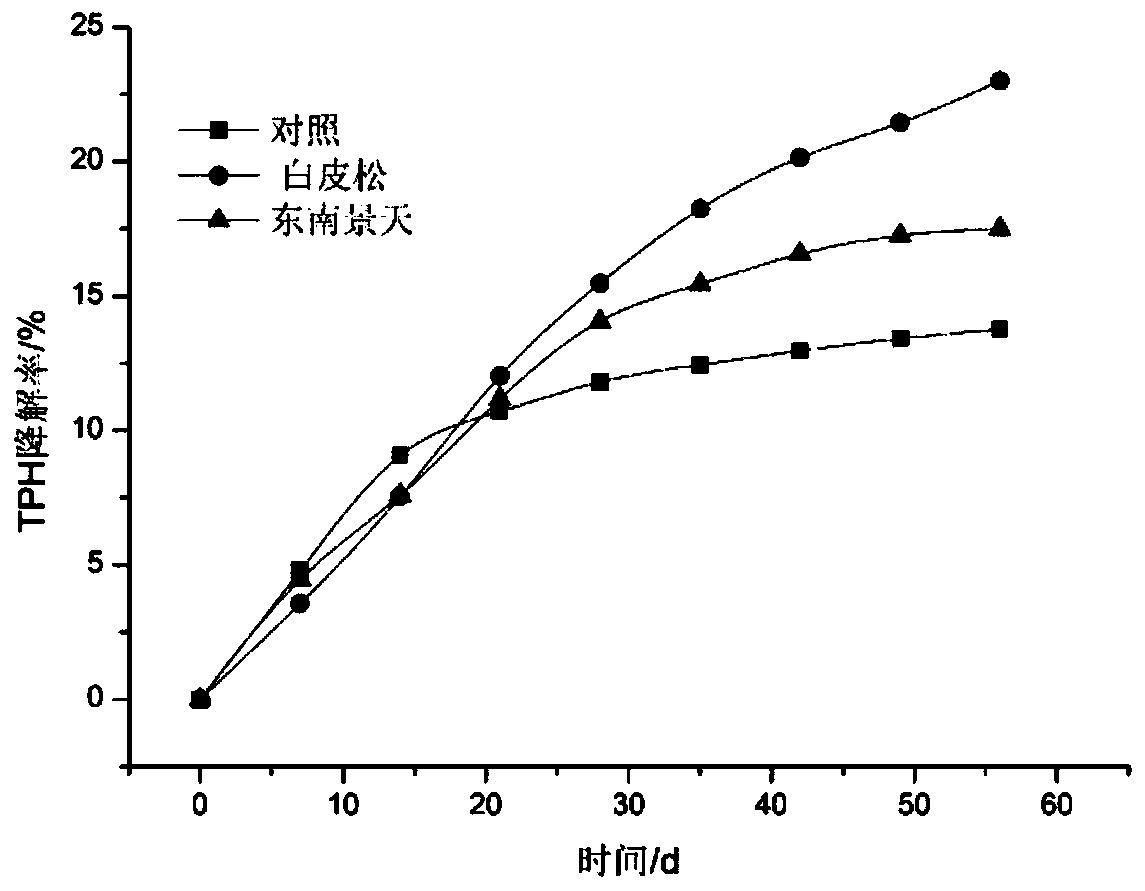

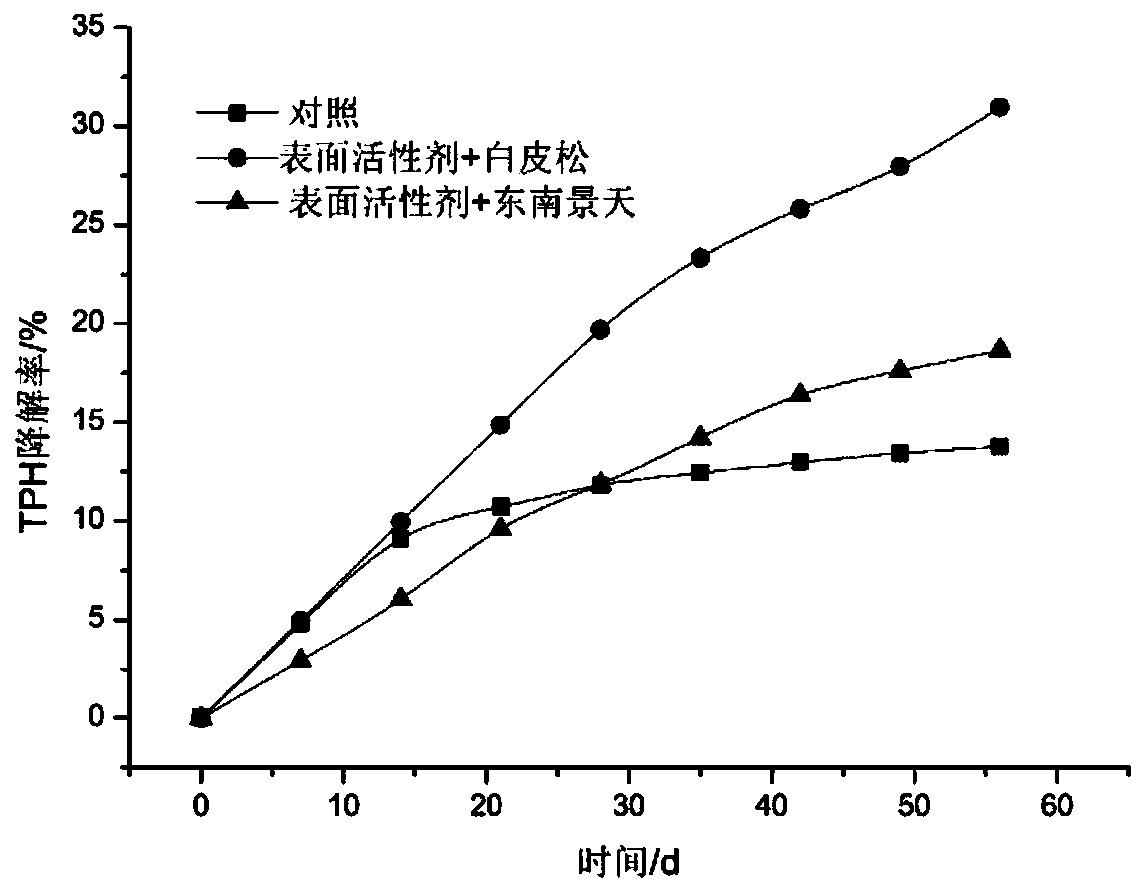

Embodiment 1

[0032] Mix clean soil with a humidity of 35%, a pH of 8, and a particle size of 0.005 mm to 1.5 mm with waste oil-based drilling fluid sediments at a ratio of 1:1 to prepare about 300 kg of experimental soil samples, and add SQ to the mixed soil samples -1 engineering bacteria 0.2mg.kg -1 , SQ-2 engineering bacteria 0.1mg.kg -1 , and then add 0.1mg.kg -1 NH 4 NO 3 Solid powder and 0.1mg.kg -1 KH 2 PO 4As a nitrogen source and a phosphorus source (both sprayed and stirred in the prepared soil in a water-soluble manner), the SQ-1 engineering bacteria are used to emulsify and degrade petroleum hydrocarbons and reduce the biological toxicity of petroleum hydrocarbons. Acinetobacter bacteria, Flavobacterium, Corynebacterium, Achromobacter, Bacillus, lipase, amylase, protease according to 1:1:0.5:1:1:0.3:0.5 : the mixture that the mass ratio of 1 forms; Described SQ-2 engineering bacterium is made of sphingobacterium (Sphingobacterium), alcanivorax (Alcanivorax), solution rin...

Embodiment 2

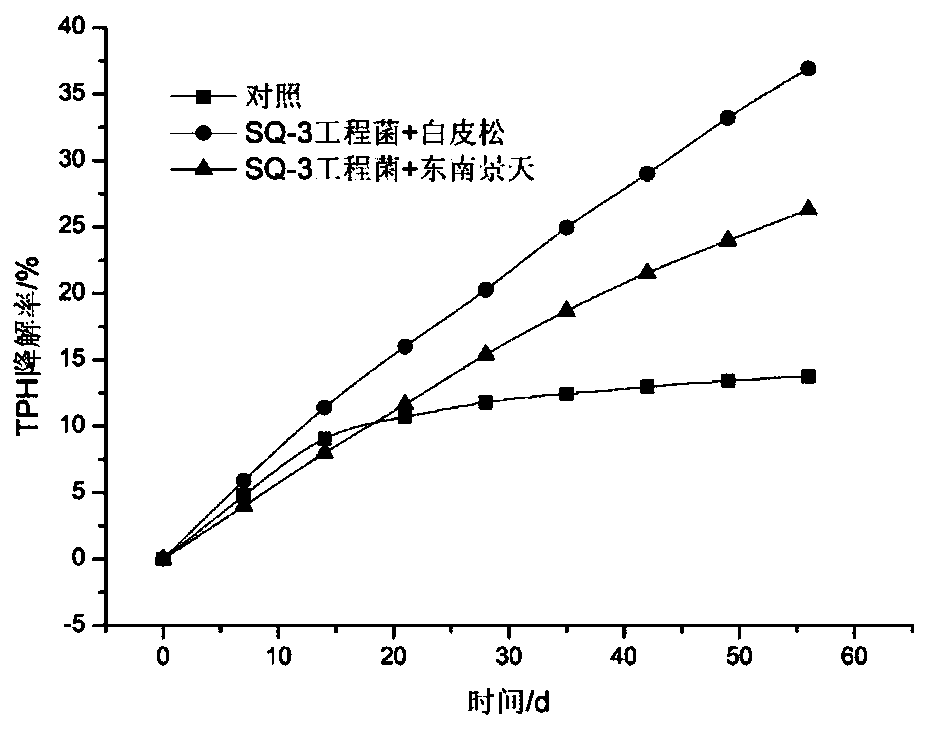

[0034] The difference from Example 1 is that the SQ-3 engineering bacteria of 0.1mL / kg has also been added, and the SQ-3 engineering bacteria are composed of Arthrobacter, Alcaligenes, Micrococcus ( Micrococcus), Nocardia, Mycobacterium; Aeromonas, Nocardia, Candida according to 1:4.3:0.1 :0.1:4:2:0.2:0.1 mass ratio composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com