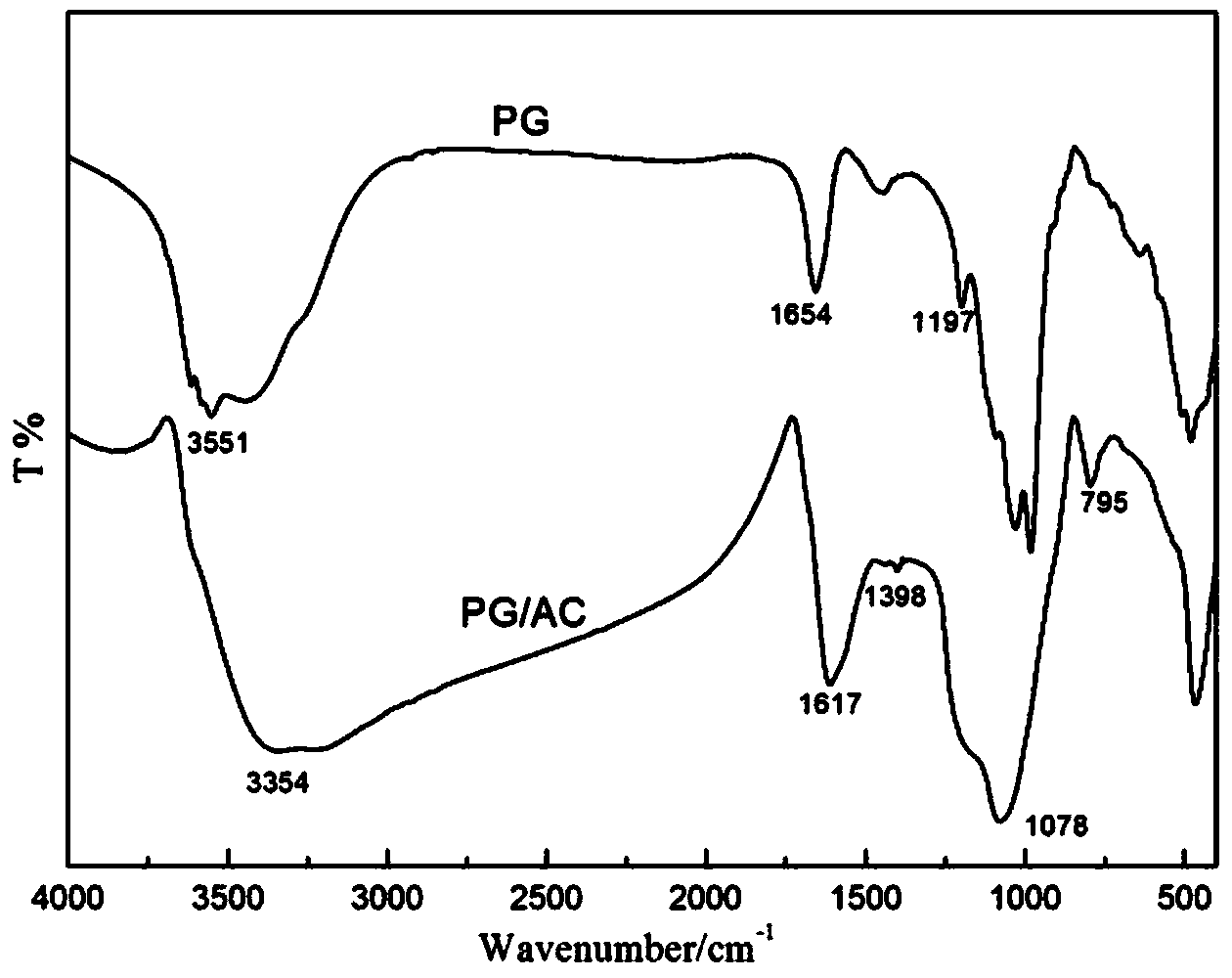

Method for preparing attapulgite/carbon composite adsorbent by one-step carbonization-activation

A carbon composite material, attapulgite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effects of easy availability of raw materials, improved pore structure, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 3gZnCl 2 Dissolve the solid in water, take 0.5g of previously pulverized attapulgite powder and 1g of cellulose, add to ZnCl 2 In the solution, stir or ultrasonically disperse evenly, immerse for 8 hours and dry to obtain the sample.

[0027] Place the dried sample in a horizontal tube furnace, raise the temperature to 450°C at 5°C / min, and keep the temperature for 30min. After cooling to room temperature, wash with 1.2mol / L hydrochloric acid solution, and then wash with hot water at 70°C until the pH is 7. After drying at 60°C, the activated composite product, attapulgite / carbon composite material, is obtained.

[0028] The BET specific surface area of the resulting activated composite product is 990m 2 / g, which is higher than the specific surface area of attapulgite raw ore and activated carbon (see Table 3).

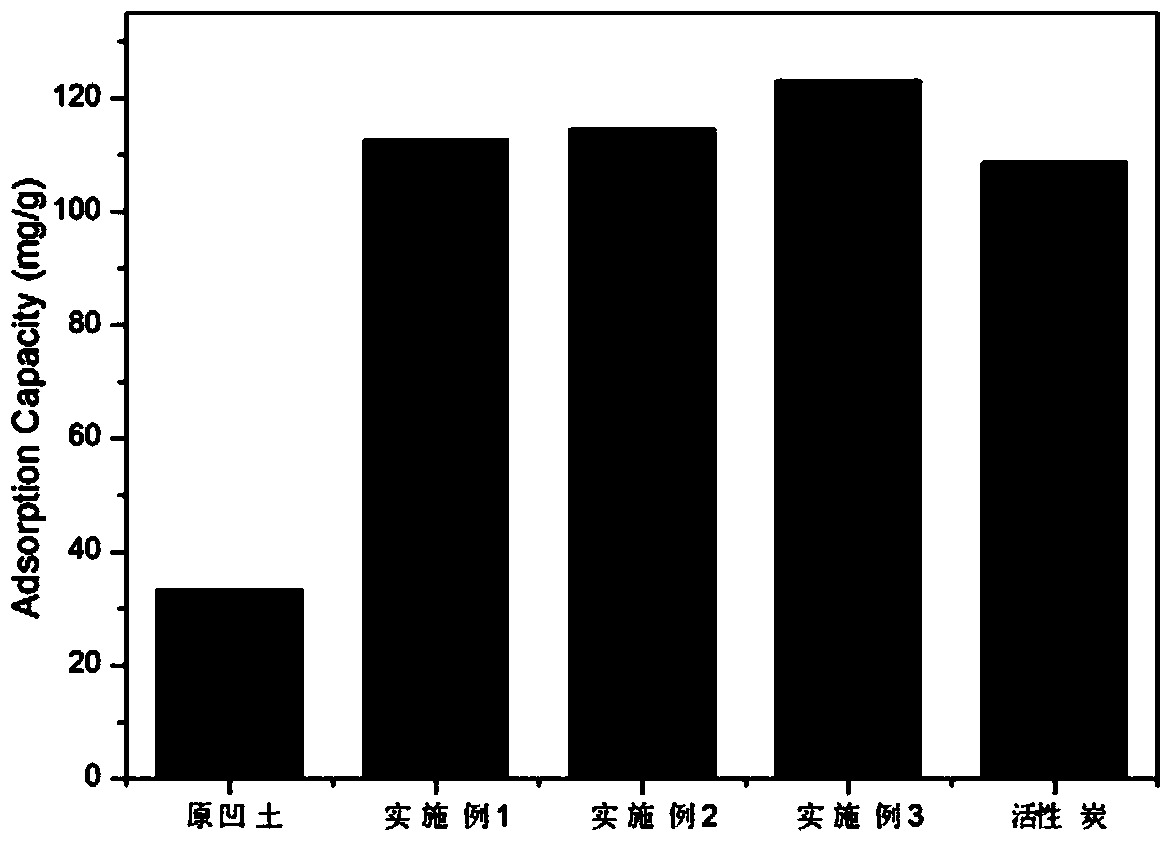

[0029] Take the methylene blue solution with an initial concentration of 50mg / L as the organic pollutant, activate the composite modified attapu...

Embodiment 2

[0031] Weigh 3gZnCl 2 Dissolve the solid in water, take 0.5g of previously pulverized attapulgite powder and 1g of cellulose, add to ZnCl 2 In the solution, stir or ultrasonically disperse evenly, dry after 24 hours of immersion.

[0032] The dried samples were placed in a horizontal tube furnace, the temperature was raised to 600°C at 5°C / min, and the temperature was kept for 2h. After cooling to room temperature, wash with 1.2mol / L hydrochloric acid solution, and then wash with hot water at 70°C until the pH is 7. After drying at 60°C, the activated composite product, attapulgite / carbon composite material, is obtained.

[0033] The BET specific surface area of the resulting activated composite product is 1478m 2 / g, which is higher than the specific surface area of attapulgite raw ore and activated carbon (see Table 3).

[0034] Take the methylene blue solution with an initial concentration of 50mg / L as the organic pollutant, activate the composite modified attapulgite...

Embodiment 3

[0036] Weigh 1gZnCl 2 Dissolve the solid in water, take 0.5g of previously pulverized attapulgite powder and 1g of cellulose, add to ZnCl 2 In the solution, stir or ultrasonically disperse evenly, immerse for 12 hours and then dry.

[0037] The dried samples were placed in a horizontal tube furnace, the temperature was raised to 450°C at 5°C / min, and the temperature was kept for 1h. After cooling to room temperature, wash with 1.2mol / L hydrochloric acid solution, and then wash with hot water at 70°C until the pH is 7. After drying at 60°C, the activated composite product, attapulgite / carbon composite material, is obtained.

[0038] The BET specific surface area of the resulting activated composite product is 1139 m 2 / g, which is higher than the specific surface area of attapulgite raw ore (see Table 3).

[0039] Take the methylene blue solution with an initial concentration of 50mg / L as the organic pollutant, activate the composite modified attapulgite / carbon composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Equilibrium adsorption | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com