Catalyst and preparation method and application thereof

A catalyst and template technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of poor propylene selectivity and thermal stability, catalyst stability and catalytic efficiency need to be improved, metal atom sintering Reunion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

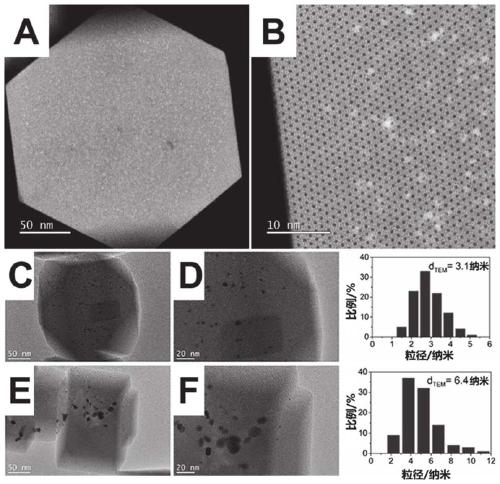

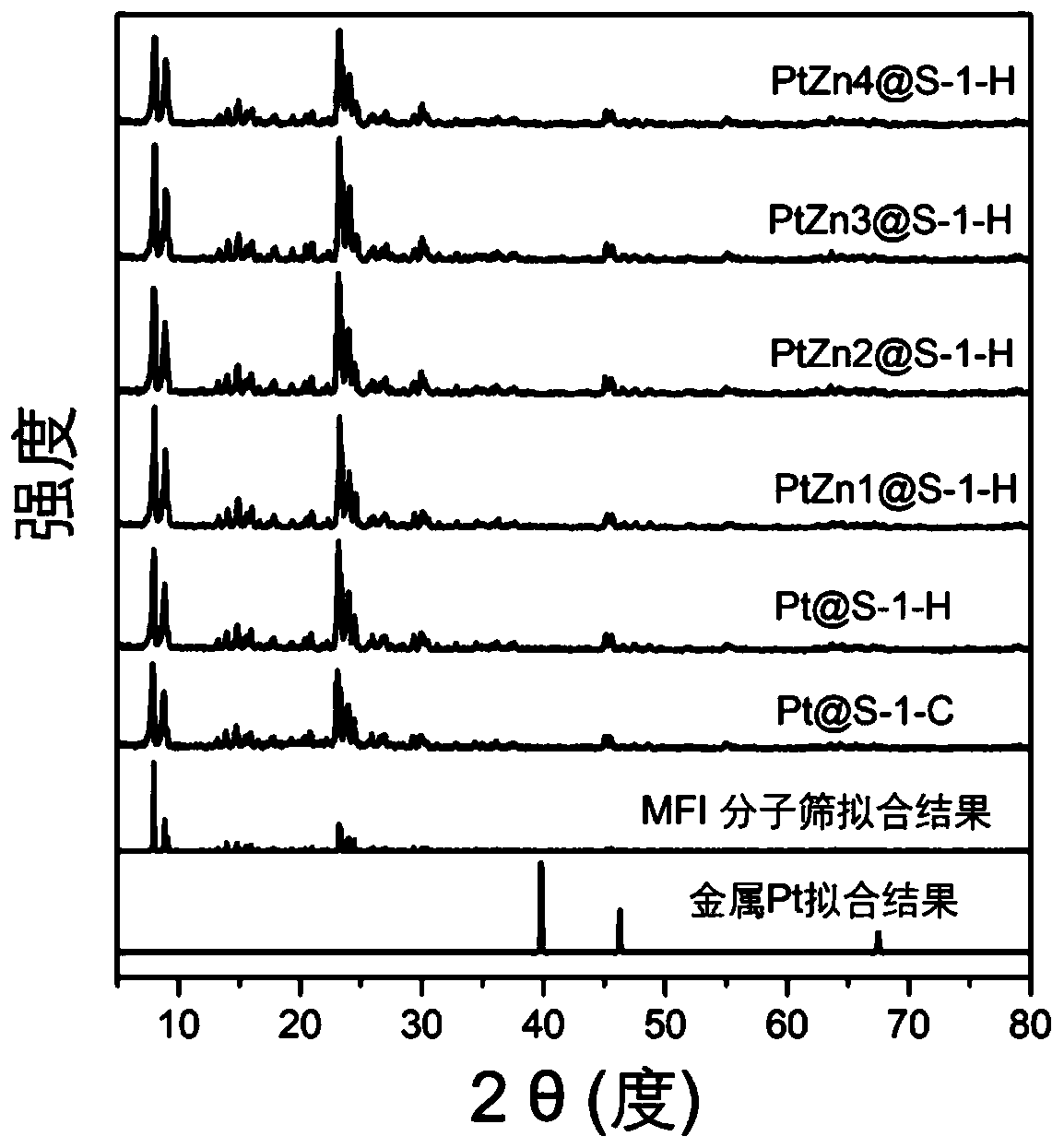

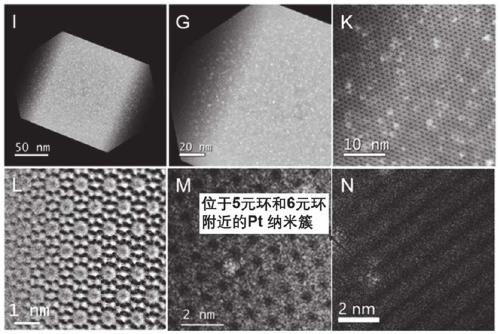

[0152] The synthesis ratio of PtZnx@S-1-H(x=0~4) catalyst is SiO 2 :TPAOH:H 2 O:A([Pt(NH 2 CH 2 CH 2 NH 2 ) 2 ]Cl 2 ):B([Zn(NH 2 CH 2 CH 2 NH 2 ) 3 ](OAc) 2 )=1:0.4:35:A:B (A=2.25×10 -3 , A / B=1 / 1, 1 / 2, 1 / 3, 1 / 4, without adding B and without adding A), the specific synthesis steps are as follows:

[0153] 1) Mix 13g TPAOH solution with 15g deionized water, stir at 25°C for 1 hour to dilute;

[0154] 2) 0.024g PtCl 2 Add to 0.15ml of ethylenediamine and water mixed solution (volume ratio of ethylenediamine and water is 0.15:1), stir at 60°C for 1 hour to PtCl 2 After complete dissolution, [Pt(NH 2 CH 2 CH 2 NH 2 ) 2 ]Cl 2 solution; 0.02g, 0.039g, 0.059g, 0.078g of zinc acetate dihydrate (corresponding to Pt / Zn molar ratios of 1 / 1, 1 / 2, 1 / 3 and 1 / 4, respectively) were added to 0.3ml of ethylene dihydrate In the mixed solution of amine and water (the volume ratio of ethylenediamine and water is 0.3:1), after stirring at 25°C for 1 hour, [Zn(NH 2 CH 2 CH 2 ...

Embodiment 2

[0166] The propane dehydrogenation reaction of the catalyst is carried out under the reaction pressure of 0.1MPa in a quartz tube fixed-bed reactor with an inner diameter of 20 mm. Before the dehydrogenation reaction, mix 0.3g of catalyst (25-40 mesh) with 1g of quartz sand, under the condition of reaction temperature of 550°C, in 10ml / min of H 2 Flow down and reduce for 1h, then add propane volume fraction and be the propane / nitrogen mixed gas of 25% to react, the flow of mixed gas is 40ml / min (C 3 h 8 / N 2 =10 / 30ml min -1 ). Among them, the PtZnx@S-1-H catalyst is the catalyst prepared in Example 1.

[0167] The catalytic reaction of propane dehydrogenation in Fig. 4 demonstrates that, Figure 4A is the conversion rate of propane on various catalysts; Figure 4B propylene selectivity on various catalysts; Figure 4C It is the long-term stability test results of PDH conversion on PtZn4@S-1-H and Pt@S-1-H catalysts. It can be seen from the figure that Pt@S-1-H has a hi...

Embodiment 3

[0186] In addition, the proportion of PtZn4@S-1-H catalyst synthesized by other raw materials is SiO 2 :TPAOH:H 2 O:([Pt(NH 2 CH 2 CH 2 NH 2 ) 2 ] 2+ ):([Zn(NH 2 CH 2 CH 2 NH 2 ) 3 ](NO 3 ) 2 )=1:0.25:30:4.5×10 -3 :1.8×10 -2 , the specific synthesis steps are as follows:

[0187] 1) Mix 8.1g of TPAOH solution with 13g of deionized water, and stir at 60°C for 0.5 hours to dilute;

[0188] 2) Add 0.093g of chloroplatinic acid hexahydrate to 0.3ml of a mixed solution of ethylenediamine and water (the volume ratio of ethylenediamine and water is 0.15:1), and stir at 25°C for 5 hours to obtain [ Pt(NH 2 CH 2 CH 2 NH 2 ) 2 ] 2+ solution; 0.21g of zinc nitrate hexahydrate was added to a mixed solution of 0.6ml of ethylenediamine and water (the volume ratio of ethylenediamine and water was 0.3:1), and after stirring for 1 hour at 60°C, [Zn (NH 2 CH 2 CH 2 NH 2 ) 2 ](NO 3 ) 2 solution.

[0189] 3) Add the complex solution obtained in step 2) to the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com