Non-fluorescence collapse-proof fluid loss additive for oil exploration drilling fluid

A fluid loss control agent and oil exploration technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of high cost, achieve low cost, reduce cost, and control water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A non-fluorescence anti-slump fluid loss agent for oil exploration drilling fluids, prepared from the following components: coal gangue 500Kg, waste acrylic fiber 270Kg, caustic soda NaOH 100Kg, formaldehyde 20Kg, sodium sulfite 30Kg, sodium bisulfite 30Kg, 50Kg of phenol, 3000Kg of water. The waste acrylic fiber yarn in the present invention is the discarded acrylic fiber yarn.

[0015] The method for preparing the above-mentioned non-fluorescent anti-slump fluid loss agent for oil exploration drilling fluid comprises the following steps:

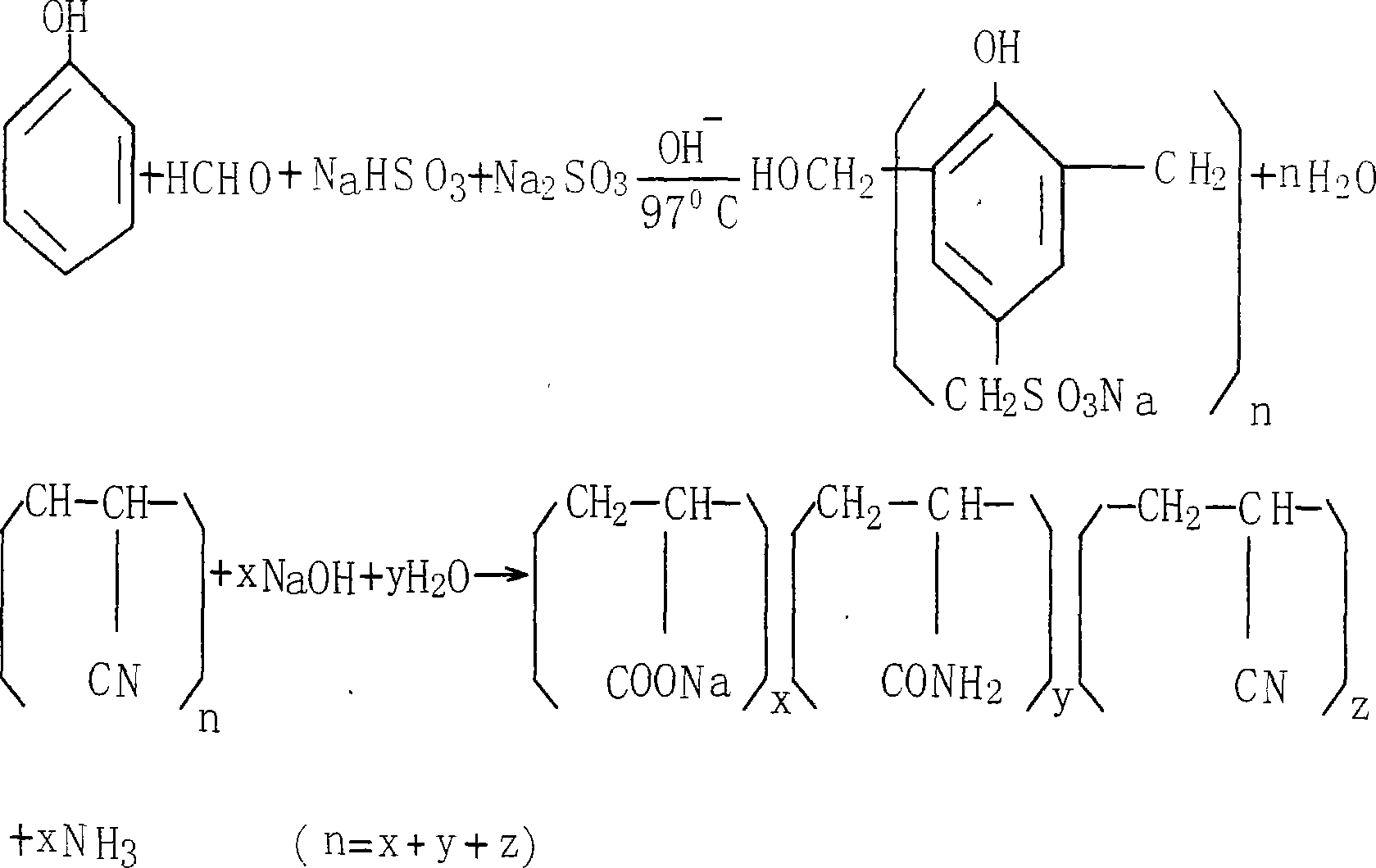

[0016] a, 50Kg of phenol, 20Kg of formaldehyde, 30Kg of sodium nitrite, 30Kg of sodium bisulfite and 1500Kg of water are fed at one time, and condensation and sulfonation reactions are carried out under the condition that the pH value is greater than 10 to generate sulfomethyl phenolic resin;

[0017] b. Hydrolyze polyacrylonitrile waste acrylic filaments at a pH value greater than 10, at a temperature of 110°C to 120°C and a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com