Amorphous nickel boron catalyst for hypnone hydrogenation and its preparation method

A catalyst, acetophenone technology, applied in the field of new amorphous catalyst and its preparation, can solve the problems of environmental pollution, low selectivity, large amount of waste aluminum lye and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

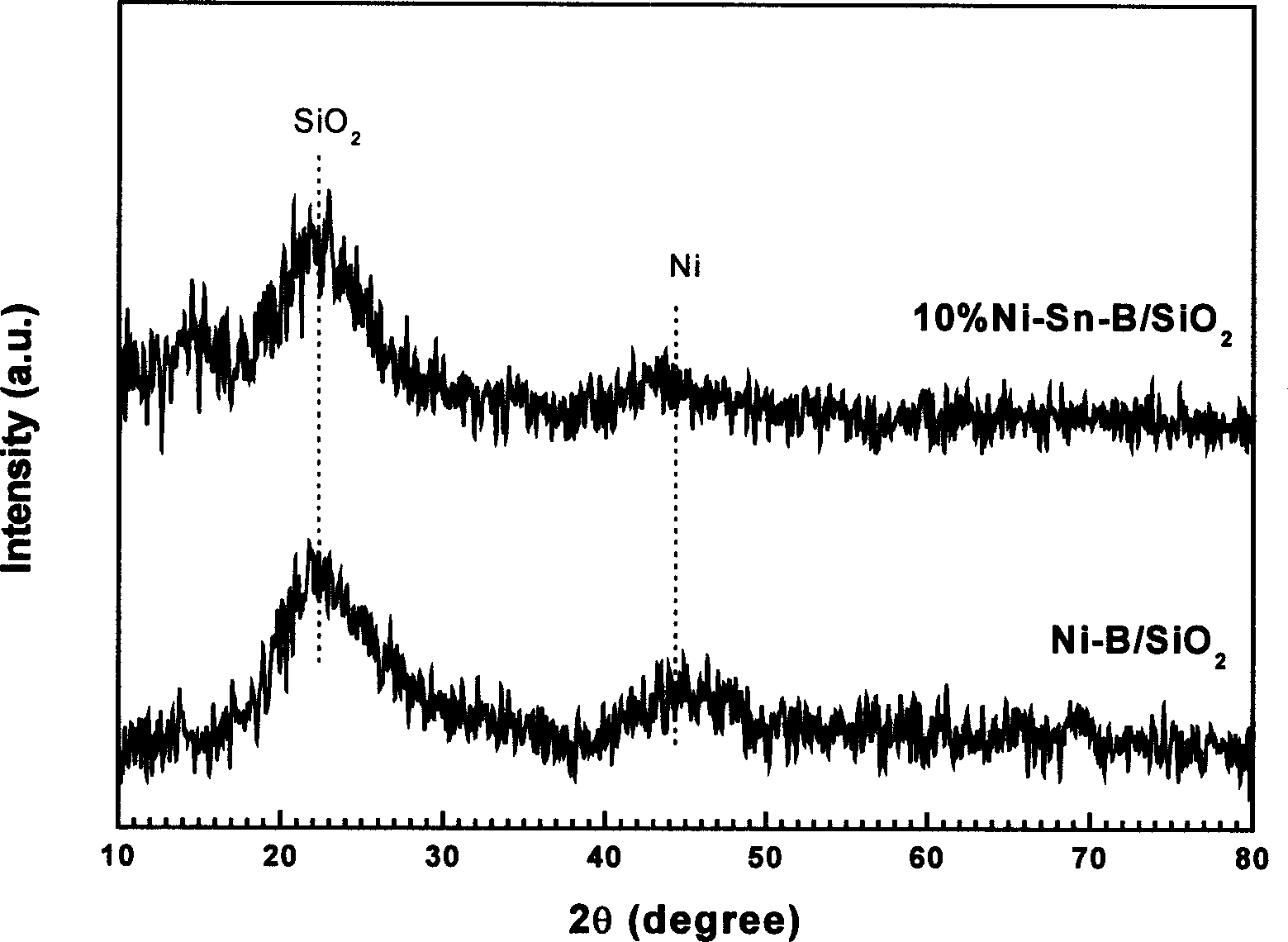

[0018] Embodiment 1: Preparation of supported Ni-B / L amorphous alloy catalyst

[0019] L carrier (select SiO 2 ) was boiled and washed with 0.5wt.% dilute nitric acid for 1 hour before use, then dried overnight under an infrared lamp at 110°C, and then roasted in a muffle furnace at 450°C for 3 hours, and after grinding, screened 40-60 meshes for catalyst preparation. With a certain concentration of NiCl 2 The carrier was impregnated with the solution, dried in an oven at 110°C overnight, and then calcined in a muffle furnace at 200°C for 2h. After cooling to room temperature, 2.0M KBH 4 The solution is slowly dropped in, and the molar ratio is B / Ni=4 / 1. After the dropwise addition, wash with distilled water until the pH value is about 7.0, and then wash with absolute ethanol several times. The obtained catalyst is recorded as Ni-B / SiO 2 , and the characterization results are shown in Table 1.

Embodiment 2

[0020] Embodiment 2: Preparation of supported Ni-Sn-B / L amorphous alloy catalyst

[0021] L carrier (select SiO 2 ) is obtained by the processing method in Example 1. A certain weight of SnCl 2 Solid dissolved in a certain concentration and volume of NiCl 2 In the solution, impregnate the carrier with the obtained mixed solution, dry it in an oven at 110°C overnight, and then bake it in a muffle furnace at 200°C for 2h. After cooling to room temperature, 2.0M KBH 4 The solution is slowly dropped in, and the molar ratio is B / (Ni+Sn)=4 / 1. After the dropwise addition, wash with distilled water until the pH value is about 7.0, and then wash with absolute ethanol several times before use. NiCl2 The dosage remains the same, by changing the added SnCl 2 The amount of solids, Ni-Sn-B / SiO with different Sn content can be prepared 2 catalyst. The obtained catalyst is recorded as Ni-Sn-B / SiO 2 -1. Ni-Sn-B / SiO 2 -2. Ni-Sn-B / SiO 2 -3, etc., the characterization results are shown...

Embodiment 3

[0022] Embodiment 3: Preparation of supported Ni-La-B / L amorphous alloy catalyst

[0023] L carrier (select SiO 2 ) is obtained by the processing method in Example 1. A certain concentration and volume of NiCl 2 solution with a certain concentration of LaCl 3 The solutions are mixed, and the carrier is impregnated with the obtained mixed solution, and the preparation method is the same as in Example 2. NiCl 2 The dosage remains the same, by changing the added LaCl 3 The amount of solution, Ni-La-B / SiO with different La content can be prepared 2 catalyst. The obtained catalyst is recorded as Ni-La-B / SiO 2 -1. Ni-La-B / SiO 2 -2. Ni-La-B / SiO 2 -3, etc., the characterization results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com