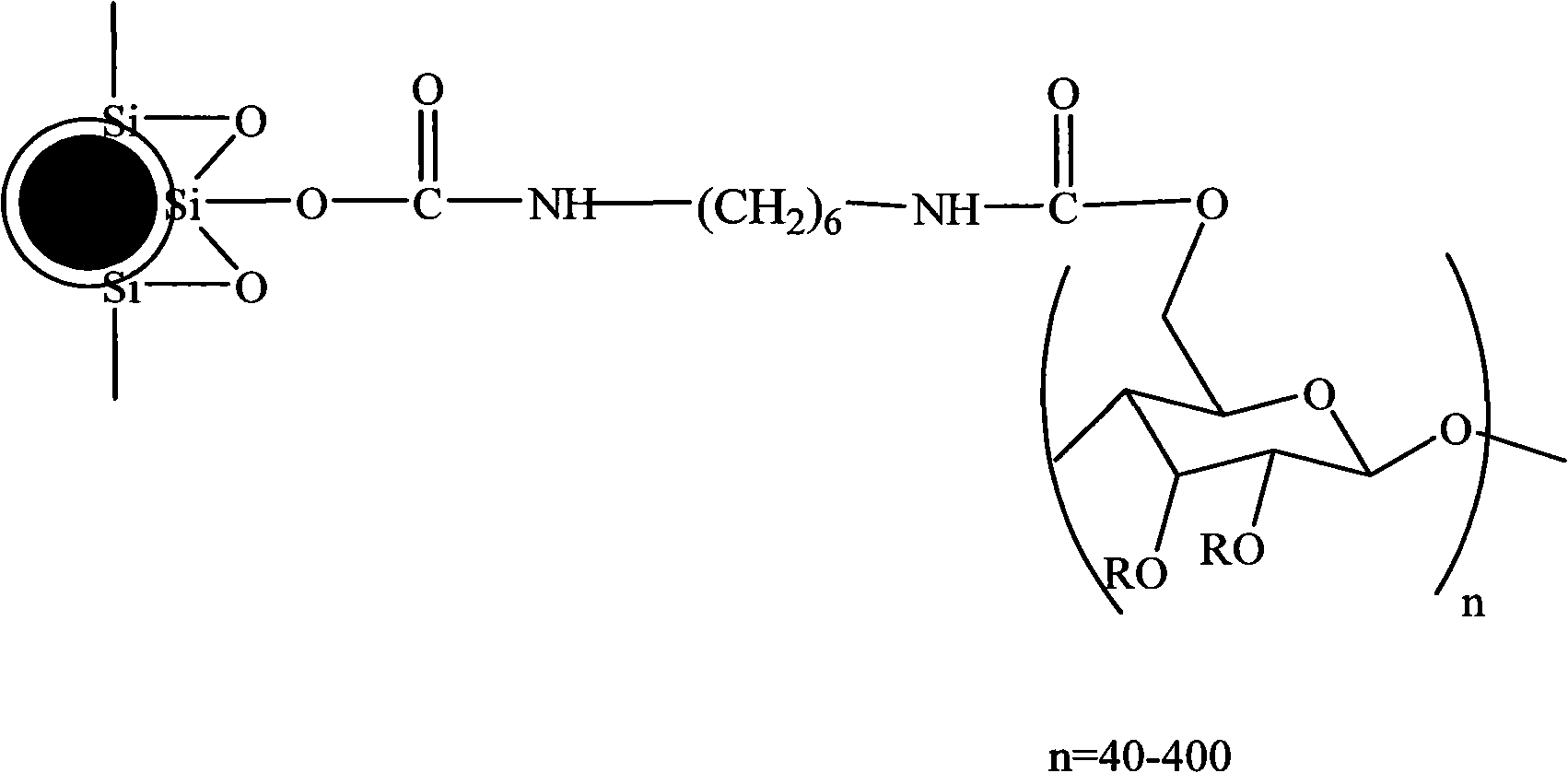

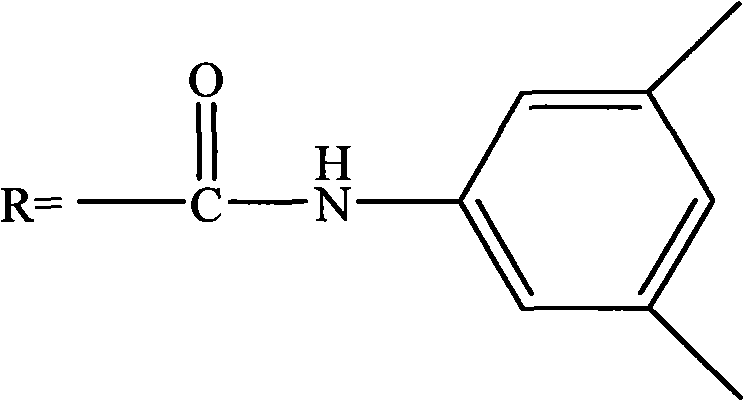

Chiral magnetic nano-particles and preparation and application thereof

A magnetic nanoparticle and nanoparticle technology, applied in chemical instruments and methods, organic racemization, organic chemistry, etc., to achieve the effects of good separation effect, simple and convenient operation, and short separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

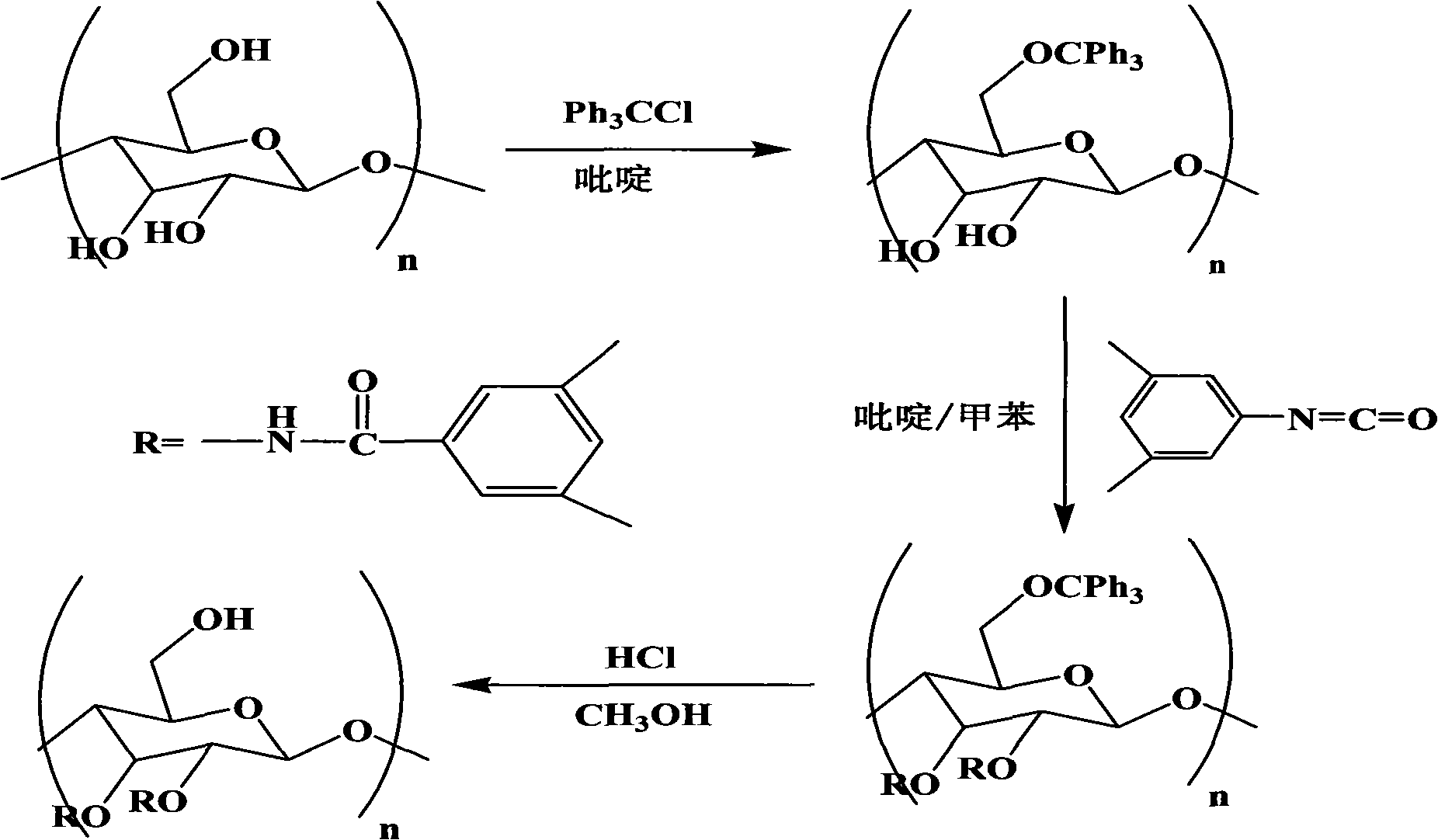

Method used

Image

Examples

Embodiment 1

[0023] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles: FeCl 3 .6H 2 O (2.0g) and FeCl 2 .4H 2 O (1.0g) is dissolved in water according to the amount of substance 1.5:1, pass through N 2 After 20 minutes, the temperature was raised to 60°C, and NH was added dropwise to the solution 3 .H 2 O to adjust pH=9, stop the reaction after 0.5h of heat preservation reaction, transfer the reaction mixture to a centrifuge tube for centrifugation, wash with deionized water until pH=7, vacuum dry at 60°C and grind to obtain the product Fe 3 o 4 stand-by;

[0024] (2) Fe 3 o 4 / SiO 2 Preparation of composite magnetic nanoparticles: weighing the first step product Fe 3 o 4 1g, add H 2 O and EtOH (1:1, v / v) 60ml ultrasonic dispersion 10min, pass N 2 , add NH under stirring 3 .H 2 O to adjust the pH to 9, add 1ml TEOS to the solution after heating up, keep it warm for 8 hours, transfer the reaction mixture to a centrifuge tube for centrifugation, wash with deionized water an...

Embodiment 2

[0030] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles: FeCl 3 .6H 2 O (2.1g) and FeCl 2 .4H 2 O (1.0g) is dissolved in water according to the amount of substance 1.6:1, pass through N 2 After 30 minutes, the temperature was raised to 70°C, and NH was added dropwise to the solution 3 .H 2 O to adjust pH=9, stop the reaction after 0.5h of heat preservation reaction, transfer the reaction mixture to a centrifuge tube for centrifugation, wash with deionized water until pH=7, vacuum dry at 70°C and grind to obtain the product Fe 3 o 4 stand-by;

[0031] (2) Fe 3 o 4 / SiO 2 Preparation of composite magnetic nanoparticles: weighing the first step product Fe 3 o 4 1g, add H 2 O and EtOH (1:1, v / v) 80ml ultrasonic dispersion 20min, pass N 2 , add NH under stirring 3 .H 2 O to adjust the pH to 9, add 1ml TEOS to the solution after heating up, keep it warm for 9 hours, transfer the reaction mixture to a centrifuge tube for centrifugation, wash with deionized water an...

Embodiment 3

[0037] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles: FeCl 3 .6H 2 O (2.4g) and FeCl 2 .4H 2 O (1.0g) is dissolved in water according to the amount of substance 1.75:1, pass through N 2 After 30 minutes, the temperature was raised to 70°C, and NH was added dropwise to the solution 3 .H 2 O to adjust pH=9, stop the reaction after 0.5h of heat preservation reaction, transfer the reaction mixture to a centrifuge tube for centrifugation, wash with deionized water until pH=7, vacuum dry at 60°C and grind to obtain the product Fe 3 o 4 stand-by;

[0038] (2) Fe 3 o 4 / SiO 2 Preparation of composite magnetic nanoparticles: weighing the first step product Fe 3 o 4 1g, add H 2 O and EtOH (1:2, v / v) 60ml ultrasonic dispersion 30min, pass N 2 , add NH under stirring 3 .H 2 Adjust O to pH=9, add 1.5ml TEOS to the solution after heating up, keep warm for 8 hours, transfer the reaction mixture to a centrifuge tube for centrifugation, wash with deionized water and EtOH,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com