Cement concrete accelerator

A cement concrete and quick-setting agent technology, applied in the chemical industry, can solve the problems of slow setting, large amount of quick-setting agent, and easy weathering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

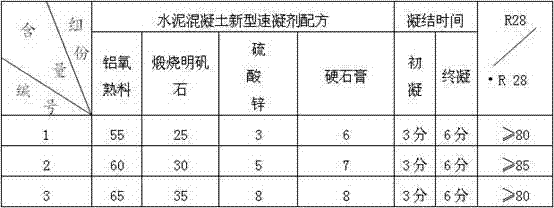

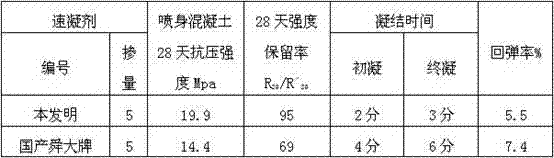

[0009] The present invention aims at the problems existing in the production and use of several existing quick-setting agents, and proposes a new cement concrete quick-setting agent formula, and through experimental verification, it is indeed proved that its technical and economic indicators are faster than the existing concrete quick-setting agent. The coagulant is advanced.

[0010] The cement concrete quick-setting agent of the present invention is based on the alumina clinker of the existing production plant; the alumina clinker is made of limestone, bauxite, and soda ash in a certain proportion, and is formed by grinding and calcining. As a known technology in the industry, alumina clinker is indispensable for the rapid setting of cement, but when considering its dosage, it should be reduced as much as possible on the premise of ensuring that the required setting time is achieved and at the same time it has good weathering resistance In order to minimize the reduction in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com