Composite premix feed for laying hen and processing technique thereof

A compound premix and premix technology, applied in animal feed, animal feed, food processing, etc., can solve the problems of raw material separation, high feed-to-egg ratio, low egg production rate, etc., and achieve egg yolk with natural red color and nutritious Balanced richness and high egg production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

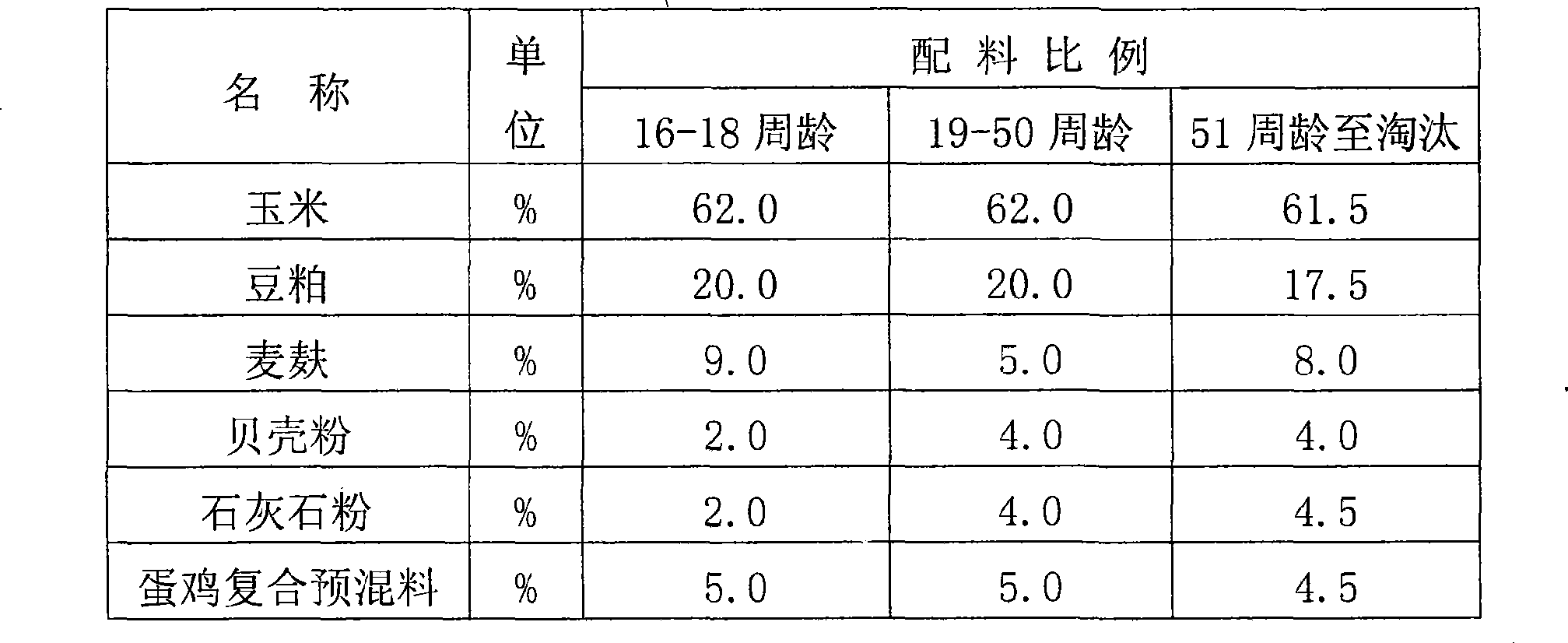

Method used

Image

Examples

Embodiment 1

[0027] Example 1, a composite premix for laying hens includes raw materials in the following weight ratios: 3 kg of manganese sulfate, 3 kg of zinc sulfate, 3 kg of ferrous sulfate, 0.6 kg of copper sulfate, 12 kg of choline chloride, 7 kg of lysine, and methionine 26kg, 1.6kg of phytase, 400kg of calcium carbonate, 80kg of calcium hydrogen phosphate, 300kg of fish meal, 45kg of salt and multidimensional layer;

[0028] Among them, multi-dimensional laying hens include:

[0029] Vitamin A 0.20kg, Vitamin D 3 0.06kg, vitamin E 0.52kg, vitamin K 3 0.047kg, vitamin B 1 0.026kg, vitamin B 2 0.177kg, vitamin B 6 0.078kg, Vitamin B 12 0.025kg, folic acid 0.02kg, biotin 0.008kg, niacin 0.3kg, calcium pantothenate 0.11kg and rice husk powder 1.2kg.

[0030] The above composite premix is produced according to the following process:

[0031] 1) Pretreatment: cleaning and pulverizing the raw materials weighed according to the ratio;

[0032] 2) Premixing: place the pretrea...

Embodiment 2

[0049]Example 2, a composite premix for laying hens includes raw materials in the following weight ratios: 6kg of manganese sulfate, 5kg of zinc sulfate, 5kg of ferrous sulfate, 1kg of copper sulfate, 15kg of choline chloride, 9kg of lysine, and 30kg of methionine , phytase 2kg, calcium carbonate 430.5kg, calcium hydrogen phosphate 100kg, fish meal 330kg, salt 60kg and layer multidimensional;

[0050] Among them, the layer multivitamin includes: vitamin A 0.38kg, vitamin D 3 0.12kg, vitamin E 0.962kg, vitamin K 3 0.088kg, vitamin B 1 0.048kg, Vitamin B 2 0.206kg, Vitamin B 6 0.091kg, Vitamin B 12 0.05kg, folic acid 0.023kg, biotin 0.016kg, niacin 0.578kg, calcium pantothenate 0.21kg and rice husk powder 3.27kg.

[0051] The above composite premix is produced according to the following process:

[0052] 1) Pretreatment: cleaning and pulverizing the raw materials weighed according to the ratio;

[0053] 2) Premixing: place the pretreated manganese sulfate, zinc sul...

Embodiment 3

[0070] Embodiment 3, a kind of laying hen compound premix comprises the raw material of following weight ratio:

[0071] Manganese sulfate 9kg, zinc sulfate 7kg, ferrous sulfate 7kg, copper sulfate 1.4kg, choline chloride 18kg, lysine 11kg, methionine 34kg, phytase 2.4kg, calcium carbonate 461kg, calcium hydrogen phosphate 120kg, fish meal 360kg, 75kg of salt and multi-dimensional layers;

[0072] Among them, multi-dimensional laying hens include:

[0073] Vitamin A 0.44kg, Vitamin D 3 0.14kg, Vitamin E 1.12kg, Vitamin K 3 0.1kg, vitamin B 1 0.056kg, Vitamin B 2 0.33kg, Vitamin B 6 0.145kg, Vitamin B 12 0.058kg, folic acid 0.03kg, biotin 0.018kg, niacin 0.674kg, calcium pantothenate 0.245kg and rice husk powder 3.83kg.

[0074] The above composite premix is produced according to the following process:

[0075] 1) Pretreatment: cleaning and pulverizing the raw materials weighed according to the ratio;

[0076] 2) Premixing: place the pretreated manganese sulfate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com