Laundry detergent

A technology of laundry detergent and composition, applied in the field of laundry detergent, can solve the problems of inability to inhibit bacteria, cross-infection of bacteria, etc., and achieve the effects of improving cleaning function, avoiding cross-infection, and improving cleaning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

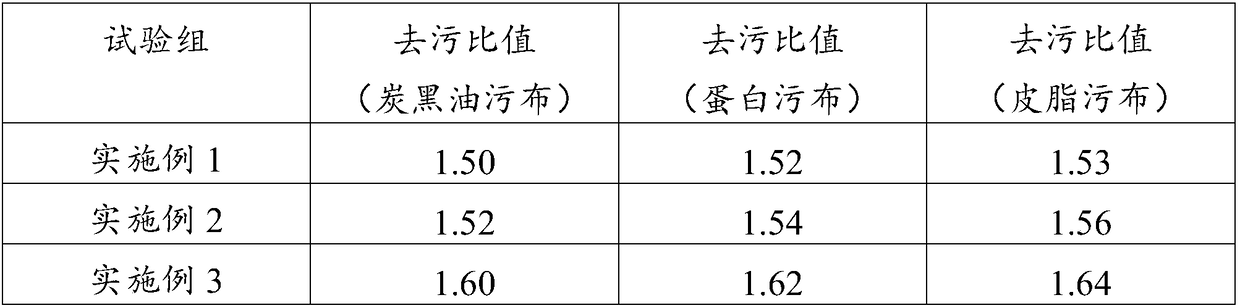

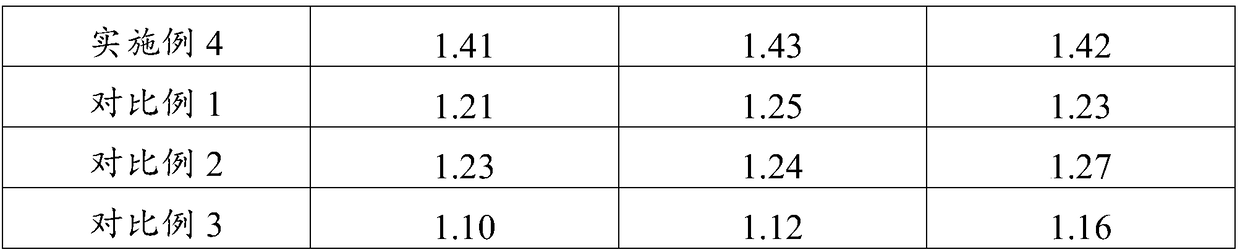

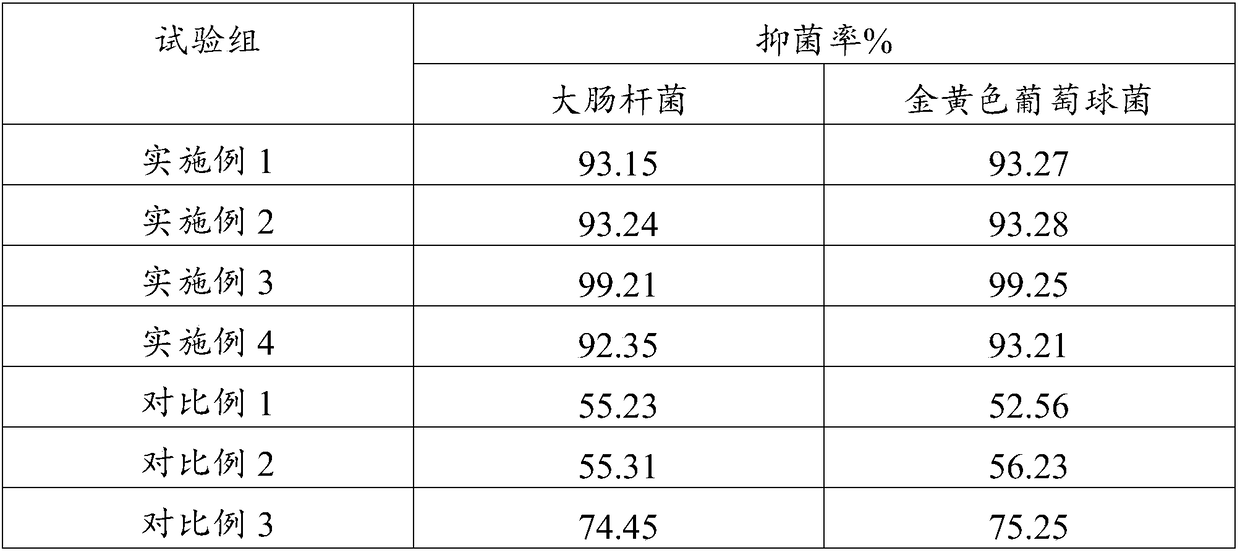

Examples

preparation example Construction

[0044] The present invention also provides a preparation method of laundry detergent, which is used for preparing the above laundry detergent. The preparation method comprises the following steps:

[0045] Add deionized water into the reactor in parts by mass, then add anionic surfactant, nonionic surfactant, and co-solvent into the reactor, and stir at a temperature of 50-60°C; wait until the raw materials are completely dissolved and After mixing evenly, lower the temperature to 30-40°C, then add chitosan and organosilicon quaternary ammonium salt into the reaction kettle, and continue stirring for 10 minutes; then add cellulase and protease, stir evenly and filter to obtain laundry detergent.

[0046]Wherein, the mass parts of the above-mentioned main components are as follows: 5-10 parts of anionic surfactant; 10-20 parts of nonionic surfactant; 0.5-2.0 parts of cellulase; 0.5-2.0 parts of protease; 0.01-1.5 parts of enzyme stabilizer 0.1-1.0 parts of organic silicon qua...

Embodiment 1

[0049] A laundry detergent, comprising: 5 parts by weight of anionic surfactant; 10 parts of nonionic surfactant; 0.5 part of cellulase; 0.5 part of protease; 0.01 part of enzyme stabilizer; 1.0 part of organic silicon quaternary ammonium salt ; 0.1 part of chitosan; 2.0 parts of co-solvent; 30 parts of deionized water.

[0050] Wherein, the anionic surfactant is fatty alcohol polyoxyethylene ether sodium sulfate, the nonionic surfactant is fatty alcohol polyoxyethylene ether, the enzyme stabilizer is calcium chloride and sodium citrate, and the organic The silicon quaternary ammonium salt is 3-(trimethoxysilyl)propyloctadecyldimethylammonium chloride.

[0051] The preparation method of the laundry detergent: add deionized water into the reaction kettle according to the mass fraction, then add anionic surfactant, nonionic surfactant and co-solvent into the reaction kettle, and stir at a temperature of 50-60°C ;After the raw materials are completely dissolved and mixed evenly,...

Embodiment 2

[0053] A laundry detergent, comprising: 8.0 parts of anionic surfactant; 15 parts of nonionic surfactant; 1.0 part of cellulase; 1.0 part of protease; 0.1 part of enzyme stabilizer; 0.1 part of organic silicon quaternary ammonium salt ; 1.0 parts of chitosan; 3.0 parts of co-solvent; 60 parts of deionized water.

[0054] Wherein, the anionic surfactant is fatty acid methyl ester ethoxylate sodium sulfonate, the nonionic surfactant is cardanol polyoxyethylene ether, and the enzyme stabilizer is calcium chloride and sodium citrate. The organosilicon quaternary ammonium salt is 3-(triethoxysilyl)propyloctadecyldimethylammonium chloride.

[0055] The preparation method of the laundry detergent: add deionized water into the reaction kettle according to the mass fraction, then add anionic surfactant, nonionic surfactant and co-solvent into the reaction kettle, and stir at a temperature of 50-60°C ;After the raw materials are completely dissolved and mixed evenly, lower the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com