Machine tool equipped with cutting fluid filtering device

A filtration device and cutting fluid technology, which is applied in filtration and separation, fixed filter element filters, manufacturing tools, etc., can solve the problems of unconsidered, ineffective use of compressed air pressure, insufficient effect, etc., to improve the effect of backwashing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

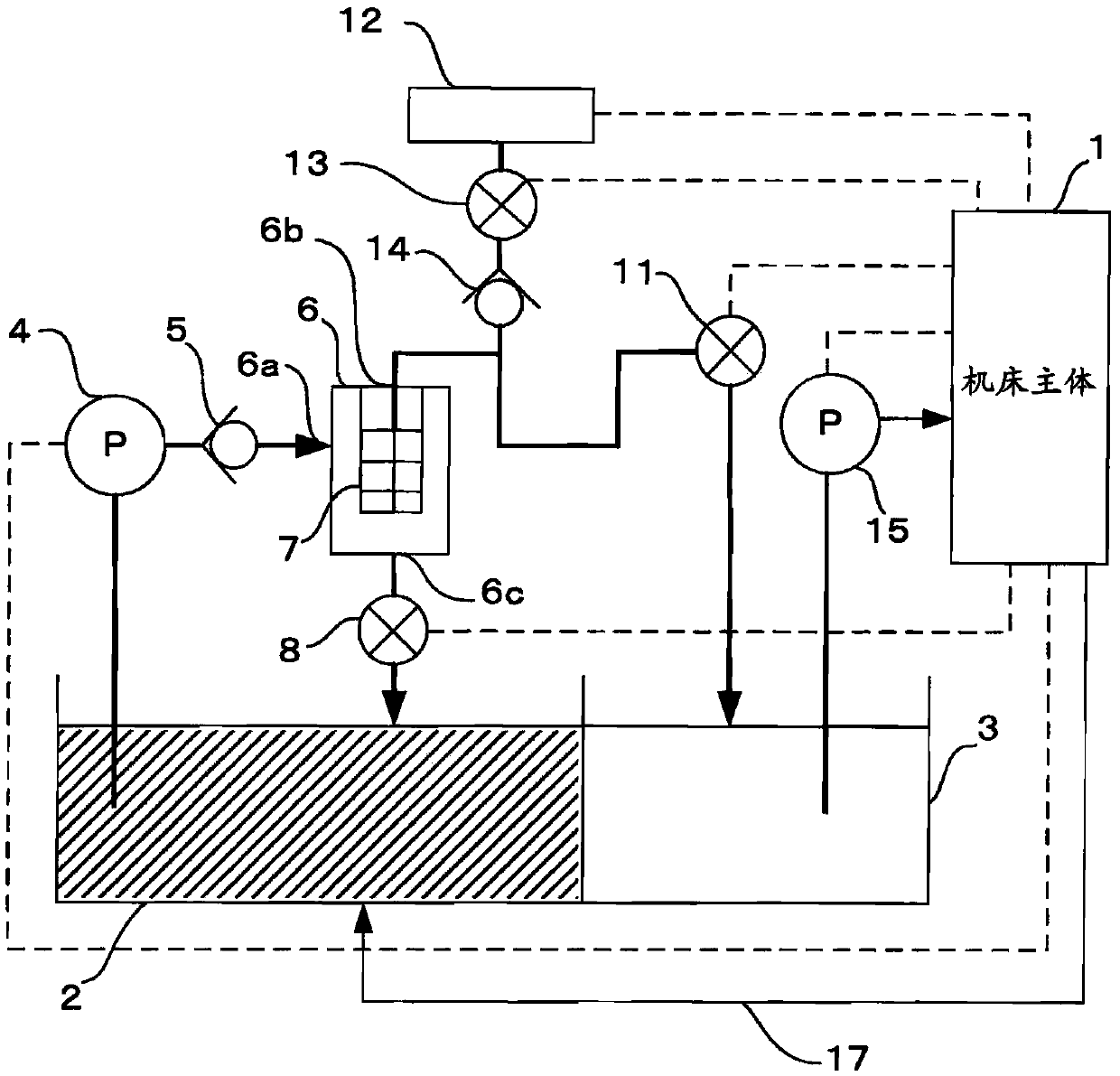

[0031] First, use figure 1 A first embodiment of the cutting fluid filter device will be described.

[0032] Symbol 1 is the main body of the machine tool with the control device, 2 is the sewage tank, 3 is the clean water tank, 4 is the filter pump, 5 is the check valve installed behind the filter pump when viewed from the flow direction of the cutting fluid, and 6 is the filter pump. container. The filter container 6 is provided with an inflow port 6a for the cutting fluid from the filter pump 4, an opening 6b through which the cutting fluid flows out during filtering and air flows during backwashing, and an opening 6b through which air or cutting fluid is discharged during backwashing. The discharge port 6c is provided with a filter 7 inside the filter container 6 . In addition, reference numeral 8 is a backwash discharge valve, 11 is a clean water tank valve, 12 is an air source, 13 is an air supply pump, and 14 is a check valve installed on the downstream side of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com