Double-side polishing device and method capable of controlling rigidity of polishing pad through cluster dynamic magnetic field

A dynamic magnetic field and double-sided polishing technology, which is applied in the direction of grinding drive devices, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems of inconsistent relative speed and uneven processing of workpieces, and achieve good consistency and low cost. The effect of low cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

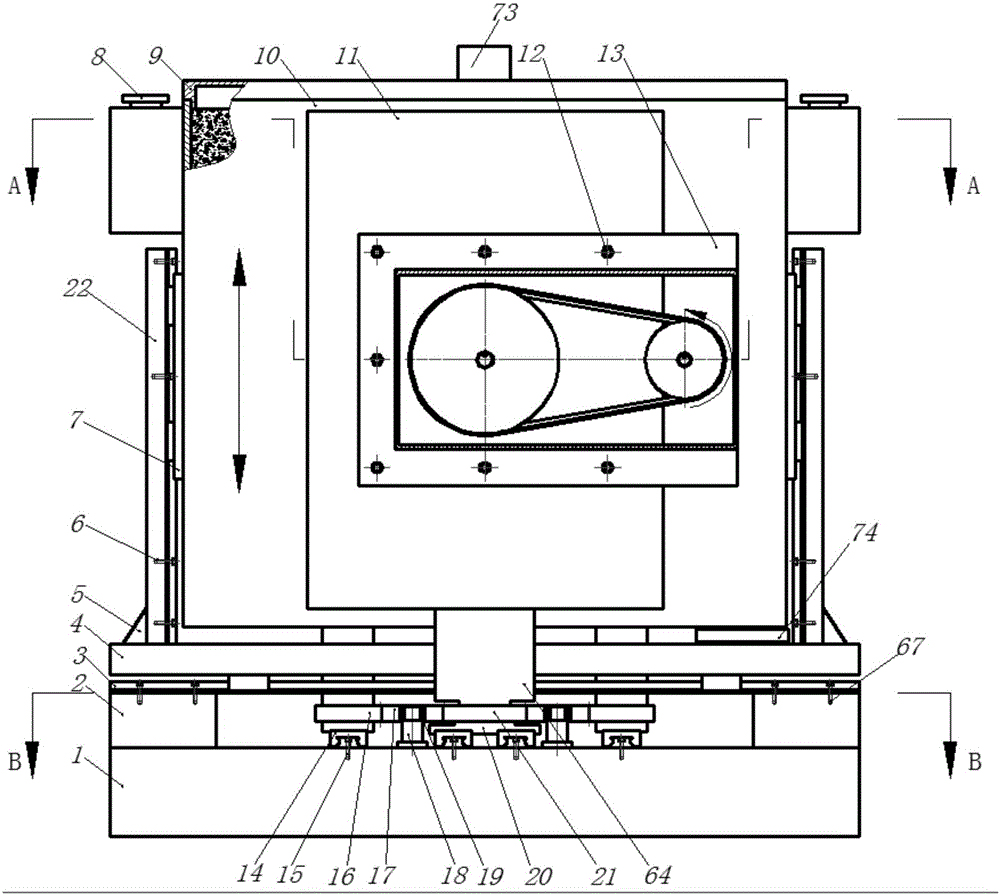

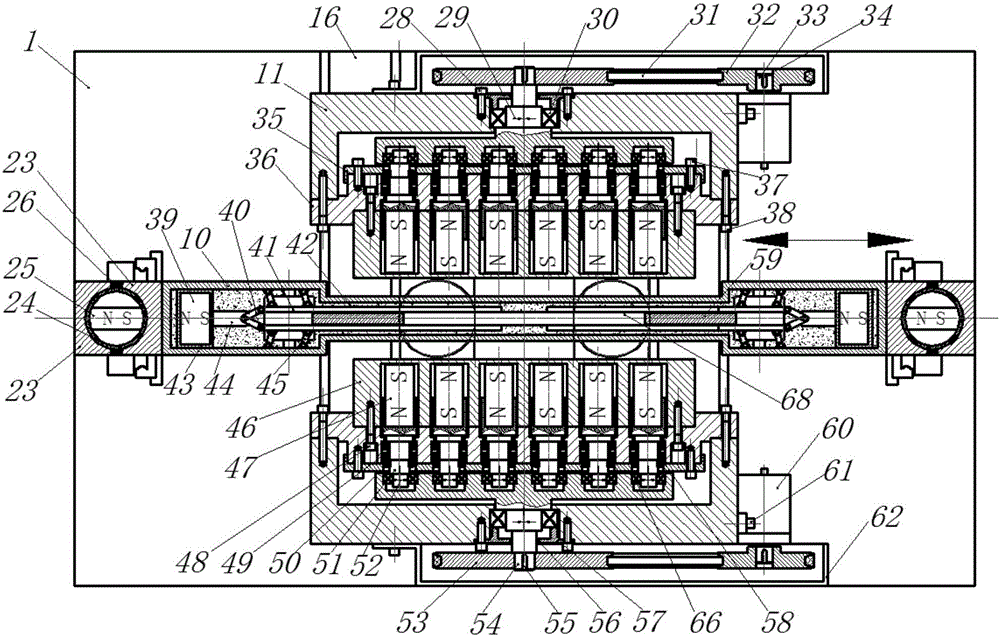

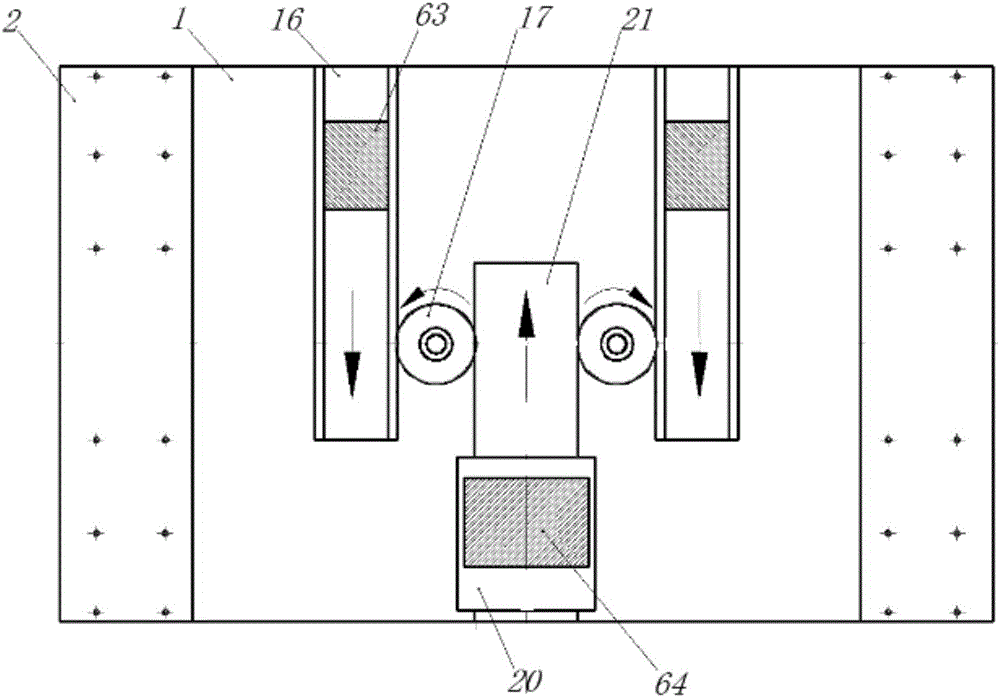

[0046] Such as figure 1 with figure 2 As shown, a double-sided polishing device for controlling the stiffness of a polishing pad by a cluster dynamic magnetic field is characterized in that it includes a variable stiffness cluster magnetron polishing pad generating mechanism, a workpiece fast clamping mechanism and a workpiece motion drive mechanism, and the variable stiffness cluster magnetron The polishing pad generating mechanism includes base (1), screw two (12), linear guide rail (14), screw three (15), precision single-sided rack (16), gear (17), gear shaft (18), deep Groove bearing (19), precision double-sided rack (21), connecting plate one (63), connecting plate two (64), grooved end cover (9), housing (11), screw four (28), main shaft Eccentric distance (29), rolling bearing (30), V-shaped belt (31), small pulley (32), motor shaft (33), small flat key (34), bearing cover plate (35), bearing seat plate (36) , screw five (37), screw six (38), magnet mount (46), cyli...

Embodiment 2

[0056] Using the polishing method of the double-sided polishing device using the cluster dynamic magnetic field to control the stiffness of the polishing pad, the steps of performing double-sided polishing pads on a square TFT-LCD glass substrate with a size of 100mm×100mm are as follows:

[0057] 1) According to the size and material properties of the TFT-LCD glass substrate, design a double-sided polishing device that matches the workpiece size with a cluster dynamic magnetic field to control the stiffness of the polishing pad. Magnet (47) is installed in the double-sided polishing device of cluster dynamic magnetic field control polishing pad rigidity, and rotating rotary handle (8) makes the magnetic pole direction of bar-shaped permanent magnet (25) and square magnet (39) vertical, prepares and workpiece shape and Circular cage with suitable thickness;

[0058] 2) According to the shape of the TFT-LCD glass substrate, use acid and alkali corrosion-resistant plastics to ma...

Embodiment 3

[0068] The difference between this embodiment and Embodiment 2 is that this embodiment is to perform double-sided polishing on a single crystal silicon substrate with a diameter of 100mm, and the polishing method of the double-sided polishing device for controlling the stiffness of the polishing pad by a cluster dynamic magnetic field of the present invention includes the following step:

[0069] 1) According to the size and material properties of the single crystal silicon substrate, design a double-sided polishing device that matches the size of the workpiece with a cluster dynamic magnetic field to control the stiffness of the polishing pad. Magnet (47) is installed in the double-sided polishing device of cluster dynamic magnetic field control polishing pad rigidity, and rotating rotary handle (8) makes the magnetic pole direction of bar-shaped permanent magnet (25) and square magnet (39) vertical, prepares and workpiece shape and Circular cage with suitable thickness;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com