Aromatic olefin-reducing catalyst and use thereof

An olefin catalyst and catalyst technology, which is applied in molecular sieve catalysts, physical/chemical process catalysts, refining with metal salts, etc., can solve the problems of short clay life, frequent replacement, and high labor intensity, so as to prolong life and reduce carbon deposition rate , Improve the effect of anti-carbon deposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

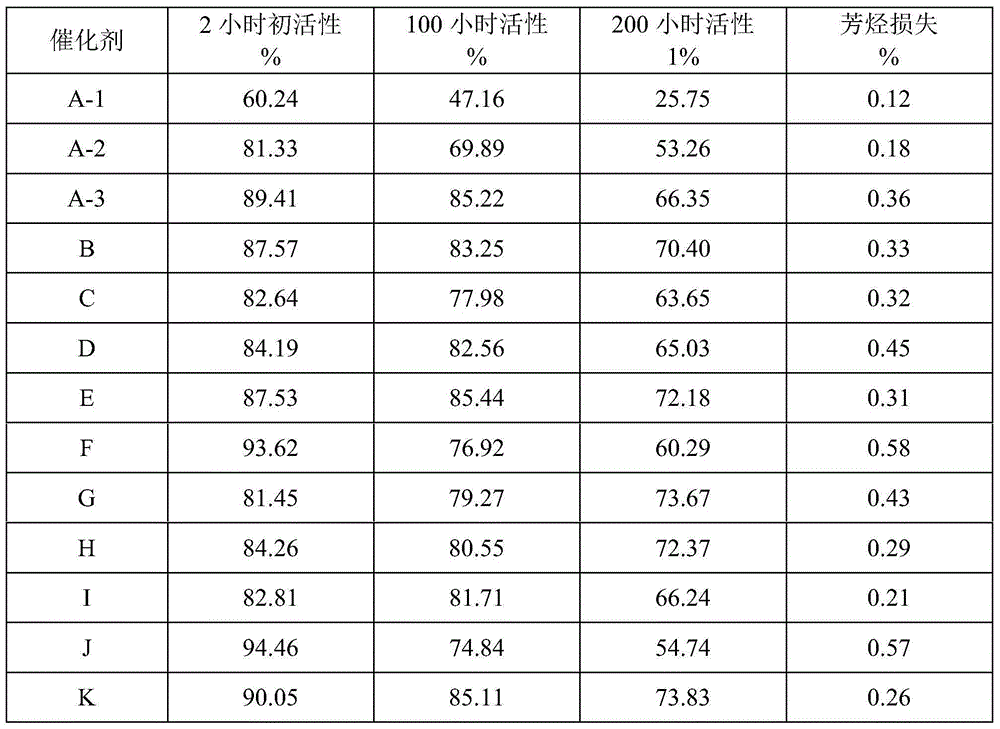

Embodiment 1

[0024] Take Na 2 Pseudo-boehmite (α-Al) with an O content of less than 0.15% (weight) and a loss on ignition of 30% at 550°C 2 o 3 ·H 2 O) 128.57 grams, with Na 2 11.10 grams of mordenite with an O content of less than 1.5% (weight) and a loss on ignition of 10% were mixed evenly, and a solution was prepared with 2.5 milliliters of chemically pure nitric acid and 65 milliliters of water. Add this mixed solution to the mixture of pseudo-boehmite and mordenite, mix evenly, knead and extrude into a rod, dry it and bake it at 550°C for 3 hours to obtain the catalyst A- 1.

Embodiment 2~3

[0026] Using the preparation method of Example 1, adjusting the ratio of molecular sieve and pseudo-boehmite, respectively prepared catalyst A-2 with alumina:molecular sieve=50:50 and catalyst A-3 with alumina:molecular sieve=10:90.

Embodiment 4~10

[0028] Replace the mordenite used in A-2 with beta zeolite, X zeolite, Y zeolite, ZSM-5 molecular sieve, SAPO-11 molecular sieve, MCM-41 molecular sieve, TS molecular sieve, and prepare B, C, D, E, F, G, H catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com