Patents

Literature

30 results about "Normal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low resistance generally refers to 1.8 Ohms-2.4 Ohms, the normal resistance refers to 2.8-3.2 Ohms, and High resistance refers 4.0+ Ohms.

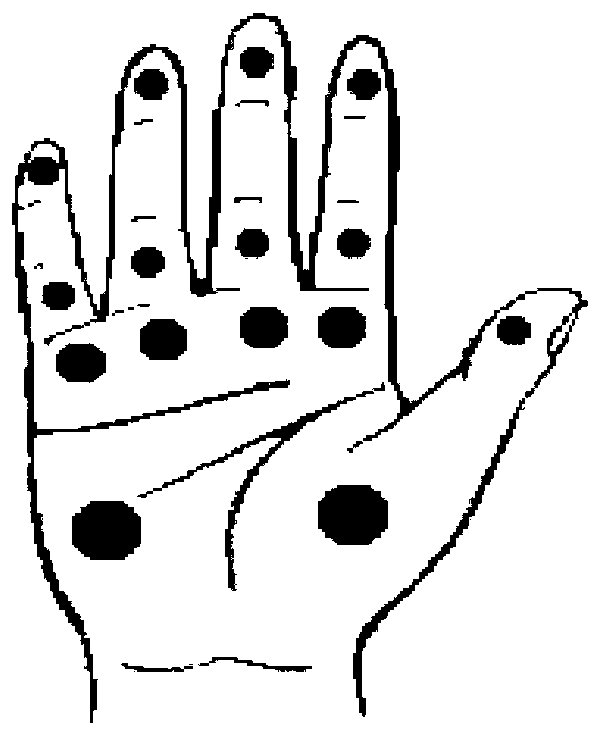

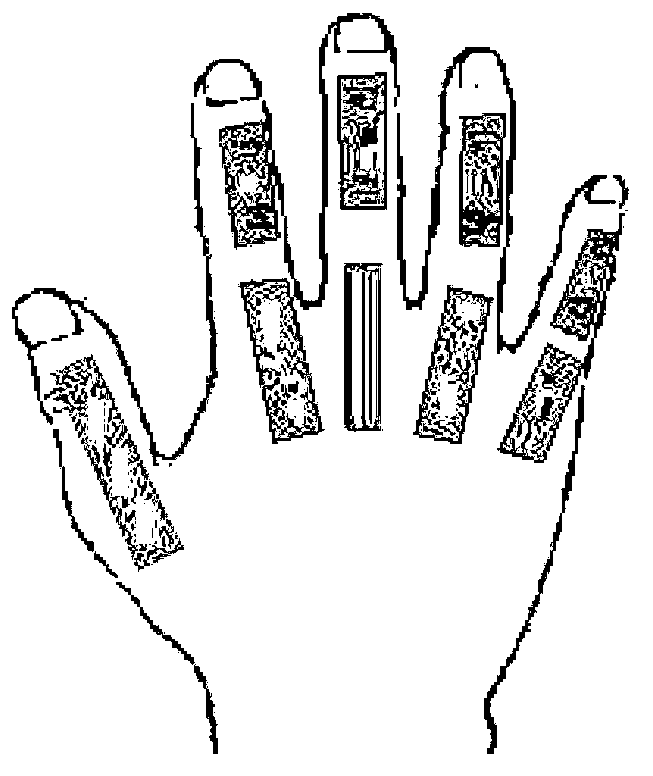

Data gloves for function rehabilitation training and assessment of hands and monitoring method thereof

InactiveCN103251419AReactivityReflect resistanceDiagnostic recording/measuringSensorsNormal resistanceMuscle force

The invention discloses data gloves for function rehabilitation training and assessment of hands. Each data glove further comprises bent sensor groups which are arranged on the hand back side inside the each data glove in a packaged mode and flexible pressure sensor groups which are arranged on the palm side inside each data glove. The bent sensor groups are placed on finger joints, the pressure sensor groups are placed on the a plurality of key nodes where a hand is in contact with an object when the object is grabbed, and lead-out lines of the bent sensor groups and lead-out lines of the pressure sensor groups are packaged inside each data glove, collected to the outer side of a forearm via the hand back side, and connected with a subsequent hardware processing circuit. The data gloves for the function rehabilitation training and the assessment of the hands are strong in wearability and capable of collecting finger bending angle information and palm pressure information of the hands of a patient, the finger bending angle information and the palm pressure information are used in the hand function rehabilitation training under a virtual environment, and quantitative assessment results of a muscle force range from no joint movement to movement capable of resisting normal resistance can be given.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU +2

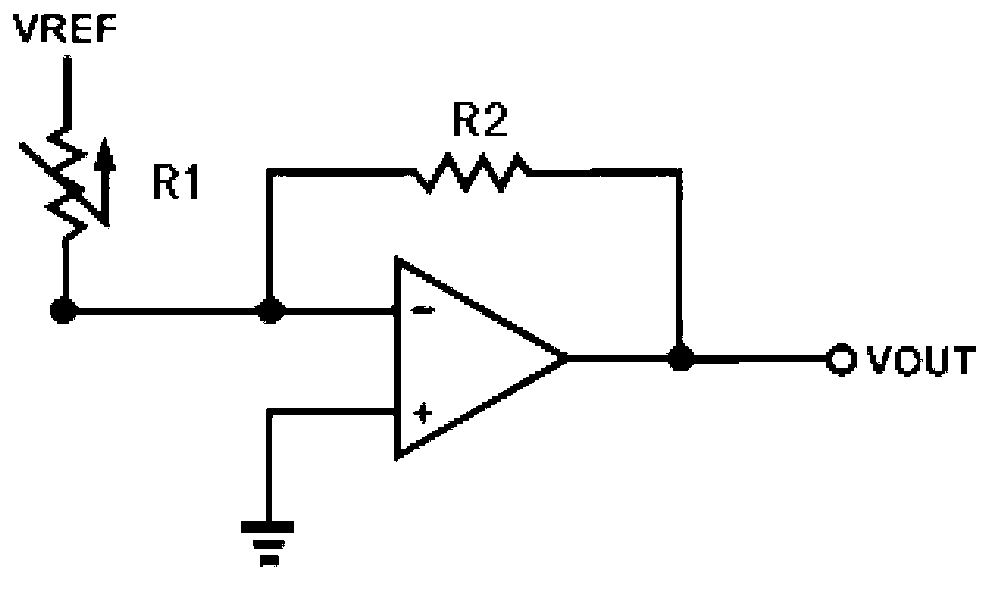

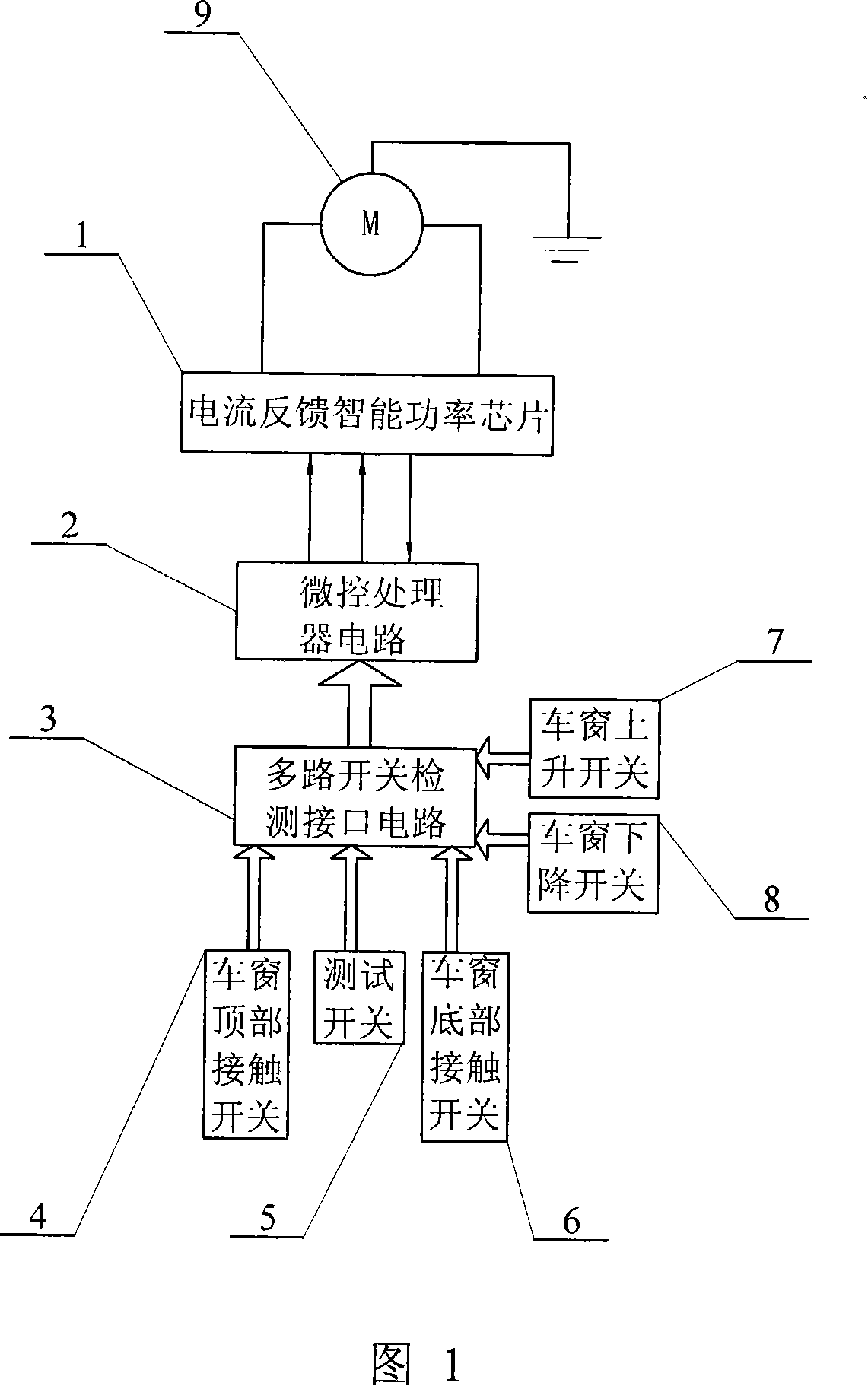

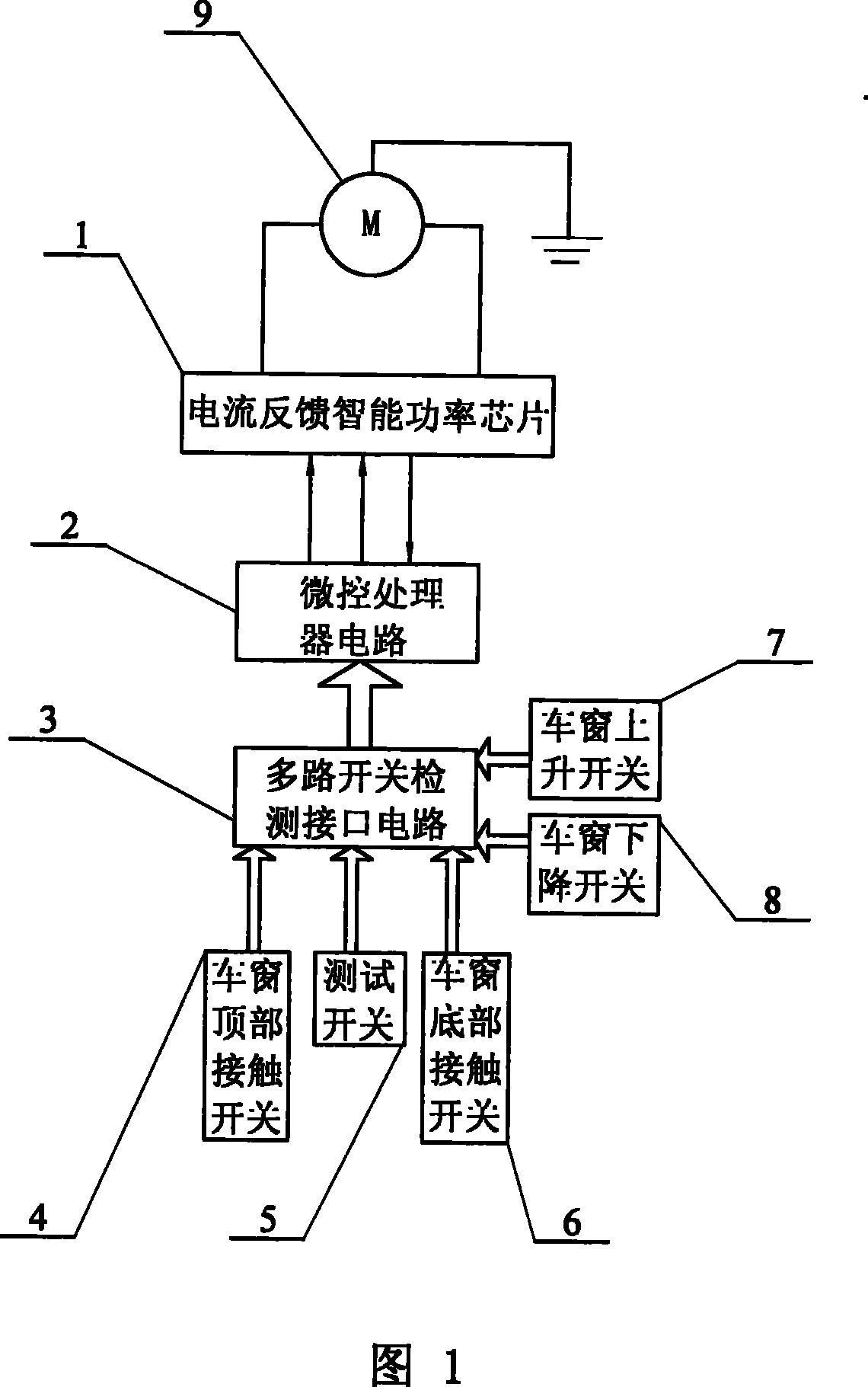

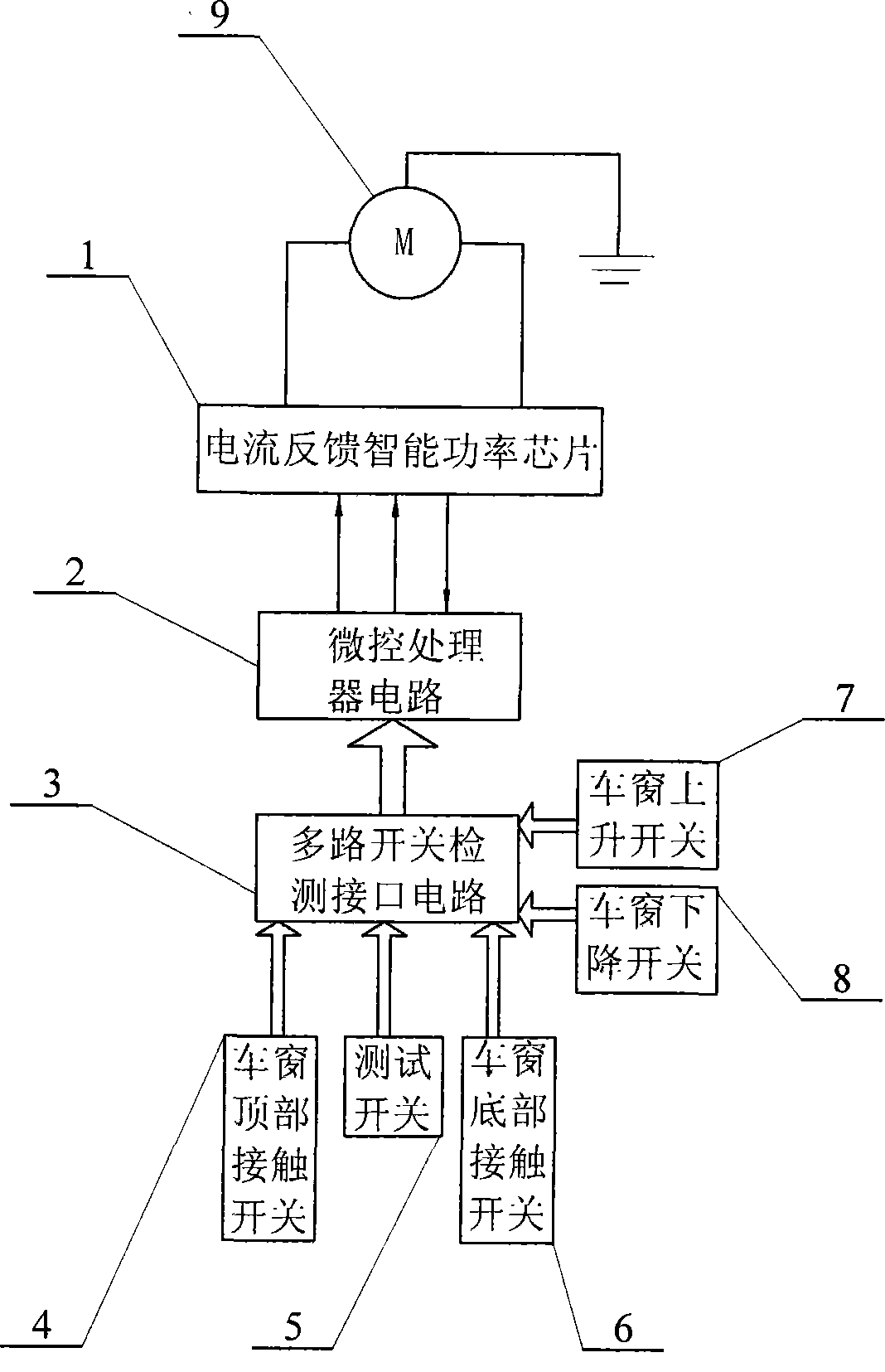

Vehicle window drive clamping-proof control system and control method thereof

InactiveCN101148965AHigh anti-pinch precisionStable jobWindowsWindscreensMultiway switchingNormal resistance

The present invention is squeeze preventing automobile window driving system and control method, and relates to squeeze preventing automobile window driving technology. The system includes one microprocessor circuit, one intelligent feedback power chip, one multiway switch detection interface circuit, one window top touch switch, one test switch, one window bottom touch switch, one window ascent switch and one window descent switch connected together. The control method includes the following steps: for the microprocessor circuit to detect braking current value for N times and normal resistance current value for N times and to store the calculated threshold value in a flash memory; to compare with the reference current value in the flash memory, and to rotate the motor inversely to execute the squeeze preventing function if the calculated threshold value is greater. The present invention has high precision and capacity of updating the reference current value.

Owner:HARBIN INST OF TECH

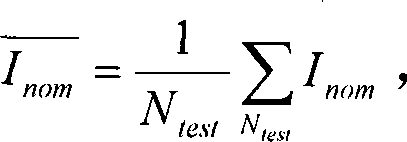

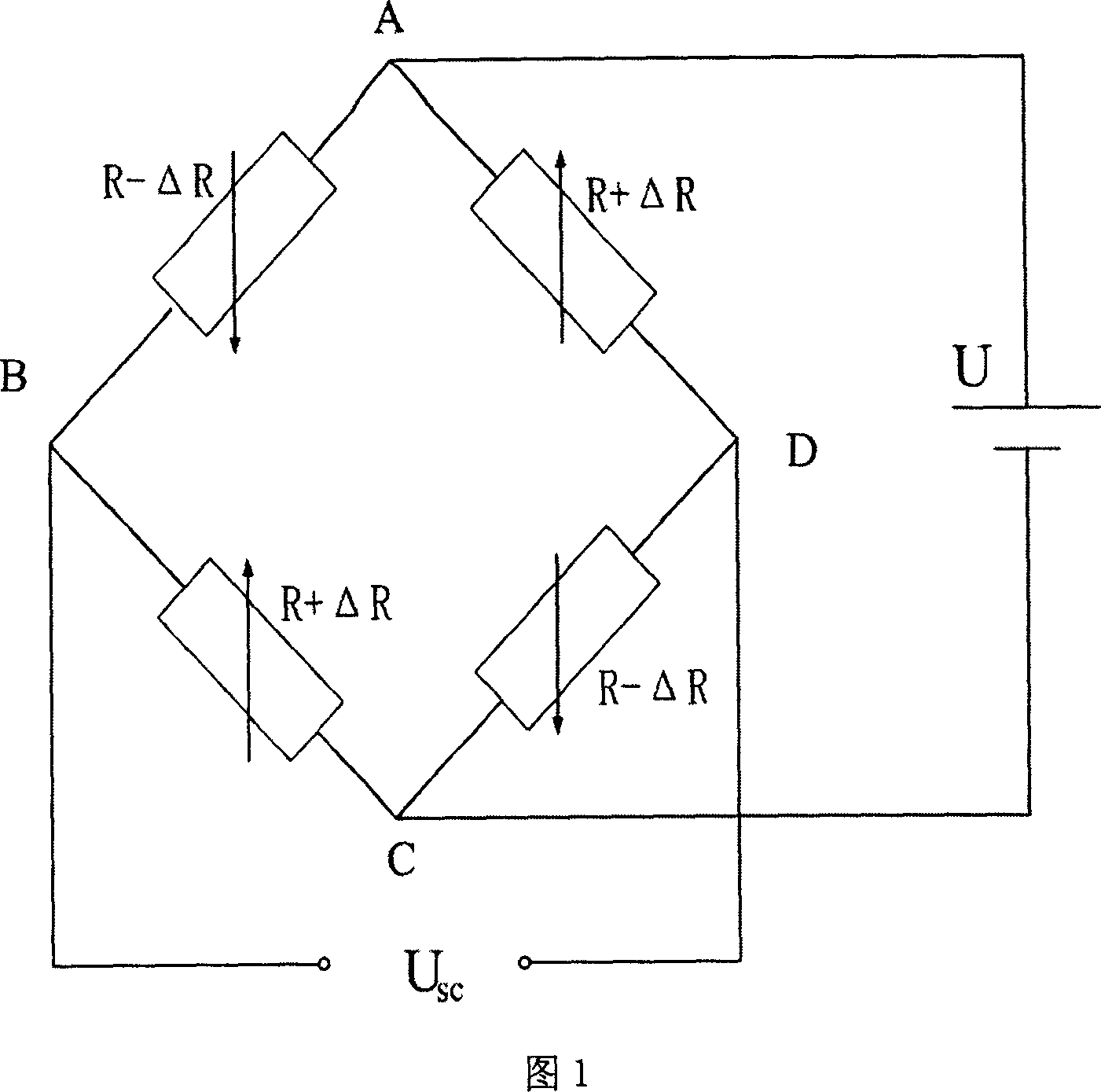

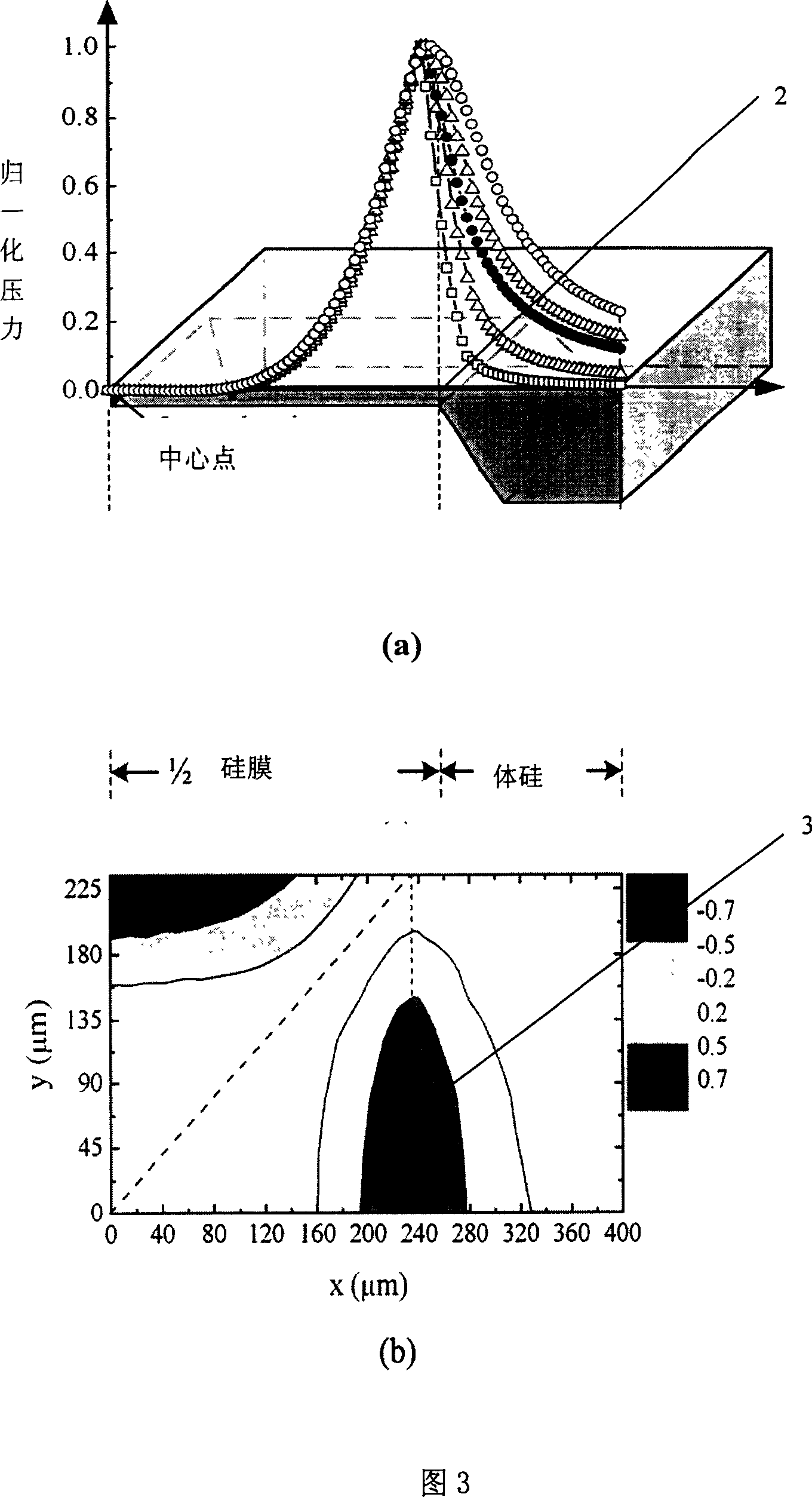

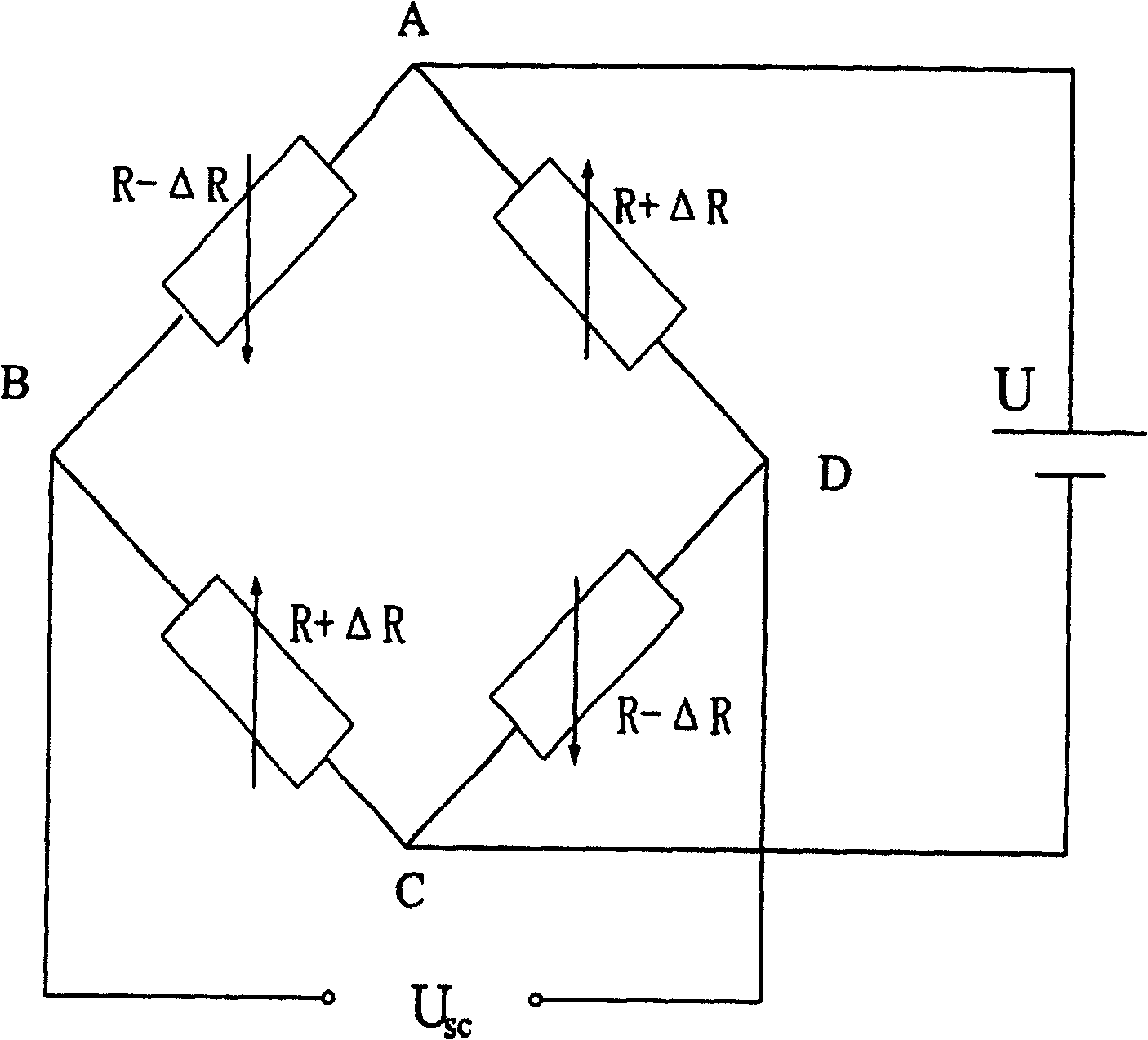

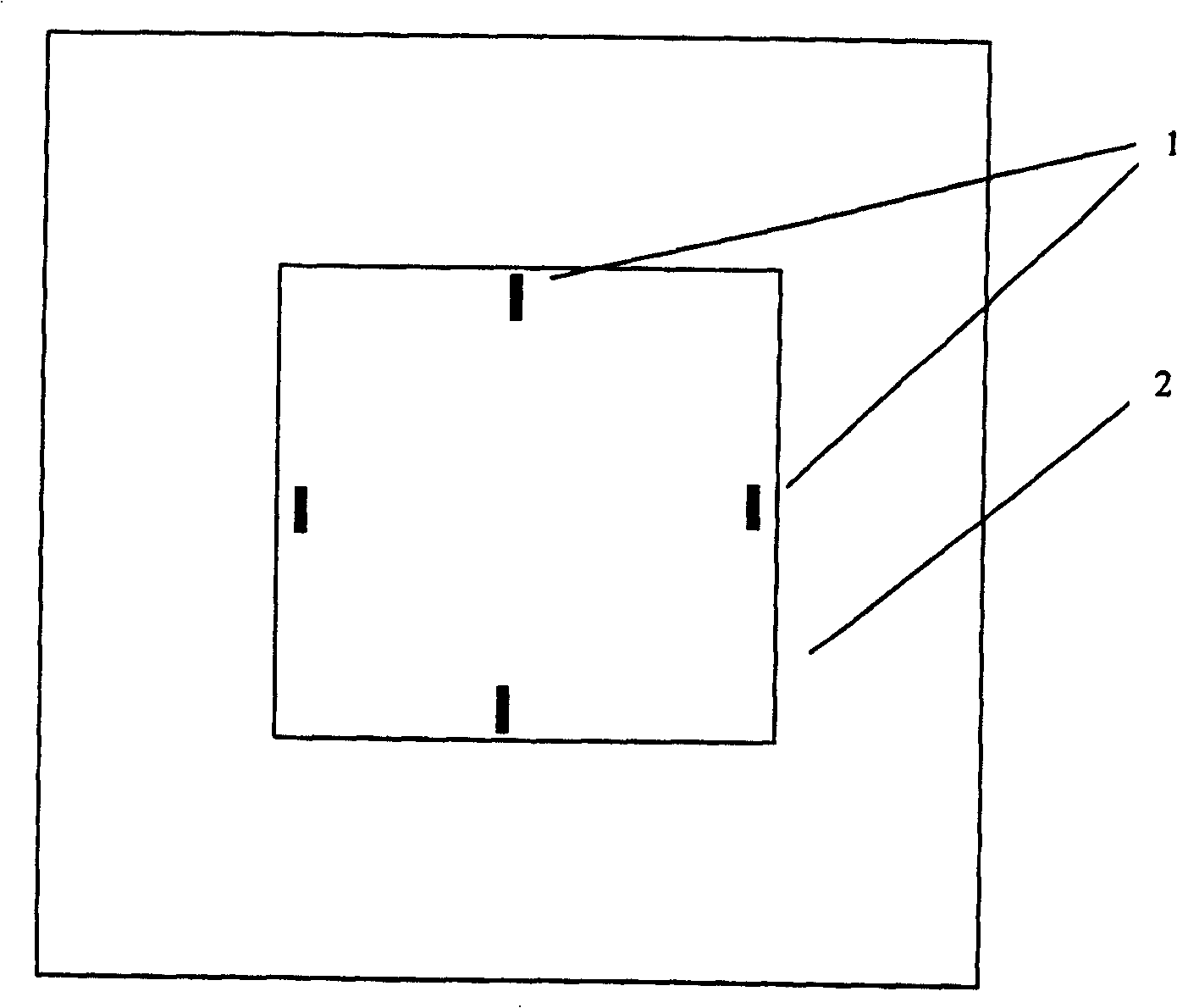

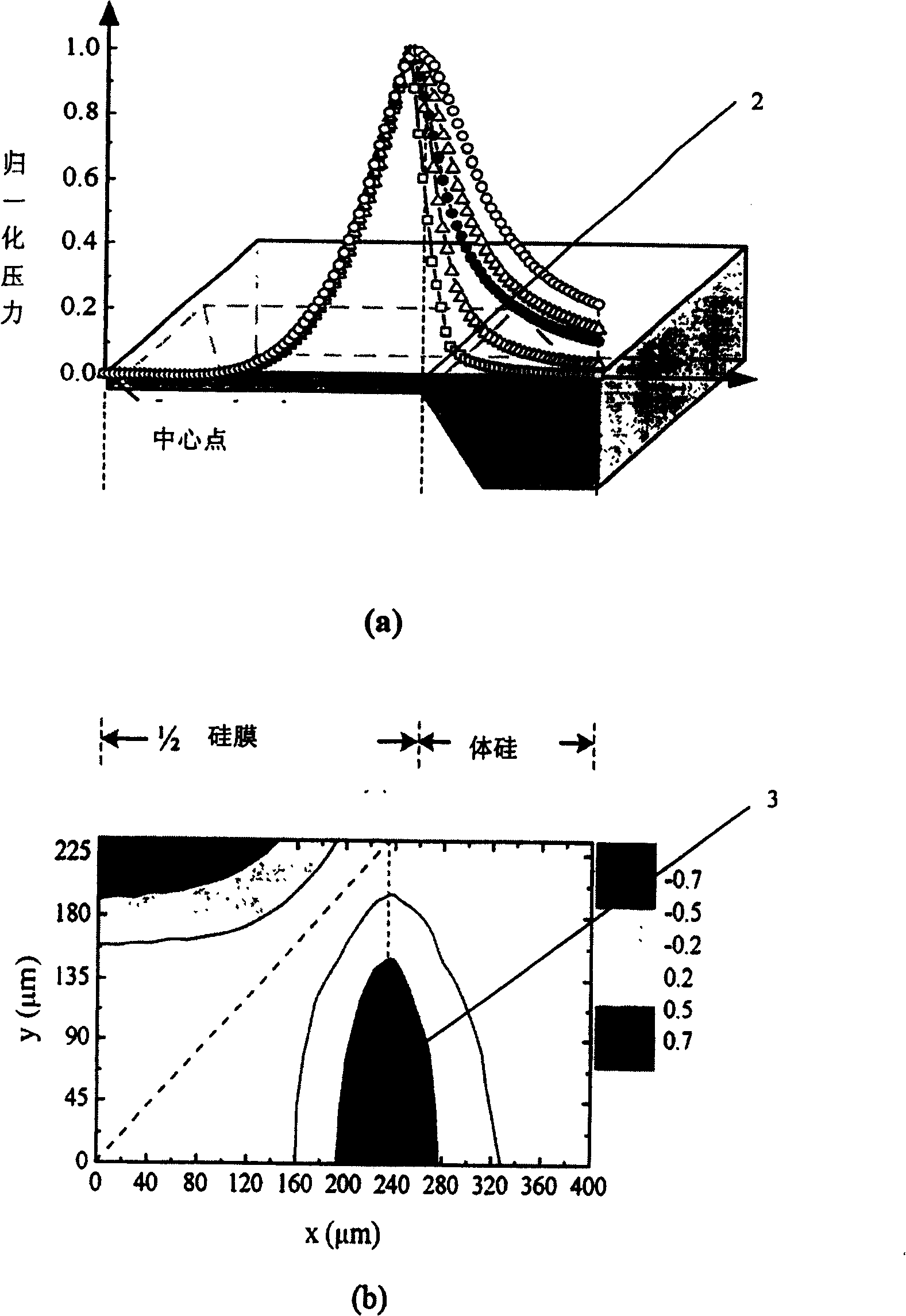

Wide stress area silicon pressure sensor

InactiveCN101034021AHigh sensitivityForce measurement using piezo-resistive materialsHigh concentrationPressure sense

This invention belongs to semiconductor pressure sensor technosphere. The sensor includes pressure-sensing film that stressed zone stretched and supporting part around it. voltage dependent resistance lay in high-stress area that cross over pressure-sensing film, compose Wheatstone bridge, to convert pressure change to electrical signal; broken number of the described voltage dependent resistance perpendicular to pressure-sensing film's bound is greater than that parallel to pressure-sensing film bound, to meet shape of high stress region; resistance strip width of turnover section is greater than normal resistance strip width; processing ion implantation of high concentration at the same time to wane ohmic value of turnover section; the pressure-sensing film thickness-width ratio as far as possible large, to satisfy require of bound's high stress region width. The invention is at the condition of chip area reducing but line not reducing, utilize membrane outer region of high stress to increase stressed zone area, to advance sensor sensitivity and reduce numbers of rejects.

Owner:TSINGHUA UNIV

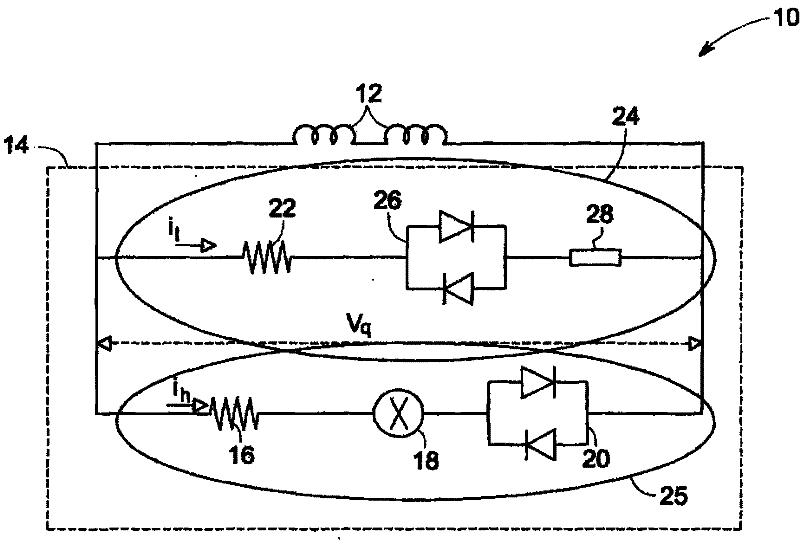

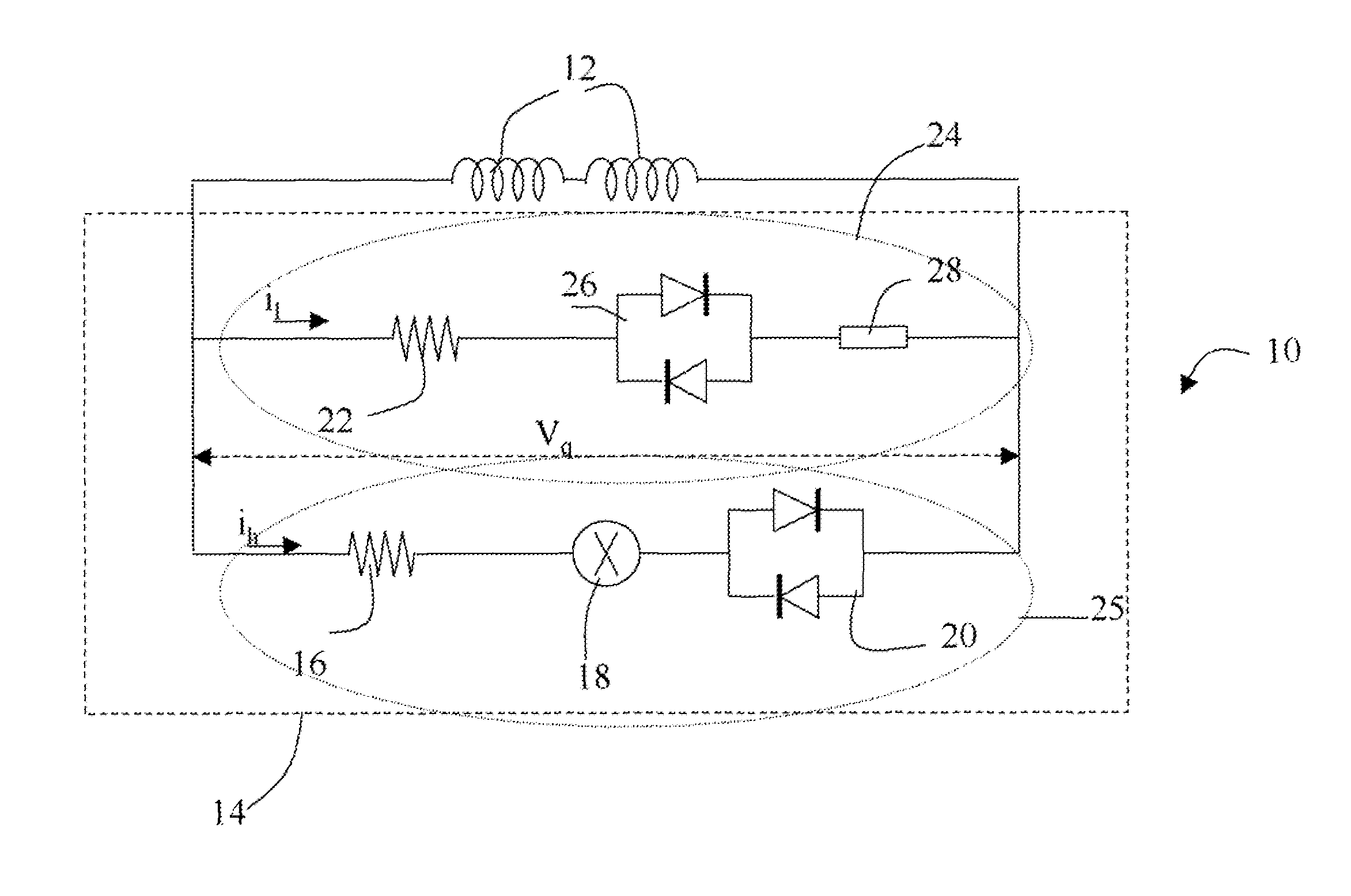

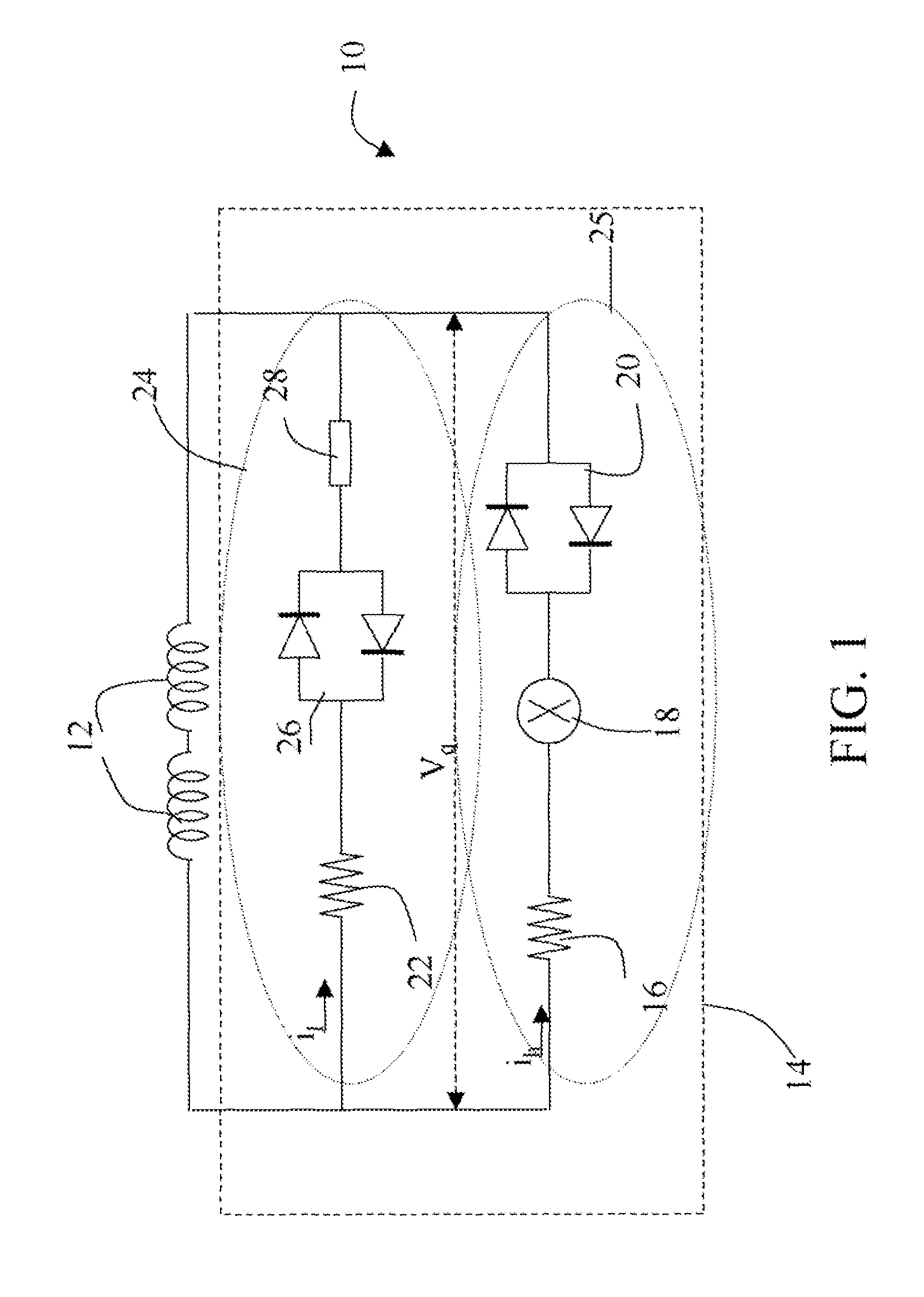

Superconducting magnet and superconducting magnet system

ActiveCN102412047AEmergency protective arrangements for automatic disconnectionSuperconducting magnets/coilsNormal resistanceSuperconducting Coils

The invention relates to a superconducting magnet and a superconducting magnet system. The superconducting magnet comprises a superconducting coil and a quenching protection circuit which is connected with the superconducting coil in parallel, wherein the quenchinging protection circuit comprises a quenching heater group which is in heat coupling with the superconducting coil and a superconducting current limiter which is connected with the quenching heater group in series, the superconducting current limiter has a superconducting state with a resistance value being zero and an impedance state with a normal resistance value, and is used for limiting the current flowing through the quenching heater group.

Owner:GENERAL ELECTRIC CO

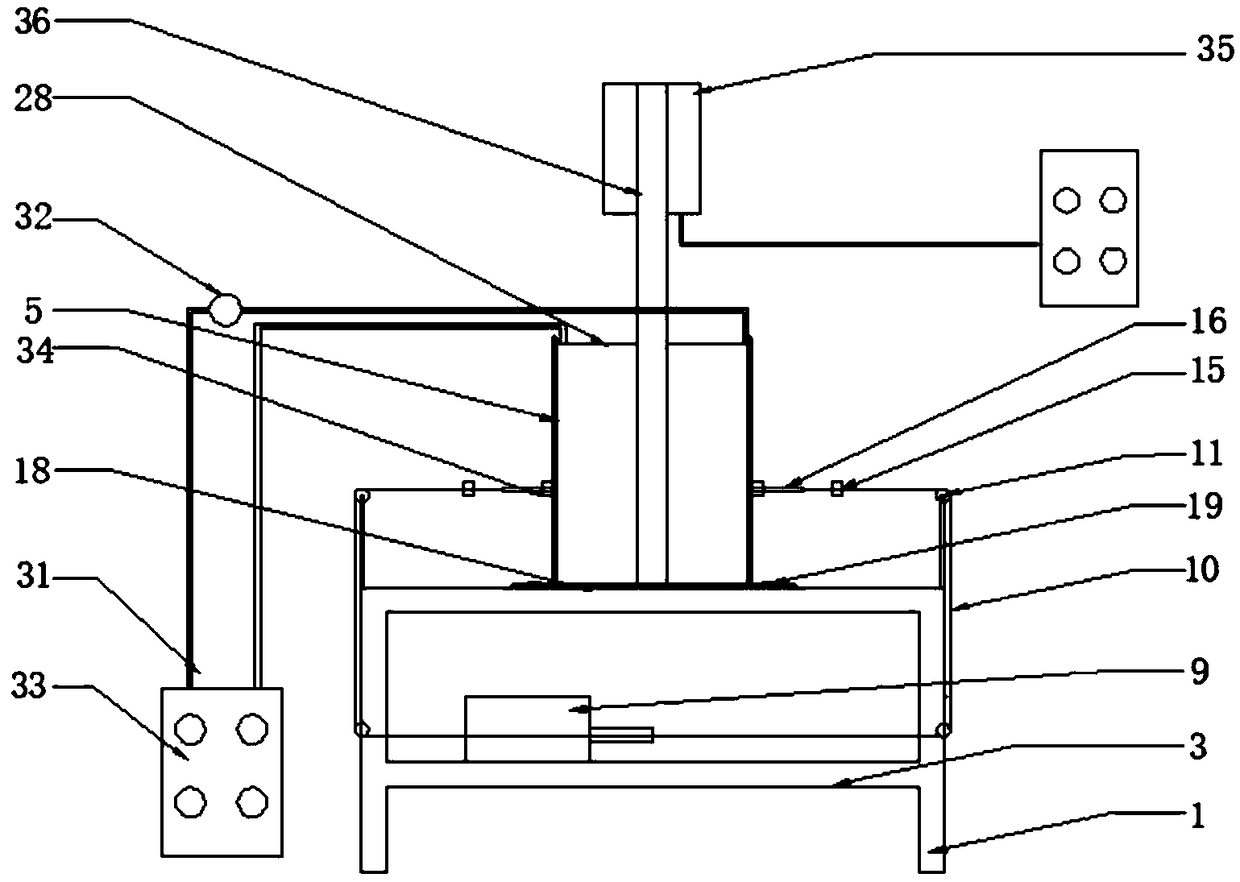

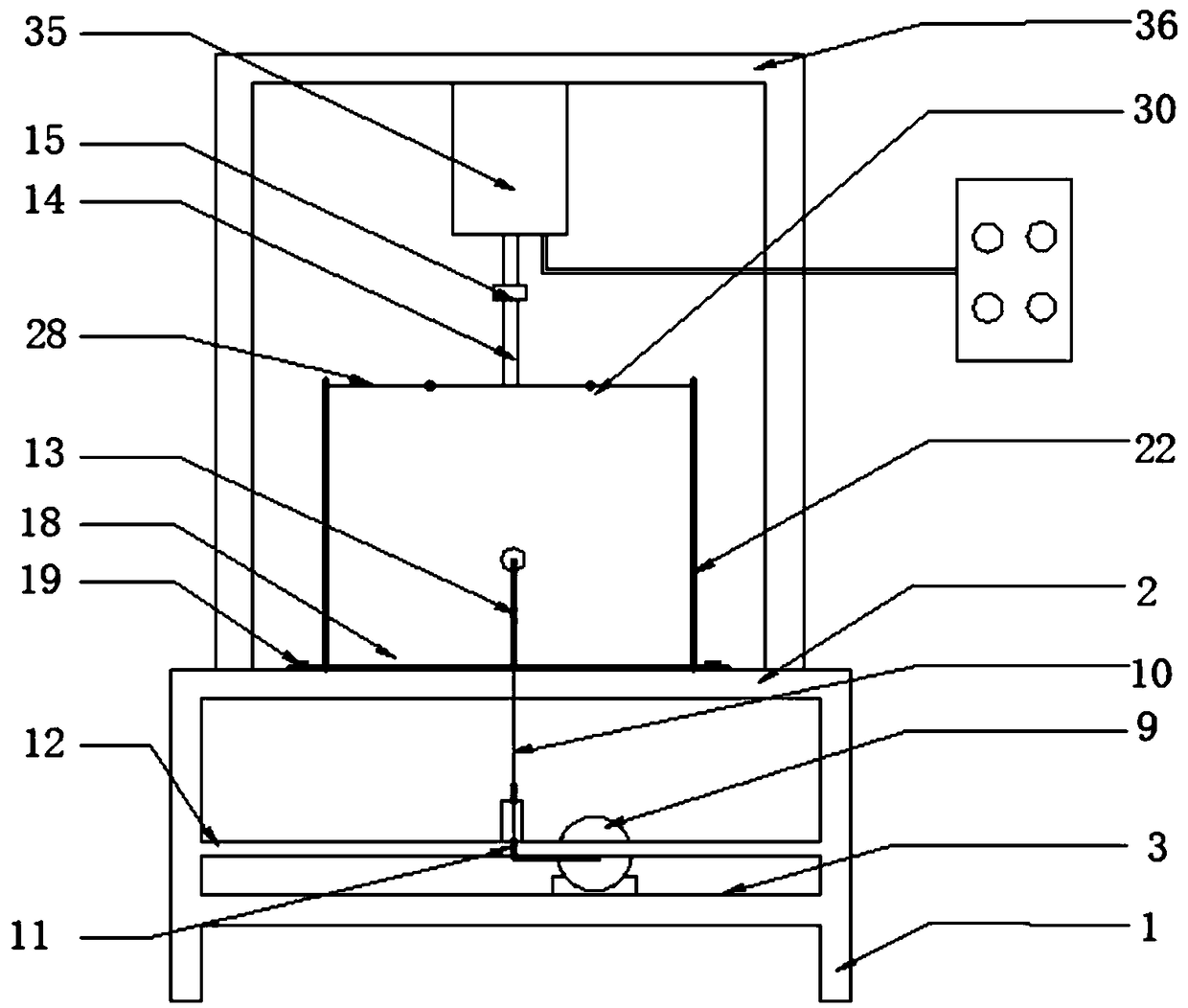

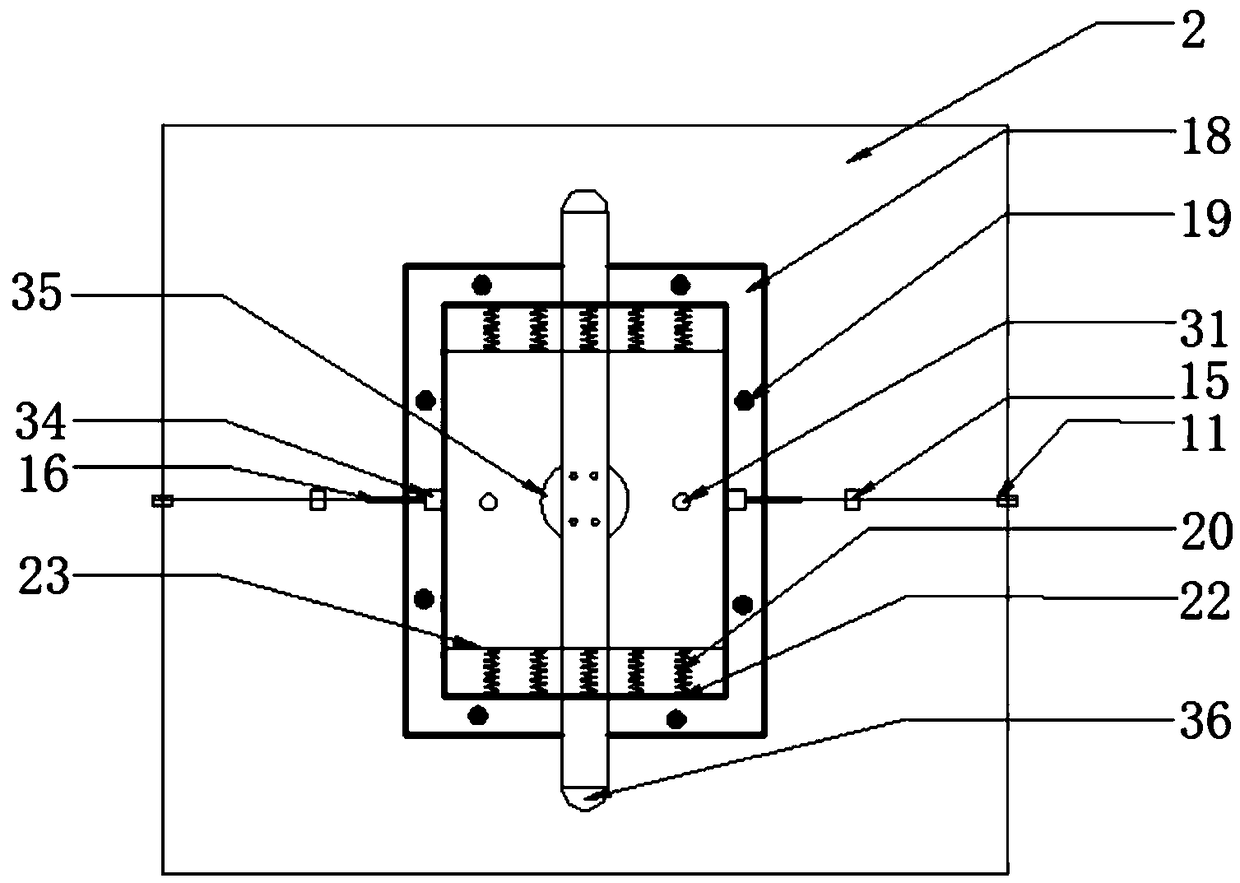

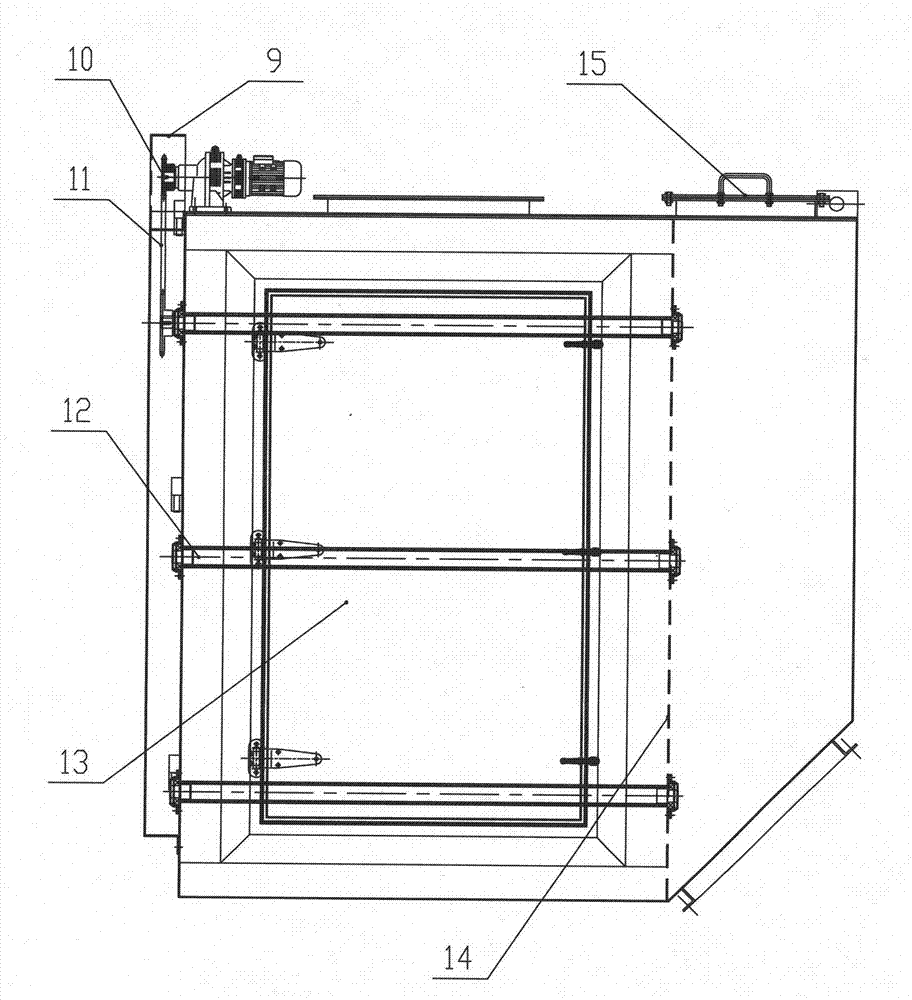

Tangential and normal resistance testing device for anchor chain and soil under equivalent elastic boundary

ActiveCN109374418ASmall sizeReduce the difficulty of experimental operationFoundation testingMaterial strength using tensile/compressive forcesNormal resistanceMooring system

The invention discloses a tangential and normal resistance testing device and method for anchor chain and soil under an equivalent elastic boundary. The device comprises a supporting rack, a transmission device, an air pressure loading system, a test box, a vertical displacement applying part, a tangential anchor chain unit, a normal anchor chain unit and the like. By employing an equal rigidity spring to simulate the elastic boundary, the size of the test box can be reduced greatly in the condition that the boundary condition is affected, so that the materials can be saved effectively and theexperimental operating difficulty can be reduced effectively. Meanwhile, the device can integrate tangential and normal resistance tests, can measure the tangential and normal interactions of the anchor chain and the soil, and can provide important design parameters for calculating a buried fragment of an engineering anchor chain. The device and method have important reference meaning in a mooring system of an anchor point below the sea bottom mud face.

Owner:ZHEJIANG UNIV

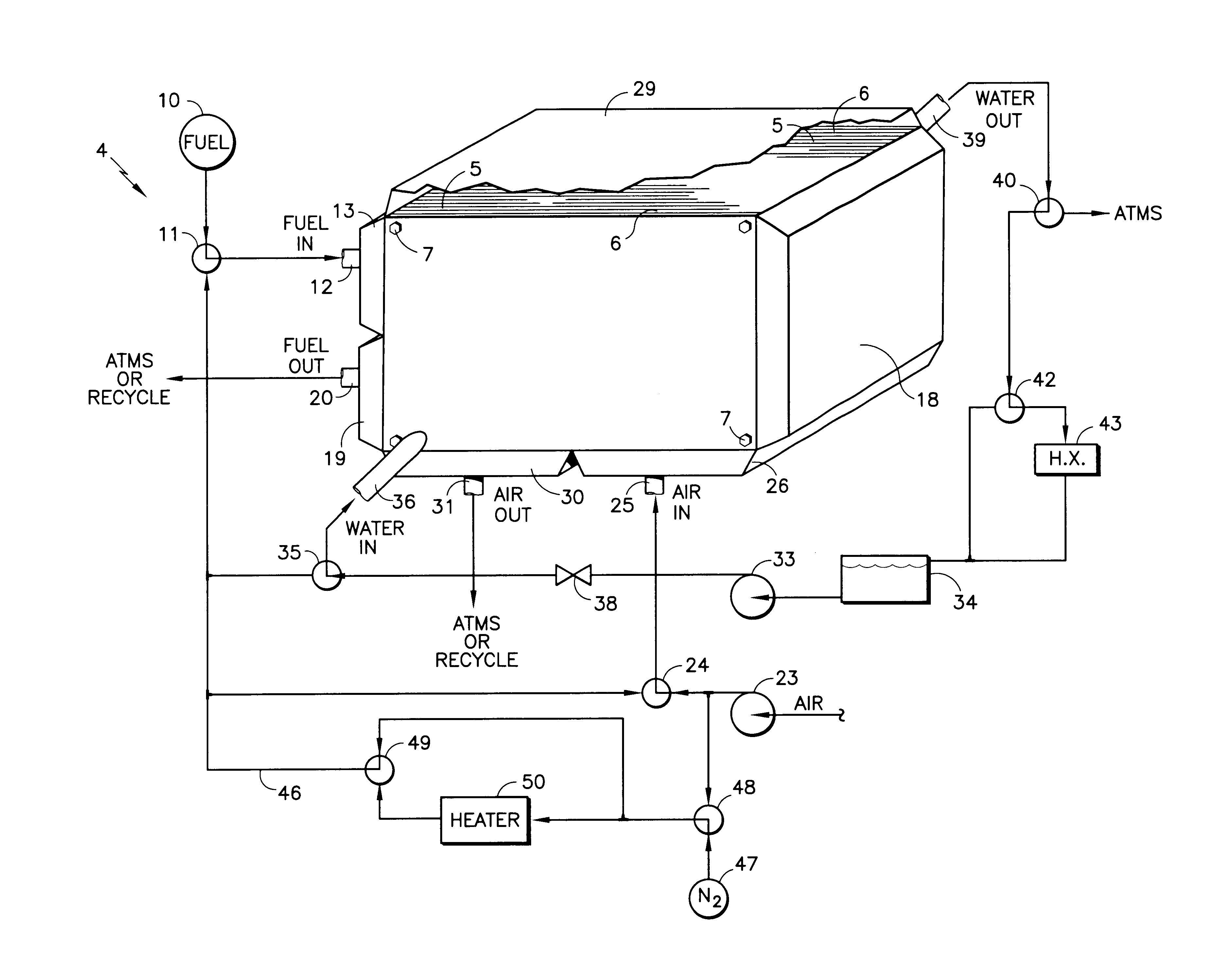

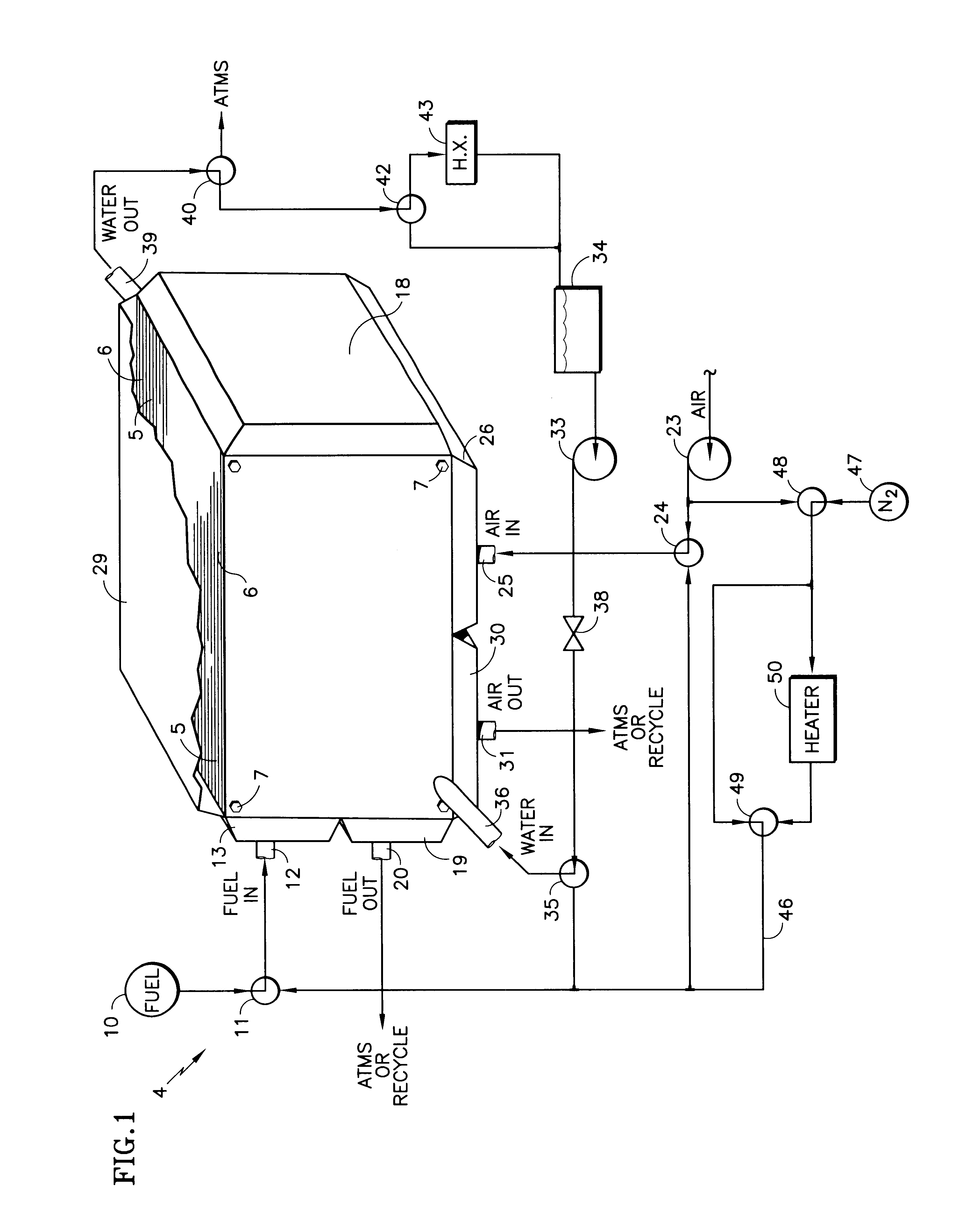

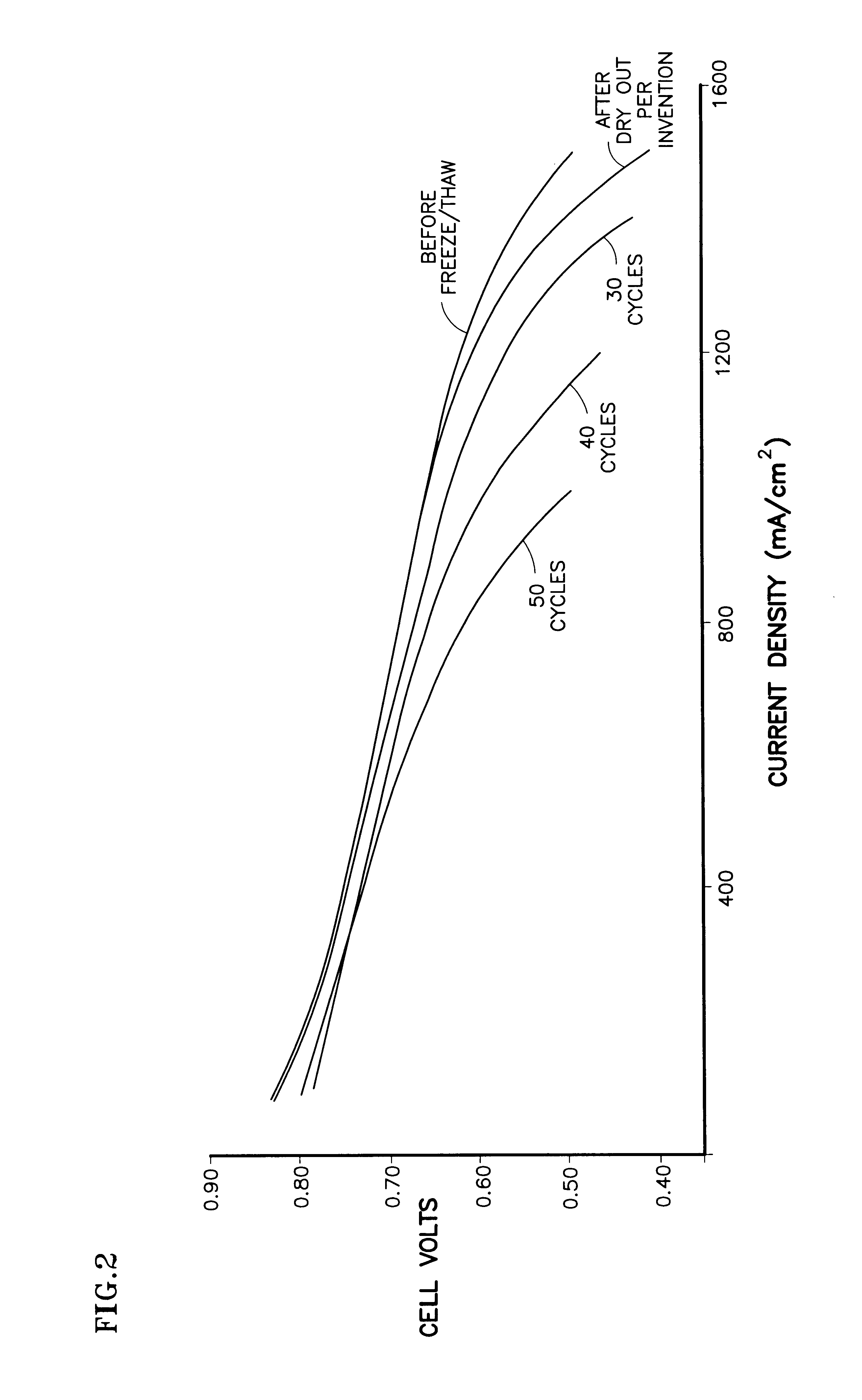

Performance recovery process for PEM fuel cells

InactiveUS6709777B2Restore performanceSpeed up the processFuel cell auxillariesSolid electrolyte fuel cellsElectrical resistance and conductanceFuel cells

Recovery of PEM fuel cell performance is achieved by evacuating (61, 62) or by flowing water absorbing gas (46) through, or both, the fuel flow field (12, 13, 19, 20), the air flow field (25, 26, 30, 31), and the water flow field (36, 39), while resistance of the individual cells, or of the fuel cell stack, is measured; the dry out process is continued until the resistance of the cells (or the resistance per cell, measured across the fuel cell stack as a whole), has increased by at least 5 to 1 (preferably 10 to 1) over the normal resistance of the cells. The water absorbing gas may be air (23) or nitrogen (47); it may be at ambient temperature or heated (50).

Owner:AUDI AG

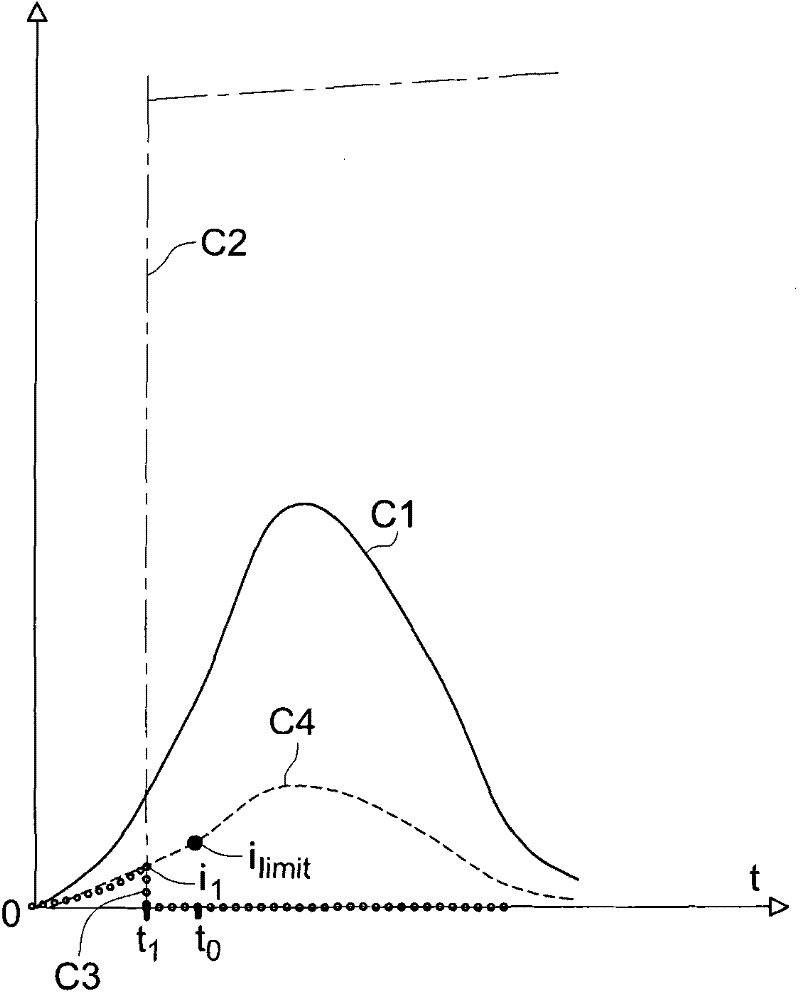

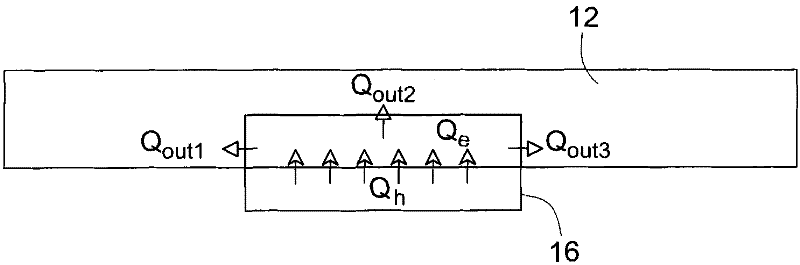

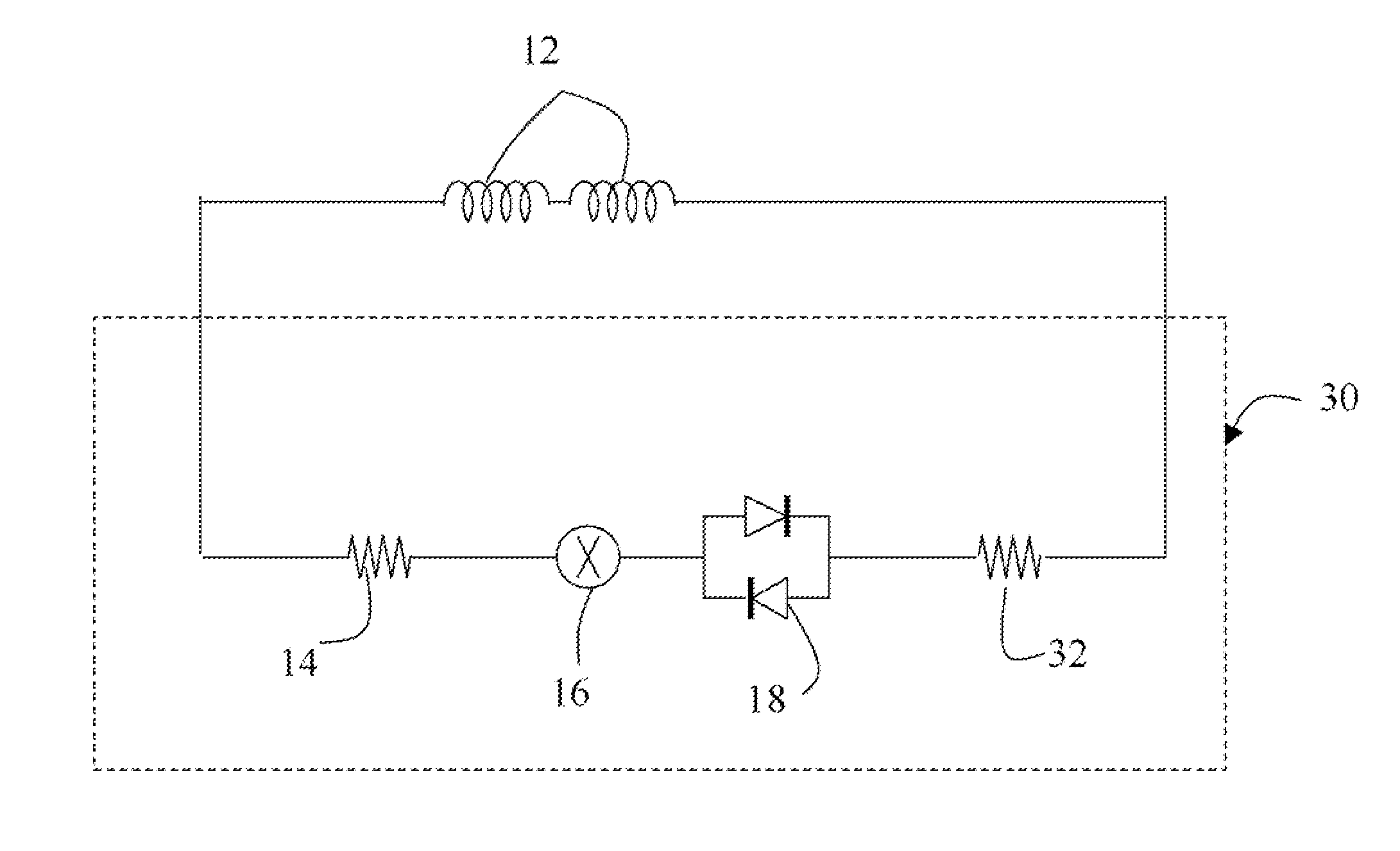

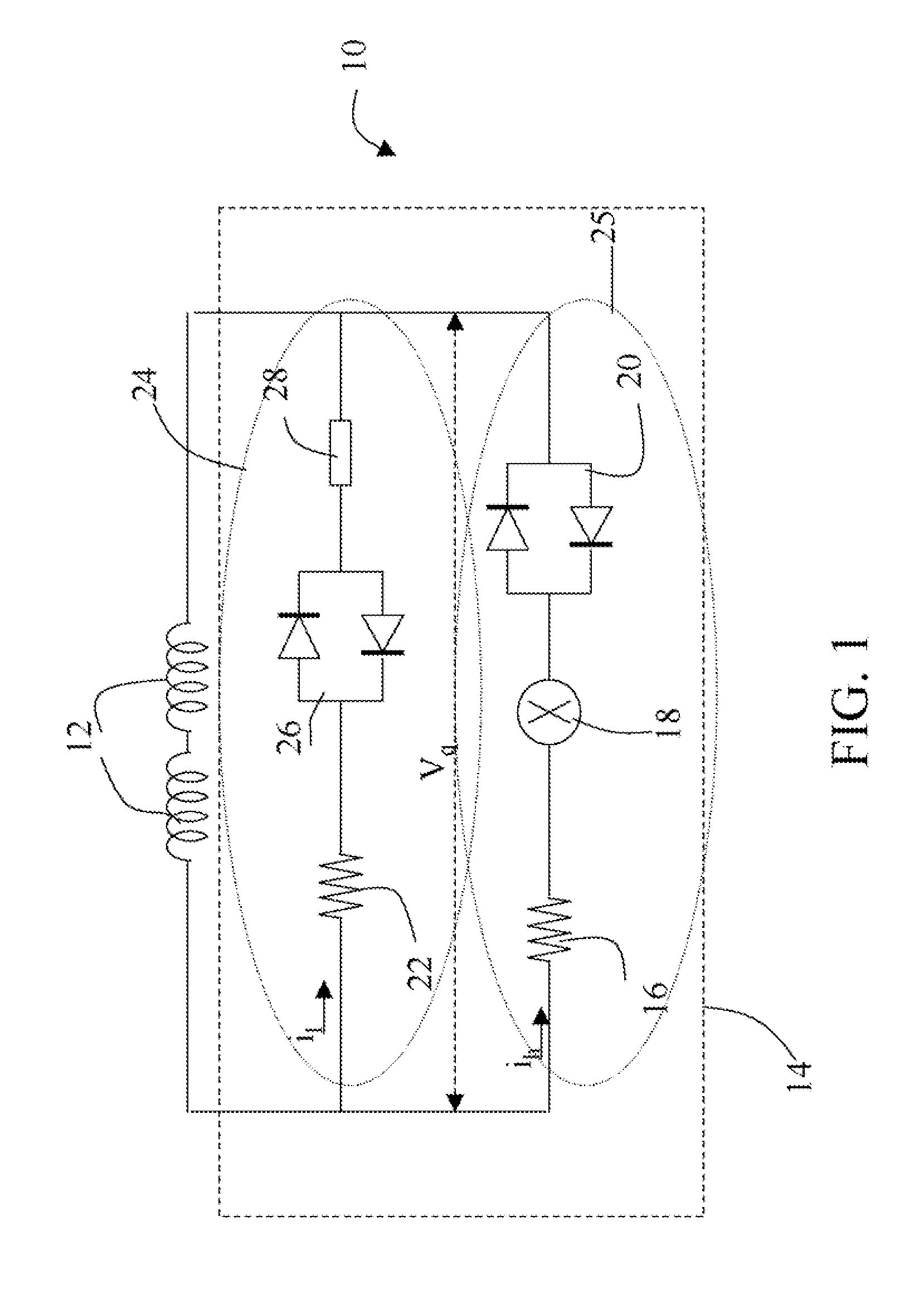

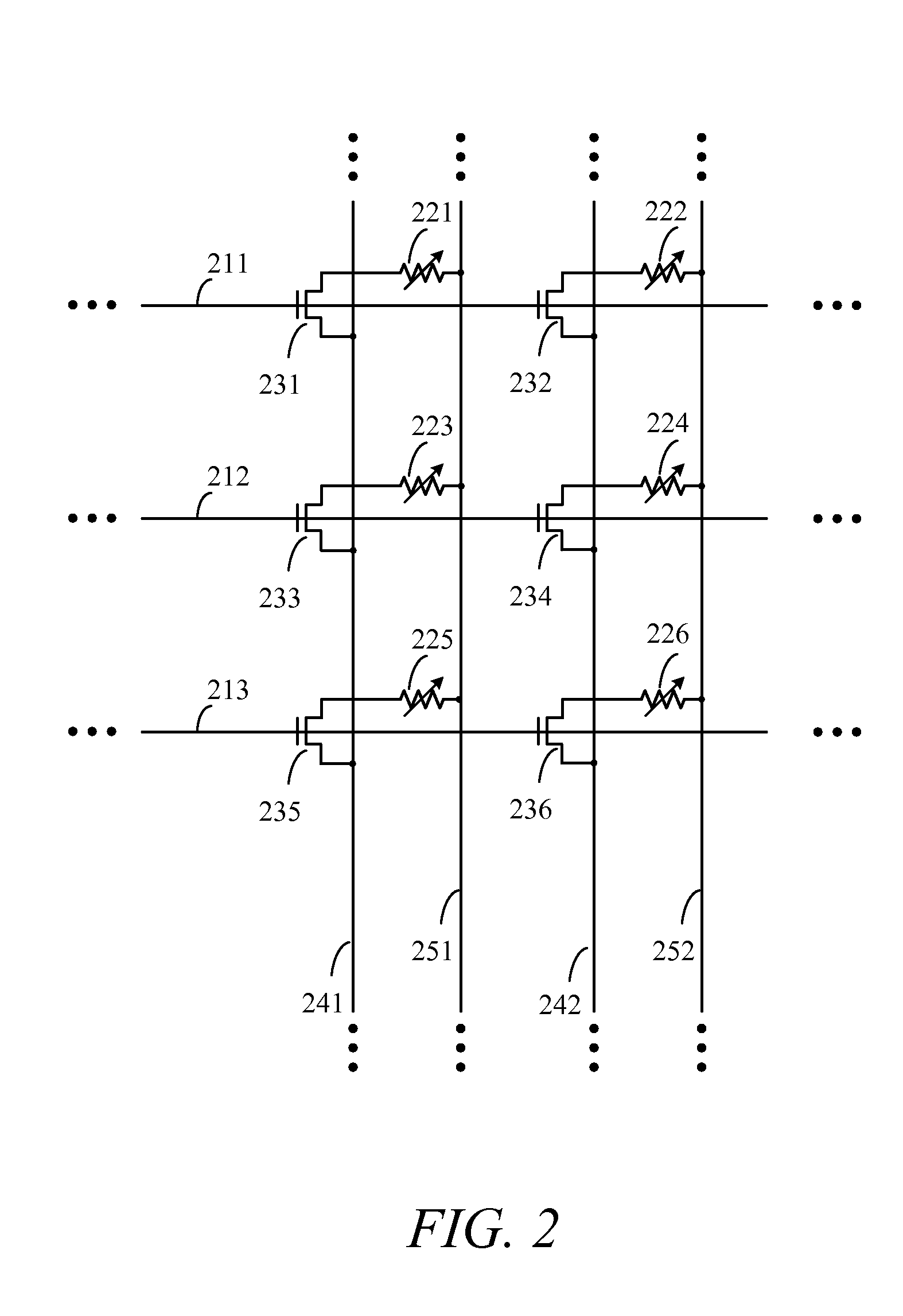

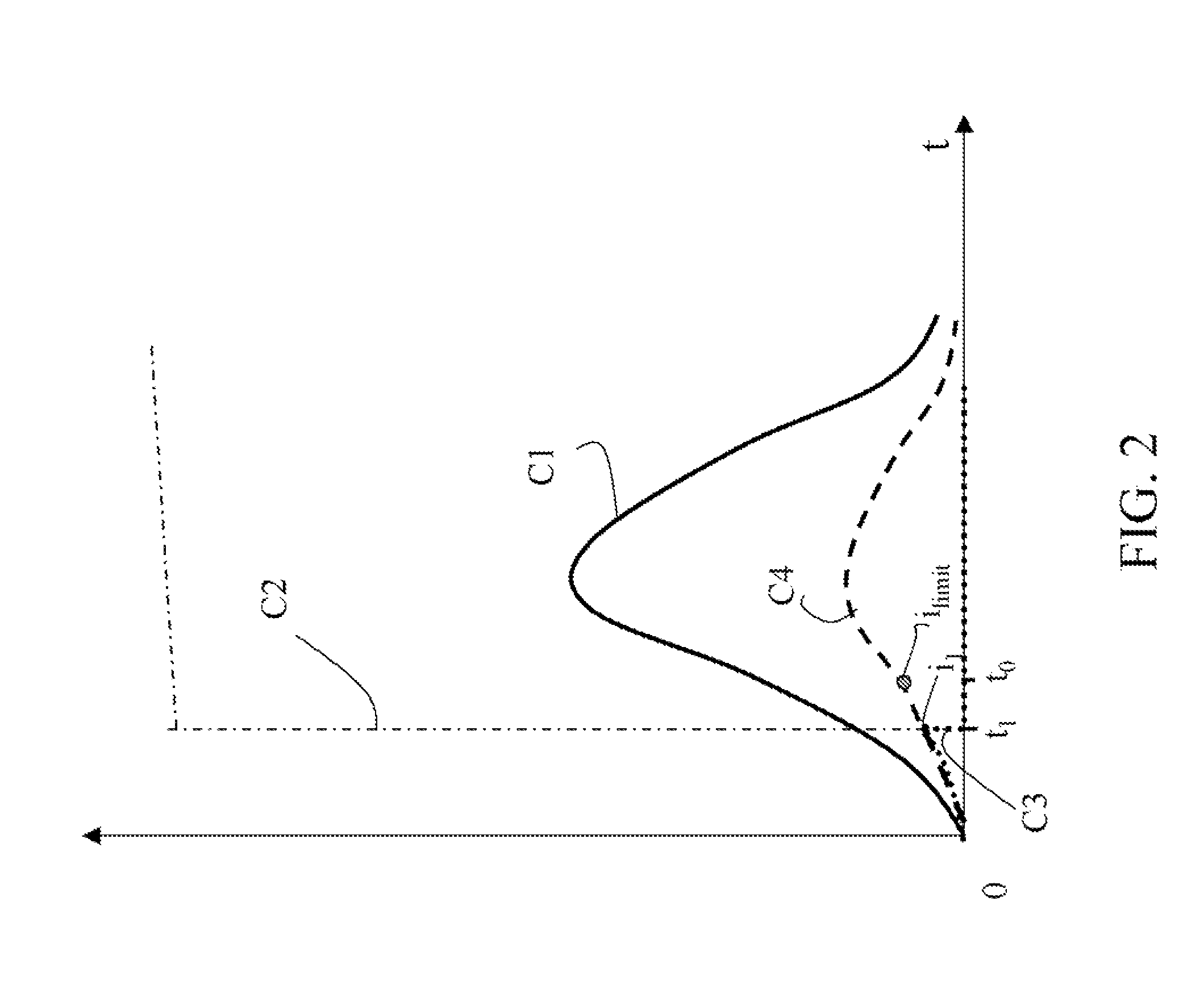

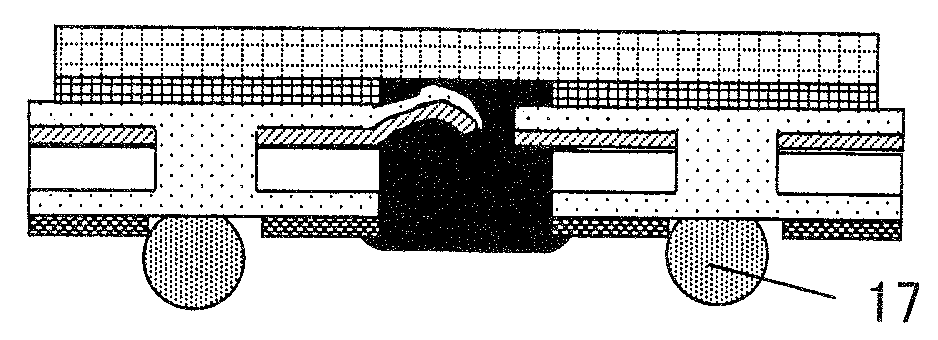

Quench protection circuit for superconducting magnet coils

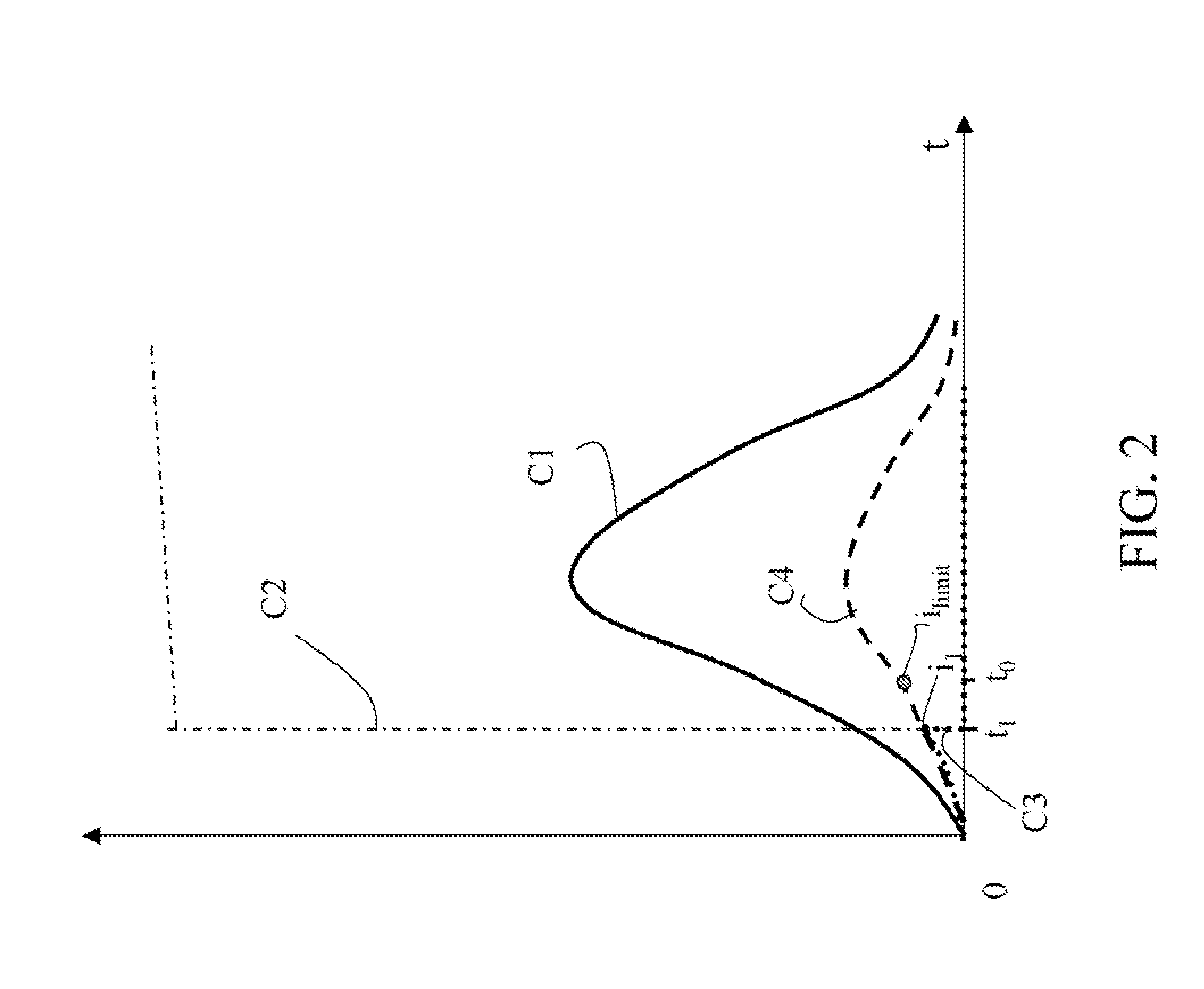

ActiveUS20120071326A1Reduce trafficImprove the immunitySuperconductors/hyperconductorsMagnetic field measurement using superconductive devicesNormal resistanceSuperconducting Coils

A superconducting magnet includes at least one superconducting coil and a quench protection circuit electrically coupled to said at least one coil in parallel. The circuit includes at least one quench heater assembly thermally coupled to the at least one coil, and at least one superconducting current limiter electrically connected in series with the at least one quench heater assembly. The superconducting current limiter has a superconducting state with zero resistance, and a normal state with a normal resistance to decrease an electric current flowing through the quench heater assembly.

Owner:GENERAL ELECTRIC CO

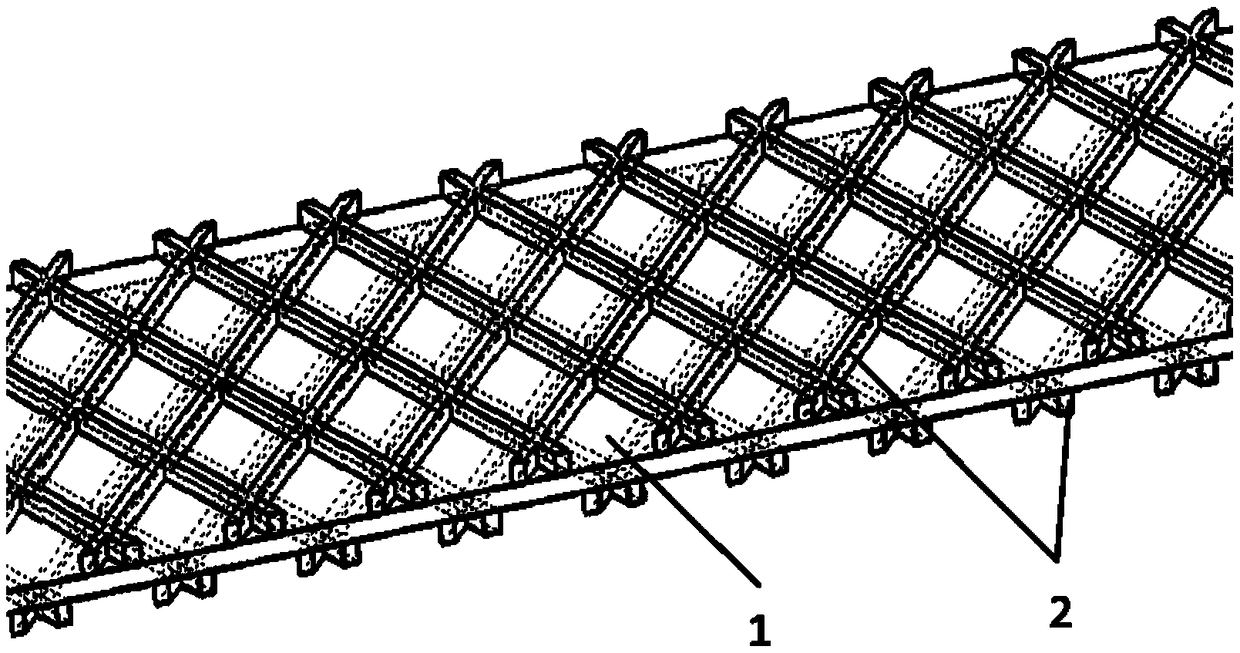

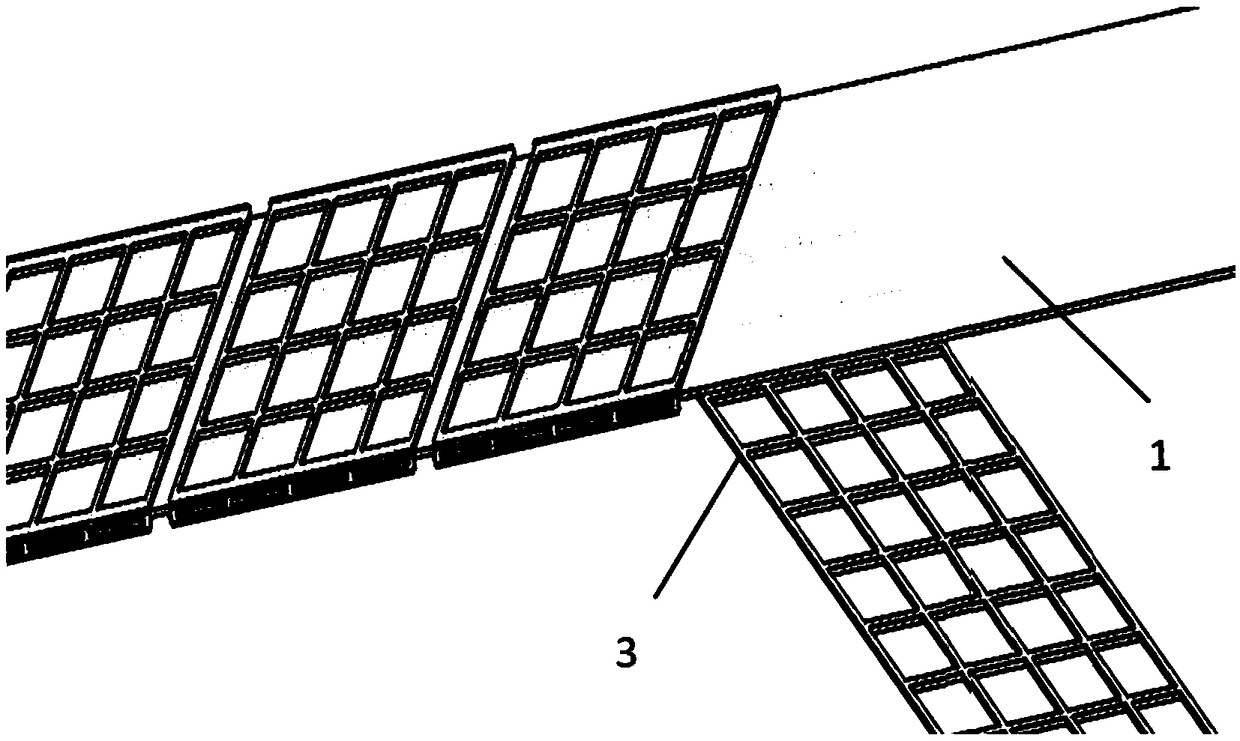

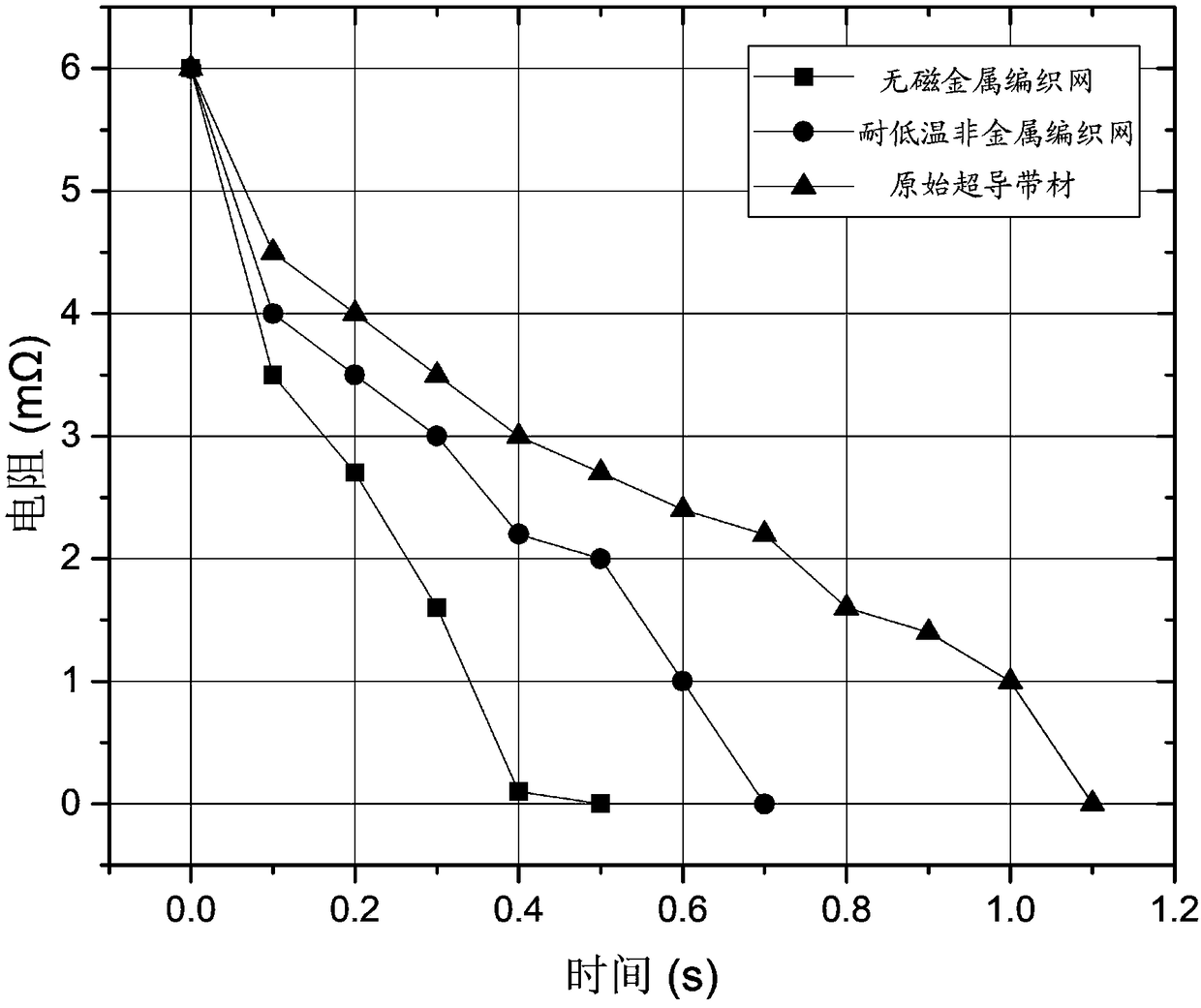

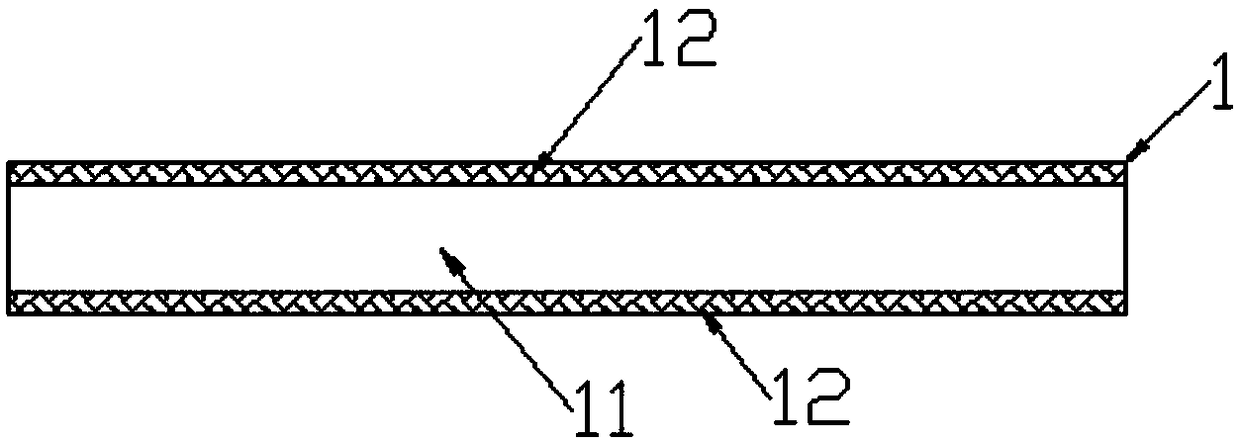

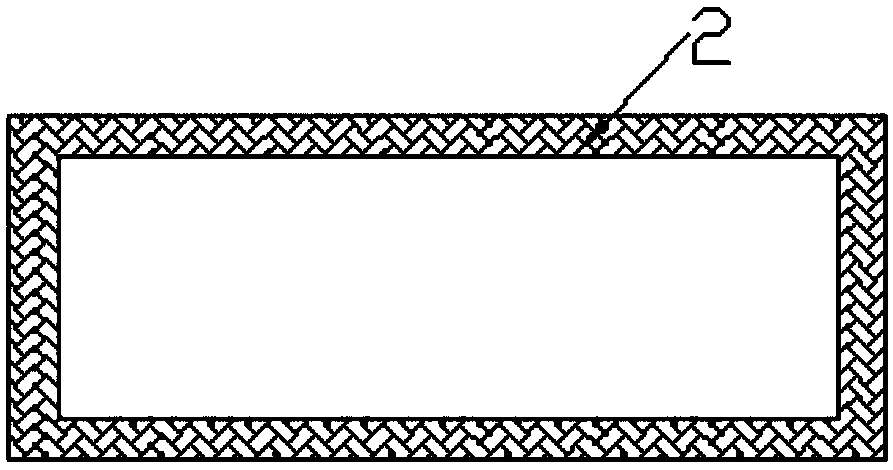

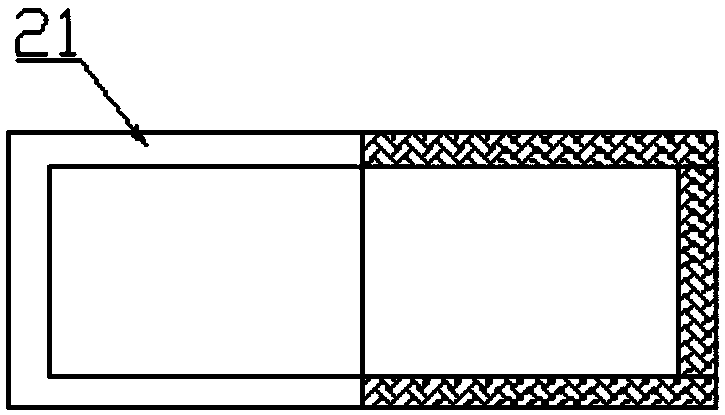

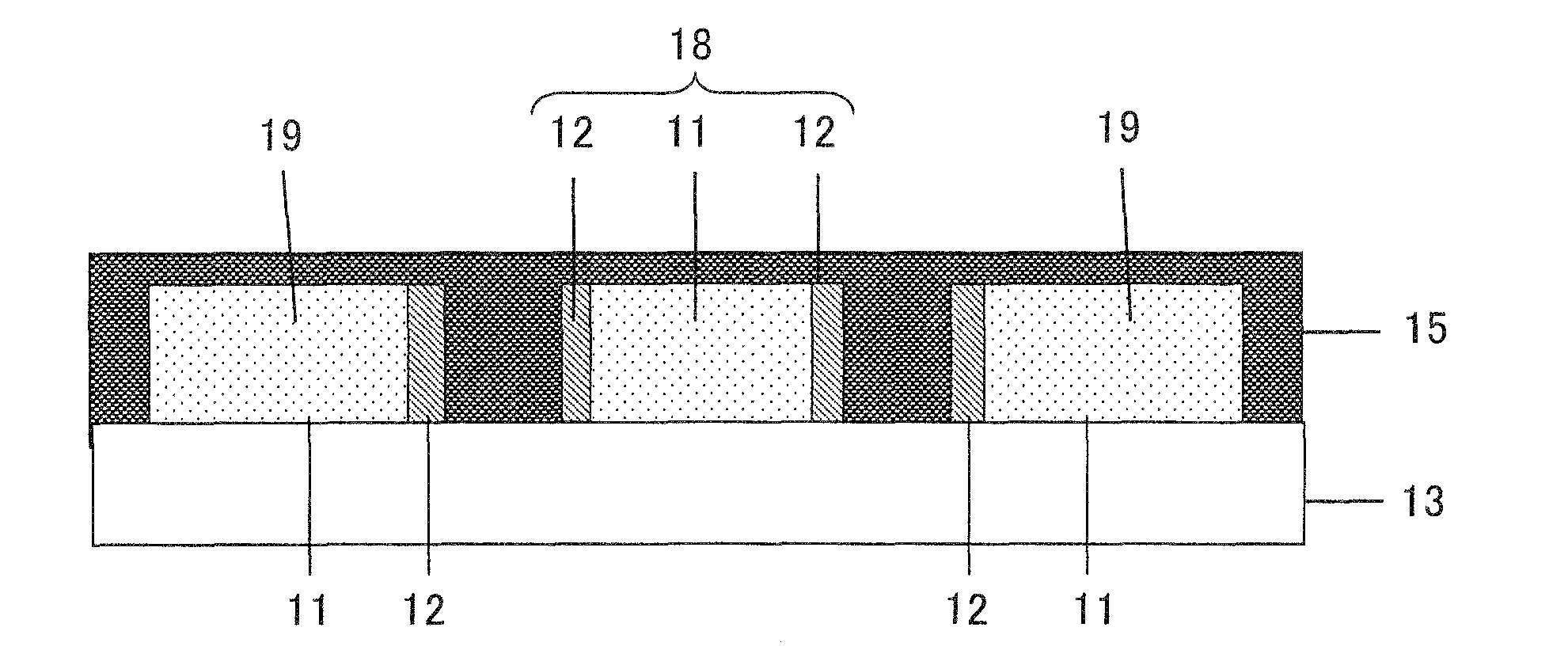

Superconductive strip material surface layer, superconductive strip material, and superconductive coil

PendingCN109300610ADiffusion fastImprove heat exchange efficiencySuperconductors/hyperconductorsSuperconductor devicesSurface layerNormal resistance

The embodiment of the invention discloses a superconductive strip material surface layer, and the surface layer is provided with a mesh grid structure which is disposed on the surface of a superconductive strip material. The surface layer provided by the invention solves a technical problem that the steam layer generated by the surface when a superconductor is in a normal resistance state greatlyreduces the heat exchange efficiency between the superconductor and liquid nitrogen. In addition, the embodiment of the invention also discloses a superconductive strip material and a superconductivecoil.

Owner:GUANGDONG POWER GRID CO LTD +1

Oxide high-temperature superconducting wire and method of producing the same

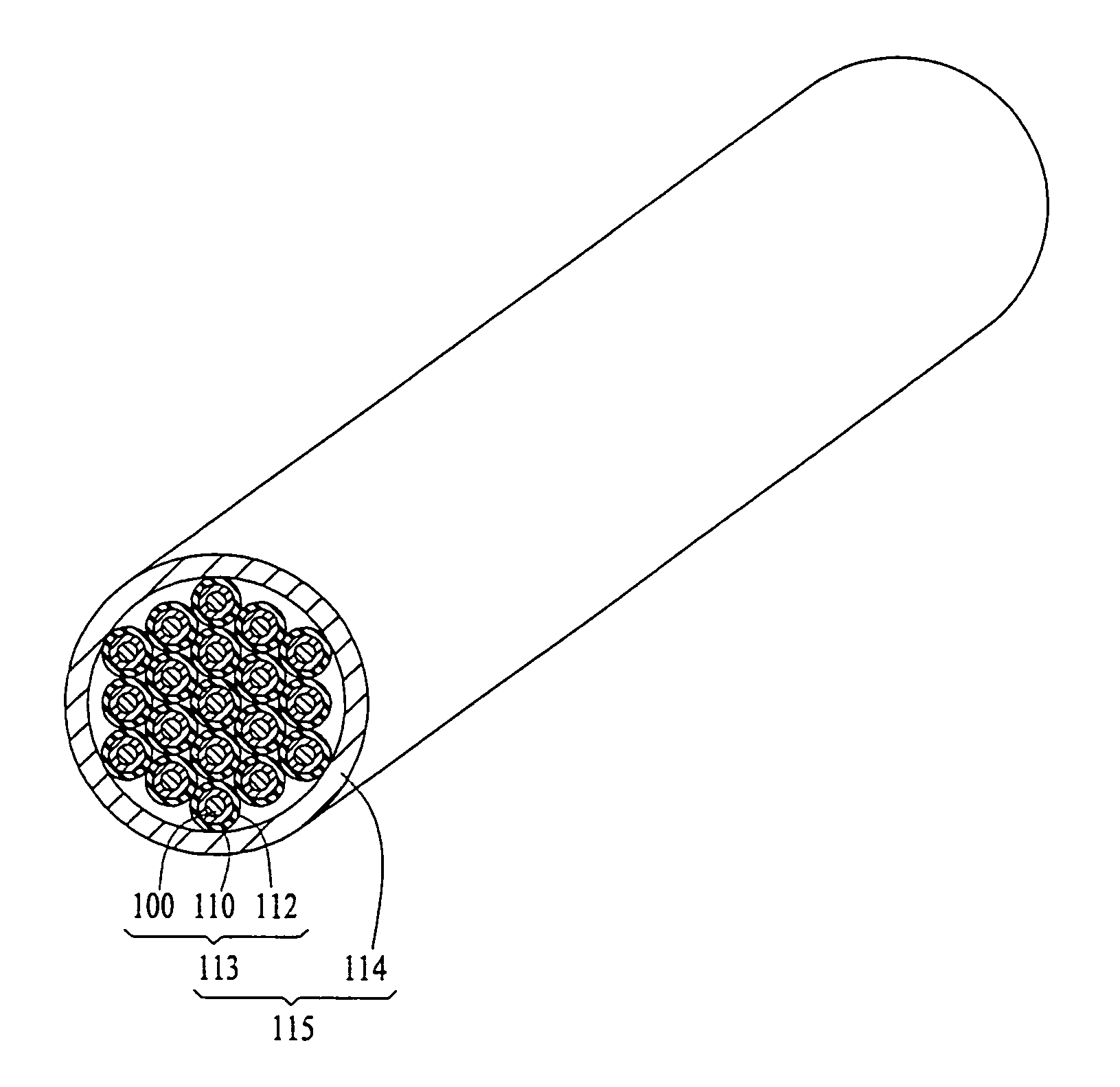

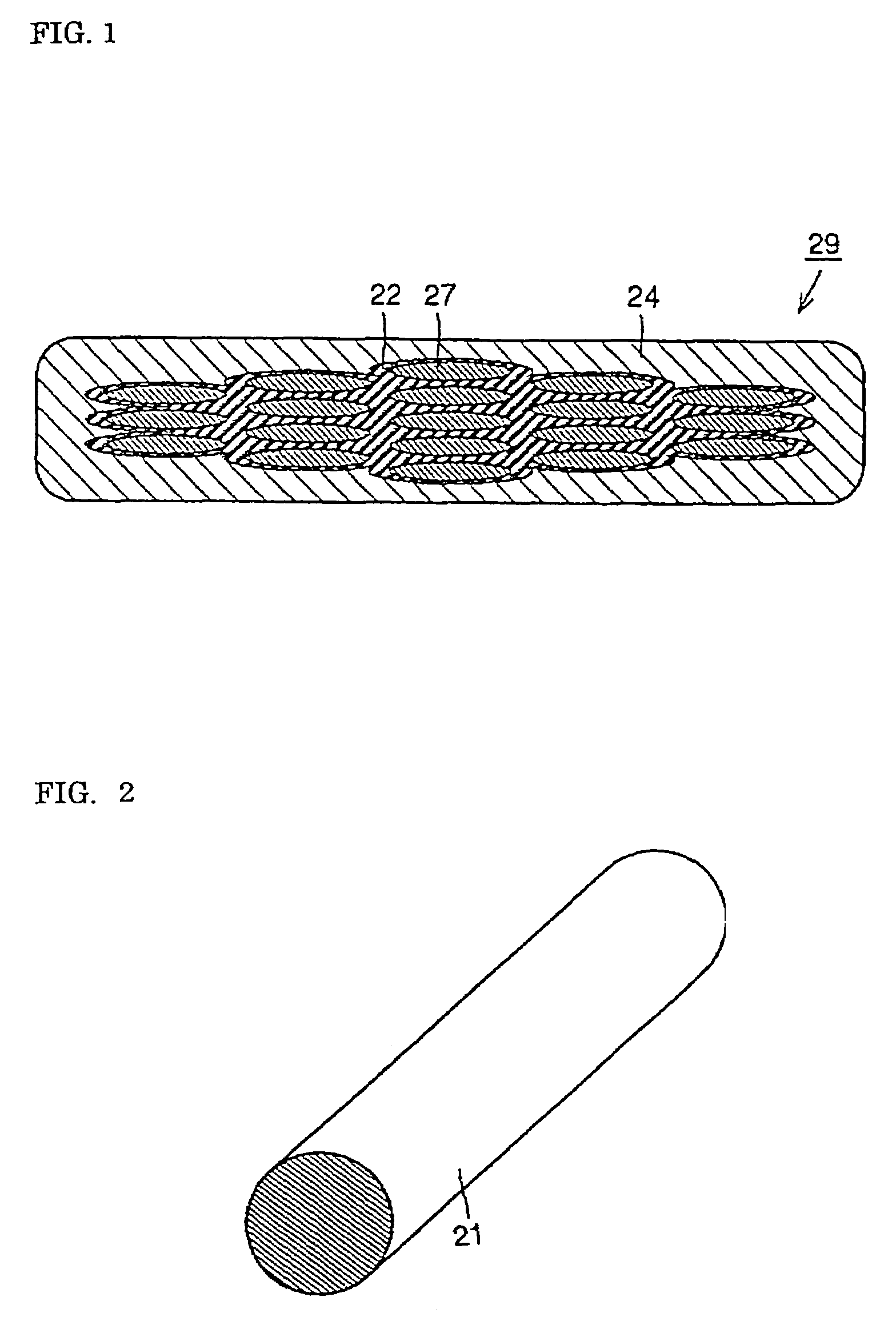

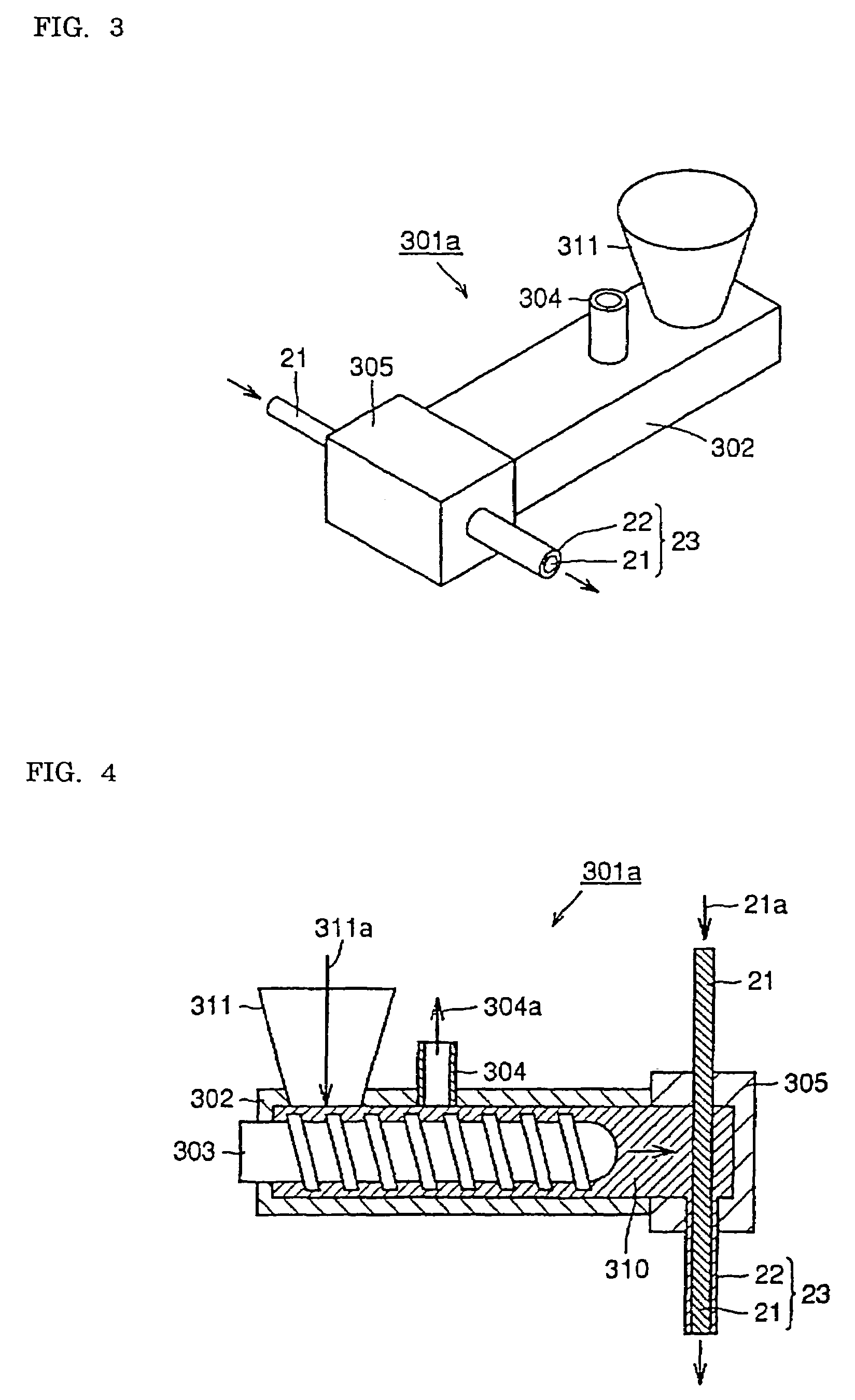

InactiveUS7162287B2Reducing AC lossSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentHigh densityNormal resistance

This invention relates to an oxide superconducting wire comprising oxide superconducting filaments, a high-density ceramic layer uniformly surrounding each of the filaments, and a silver sheath that directly covers the ceramic layer. The ceramic layer becomes non-superconducting when the filaments are cooled to an operating temperature of oxide superconductors. The oxide superconductors can be isolated by the ceramic that acts as a highly resistive material or an insulator. A high normal resistance is achieved, and thereby AC loss is reduced remarkably.

Owner:SUMITOMO ELECTRIC IND LTD

Manganese doped negative temperature coefficient singlecrystalline silicon heat sensitive resistance

InactiveCN1619717ASimple processLower resistanceNegative temperature coefficient thermistorsSemiconductor materialsHeat sensitive

This invention refers to manganese doped negative temperature coefficient monocrystalline silicon thermistor, wherein the manganese is doped into monocrystalline silicon by vacuum high temperature diffusion of metal manganese and manganese nitrate coating, the manganese atom forms deep donor level, monocrystalline silicon forms highly compensated semiconductor material, as temperature raising the deep donor level trapped carrier transits to conduction band resulting in material resistivity change and present heat sensitive property, the change of material constant B and normal resistance at 25 degree centigrade can be obtained by changing diffusion temperature and time.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Thermal treatment method for railway wagon sliding chute wearing plate and side frame column wearing plate

ActiveCN102676753AImprove heat treatment effectUniform heat treatment hardnessFurnace typesDraw-gearPotassium nitrateNormal resistance

The invention discloses a thermal treatment method for a railway wagon sliding chute wearing plate and a side frame column wearing plate. The thermal treatment method is characterized by comprising at least the following steps of: (1) heating: tidily placing the wearing plates in a loading frame, and heating in a normal resistance furnace, wherein the heating temperature is 20-30 DEG C higher than that of the normal process, full fusion of total elements in a workpiece into a matrix structure is facilitated, and uniform and consistent hardness after quenching is guaranteed; (2) quenching in a nitrate bath tank of 260-300 DEG C other than in conventional water or oil, wherein the formula of a nitrate bath comprises 50 percent of potassium nitrate and 50 percent of sodium nitrate respectively; and adding 1-5 percent of water before quenching according to different materials and sizes of the wearing plates, wherein the isothermal cooling time in the nitrate bath tank is 45-90 minutes according to different sizes of the wearing plates; (3) taking the workpiece out of the nitrate bath tank, draining the residual nitrate bath and cleaning residual salt in hot water; and (4) checking hardness and deformation of the workpiece and performing tempering treatment if the hardness is high.

Owner:株洲春华实业有限责任公司

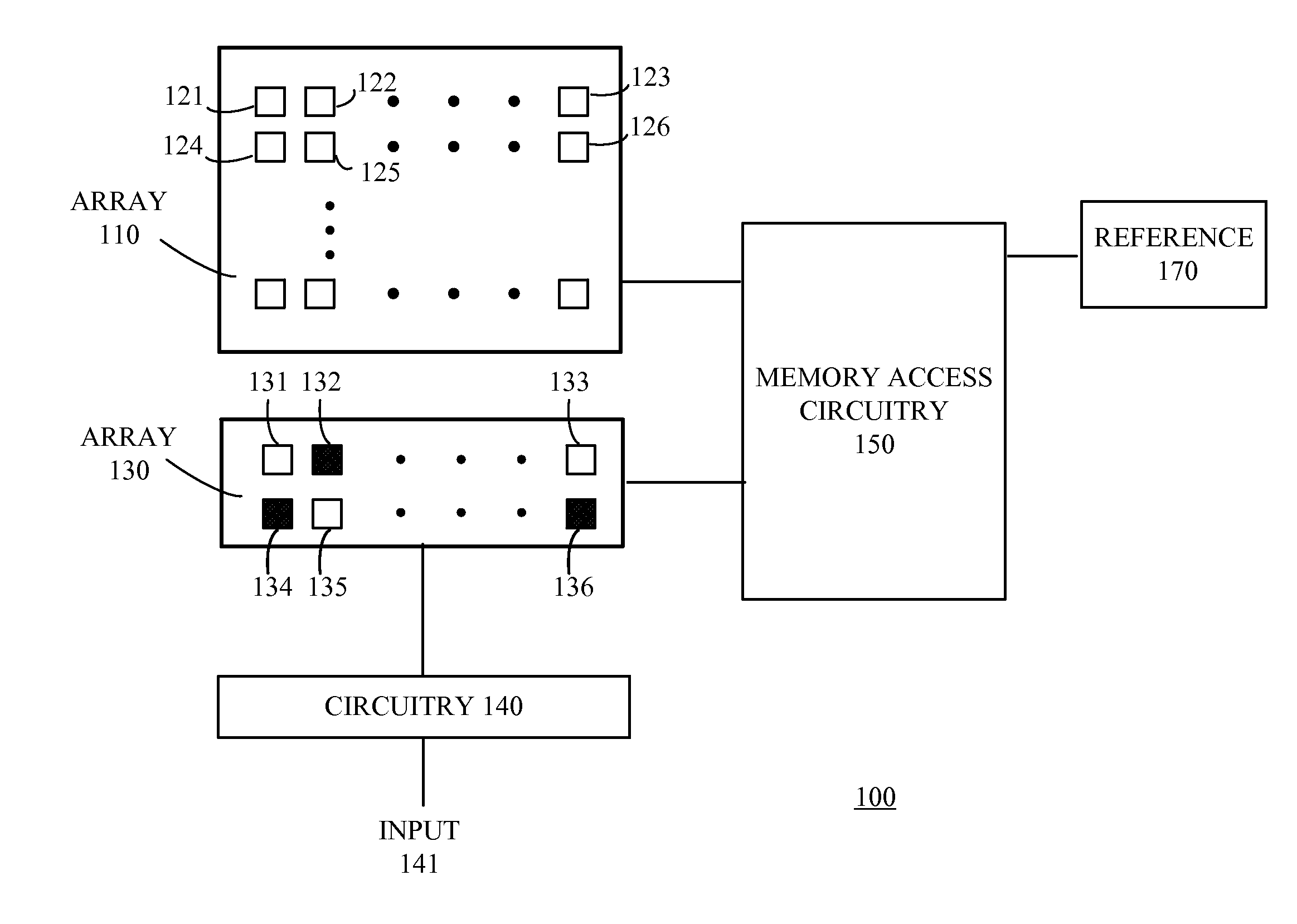

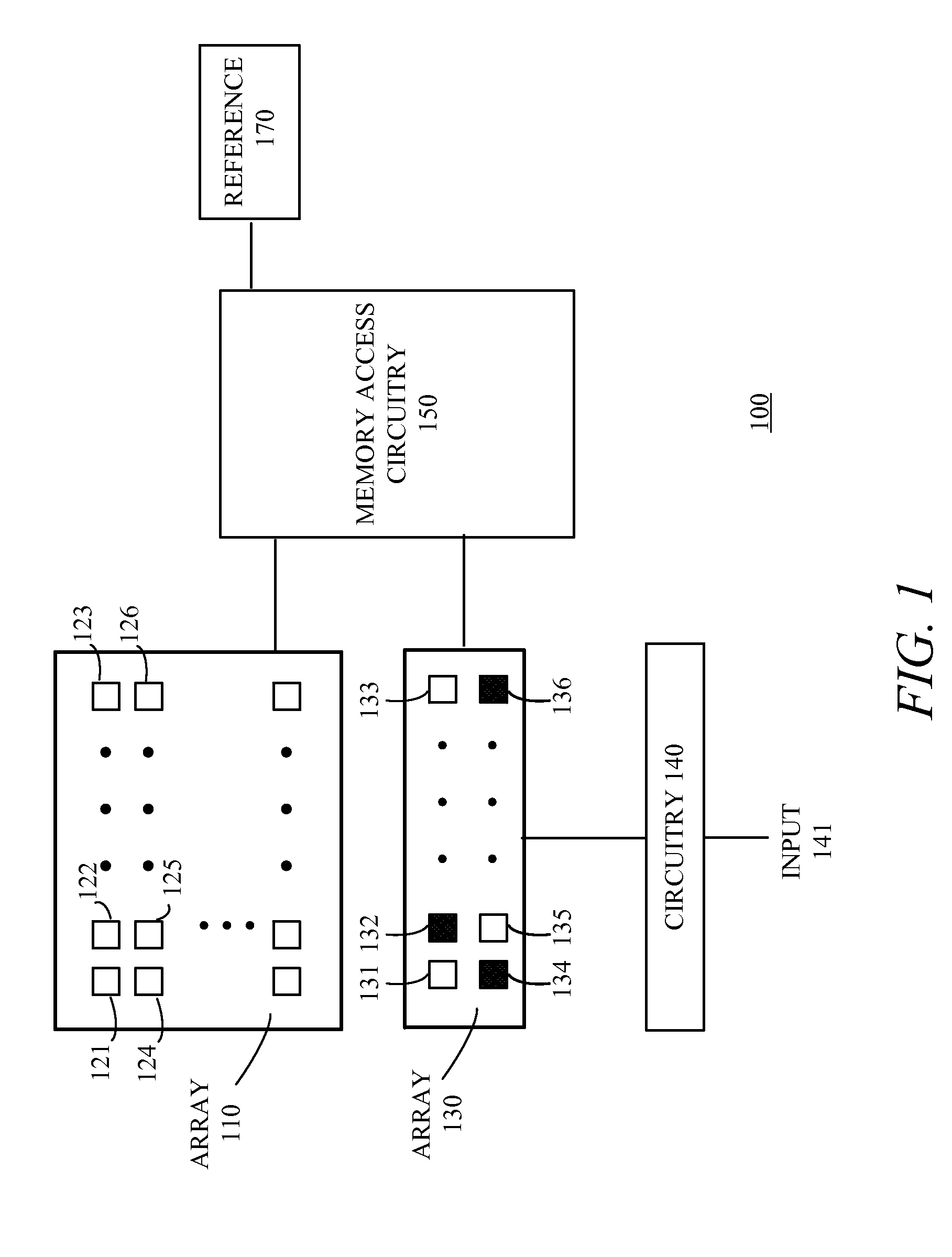

High temperature data retention in magnetoresistive random access memory

Techniques and circuits for storing and retrieving data using spin-torque magnetic memory cells as anti-fuses are presented. Circuits are included to allow higher-magnitude voltages and currents to be applied to magnetic memory cells to intentionally break down the dielectric layer included the magnetic tunnel junction. Magnetic memory cells having a normal-resistance magnetic tunnel junction with an intact dielectric layer are used to store a first data state, and magnetic memory cells having a magnetic tunnel junction with a broken-down dielectric layer are used to store a second data state. Data can be stored in such a manner during wafer probe and then later read out directly or copied into other magnetic or non-magnetic memory on the device for use in operations after the device is included in a system.

Owner:EVERSPIN TECHNOLOGIES

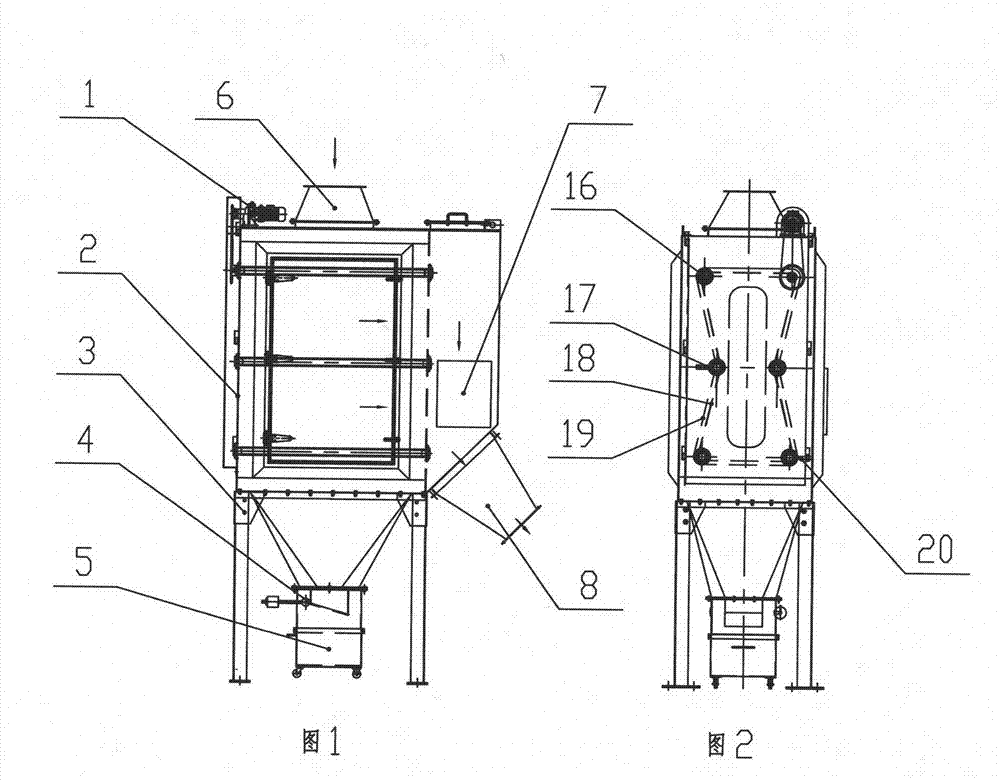

Automatic cleaning deduster with butterfly-shaped crawler belt

InactiveCN103239954AHandling large air volumeImprove dust removal efficiencyDispersed particle filtrationAir volumeNormal resistance

The invention provides an automatic cleaning deduster with a butterfly-shaped crawler belt, comprising a decelerator 1, a cabinet 2, a base 3, a cindervalve 4, a dust barrel 5, an air-supply pipe 6, an electric cabinet 7 and an air discharging pipe 8. As shown in views, the upper part is the cabinet, and the lower is the base. The decelerator is arranged on the top of the cabinet for driving transmission shafts in the cabinet, filtration cloth is sleeved on a plurality of transmission shafts to form the butterfly-shaped crawler belt; a separator plate with an opening in the medium is arranged in the cabinet, and divides the cabinet into an air inlet chamber and an outlet chamber; a fixed row brush is installed at a proper position in the lower of the cabinet; and the electric cabinet is installed out of the cabinet. The base is used for supporting the cabinet, and also for fixing a dust bucket under the cabinet, and the lower of the dust bucket is connected with the cindervalve and the dust barrel. The deduster is a novel duster used in an industrial dedusting flow, and has advantages of large treatment wind amount, high dedusting efficiency, small resistance, long using period (one to more years), and maintenance-free, and can continuously and stably run in a normal resistance range.

Owner:李路

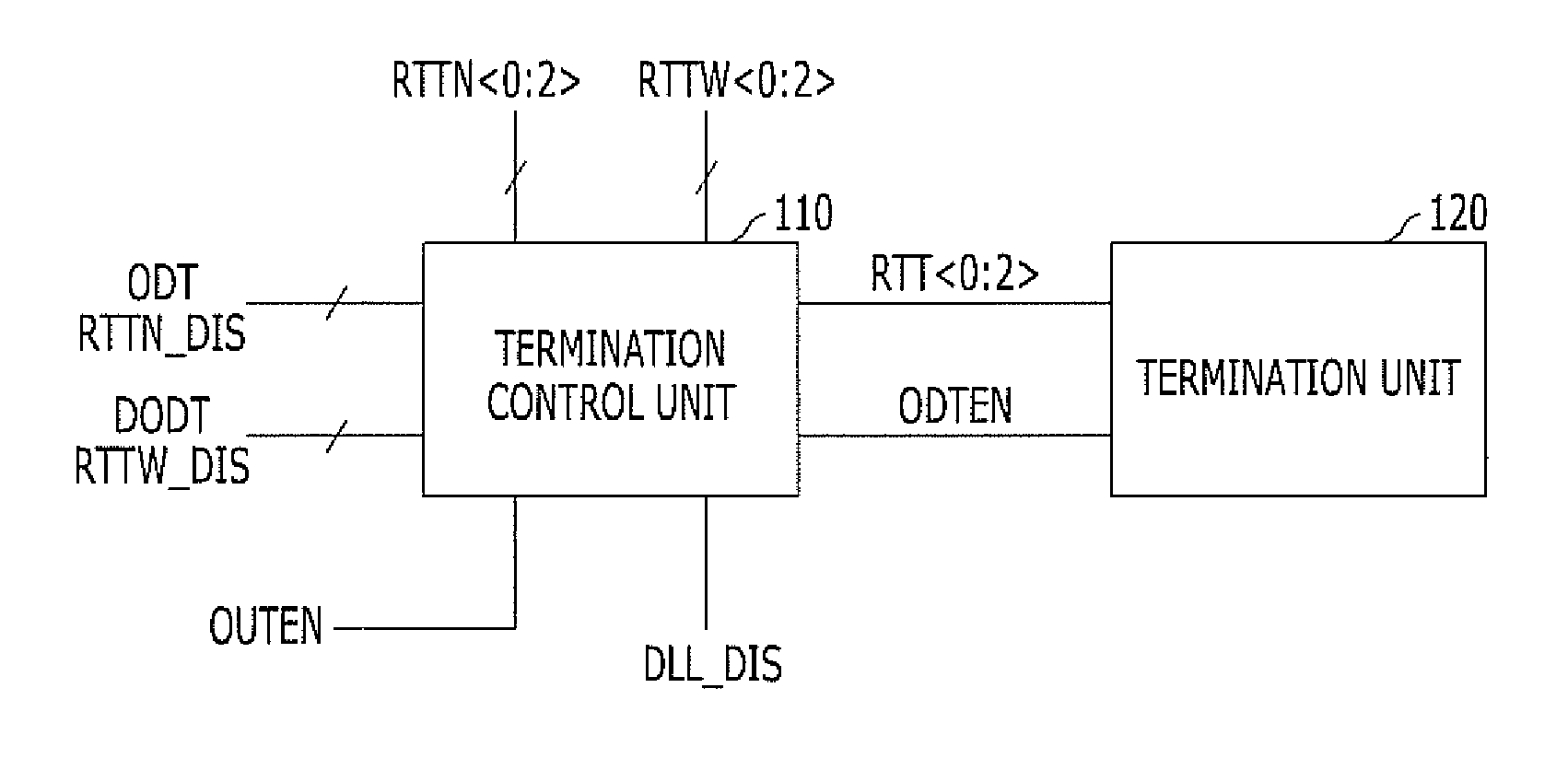

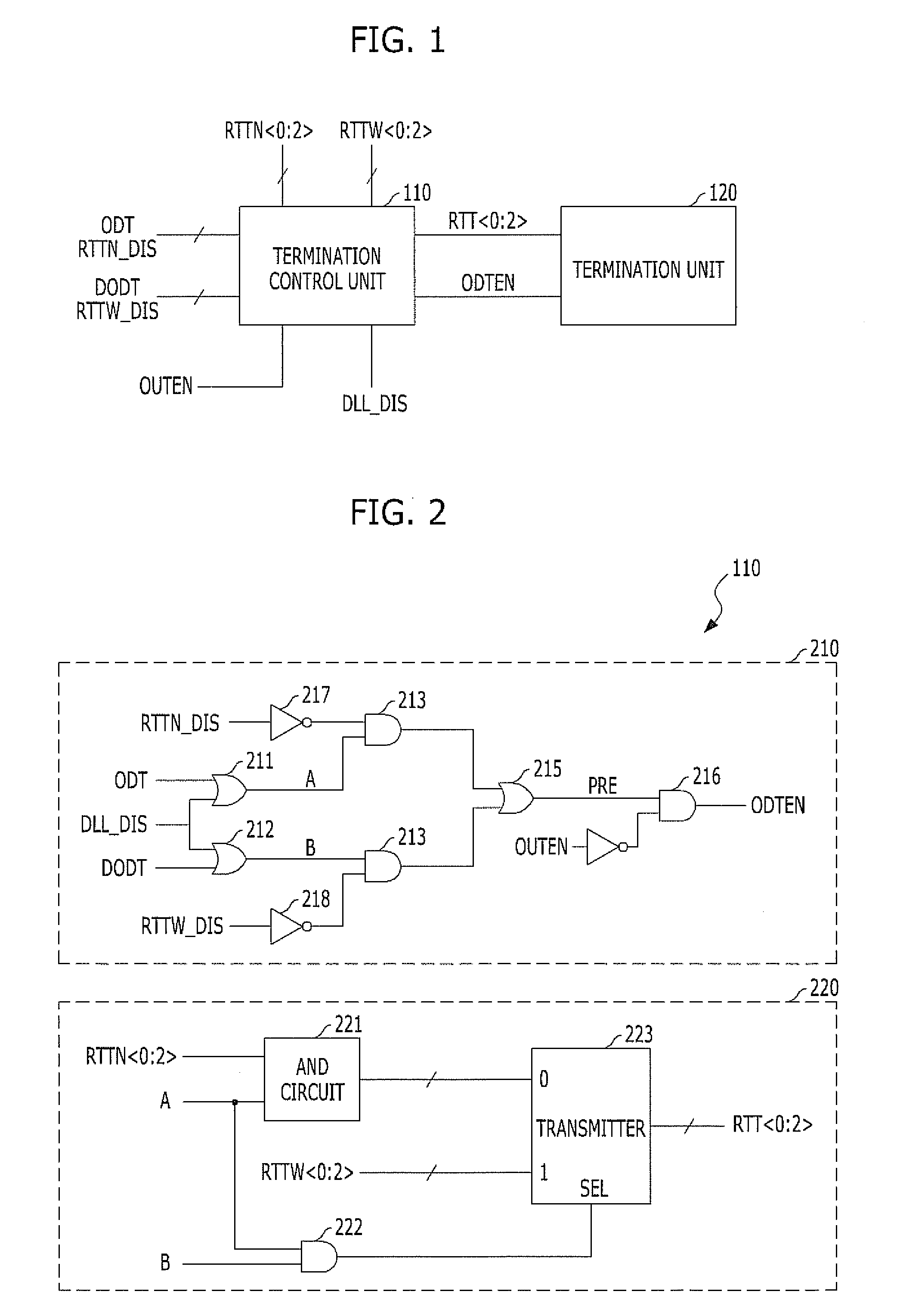

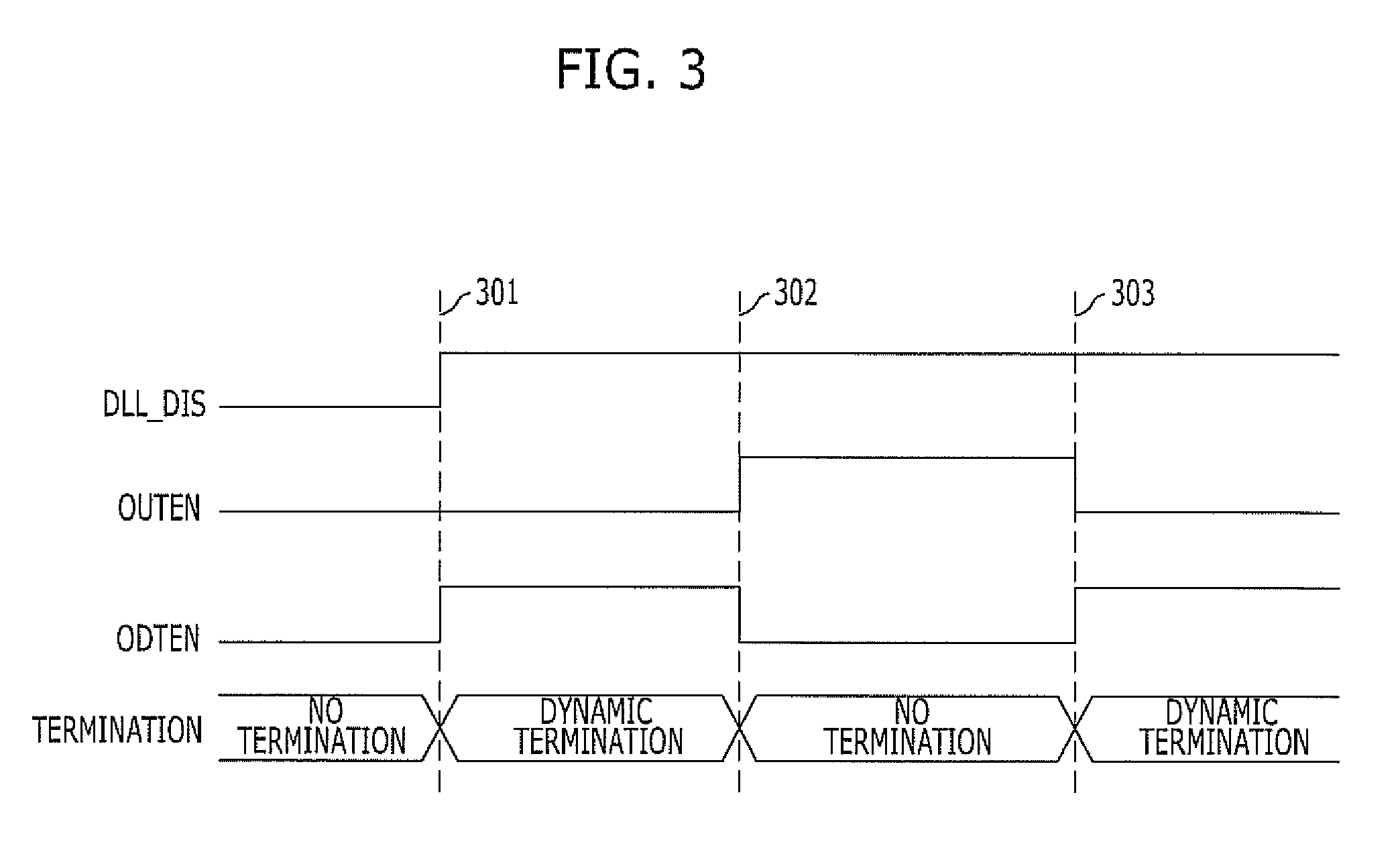

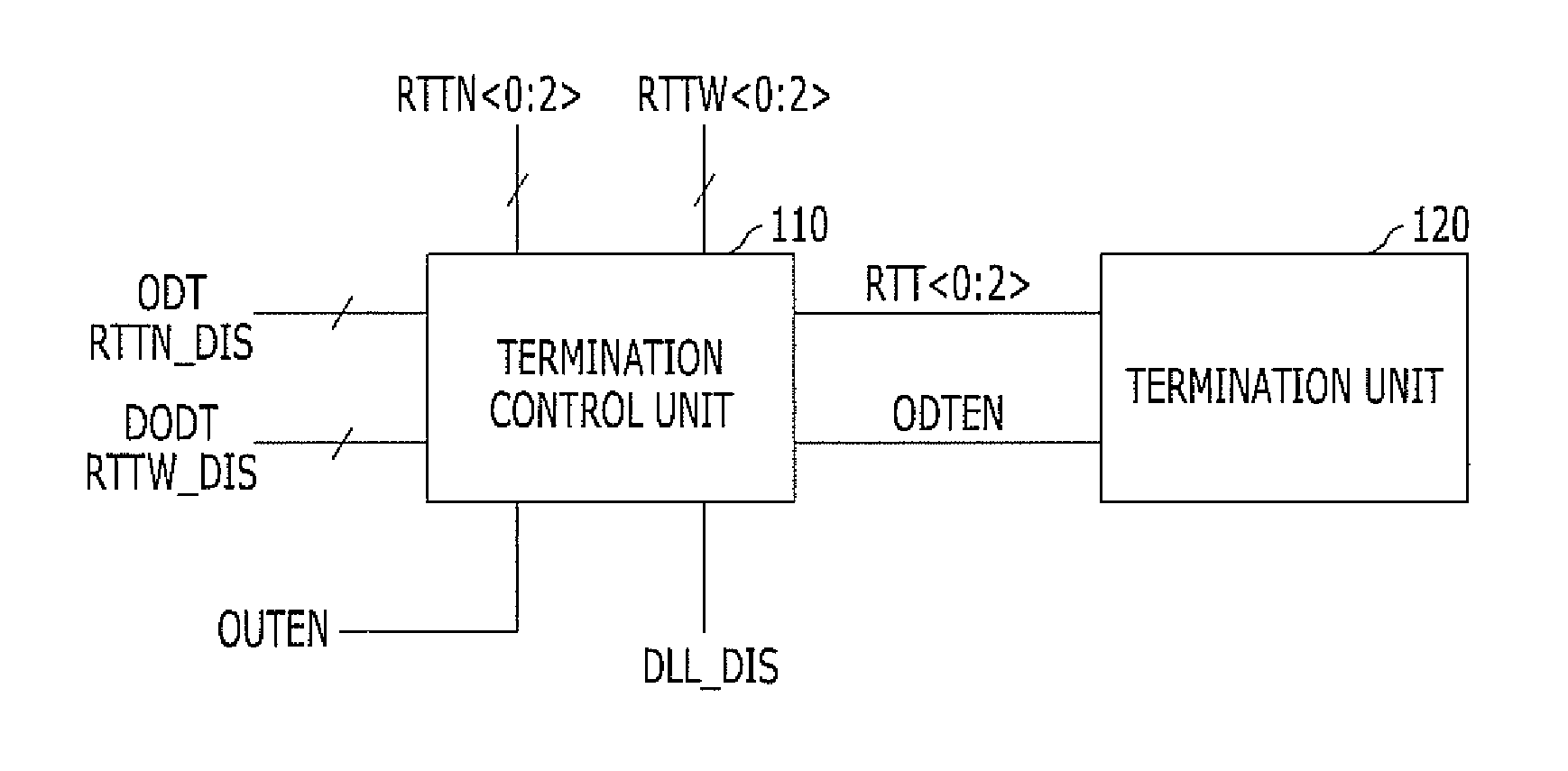

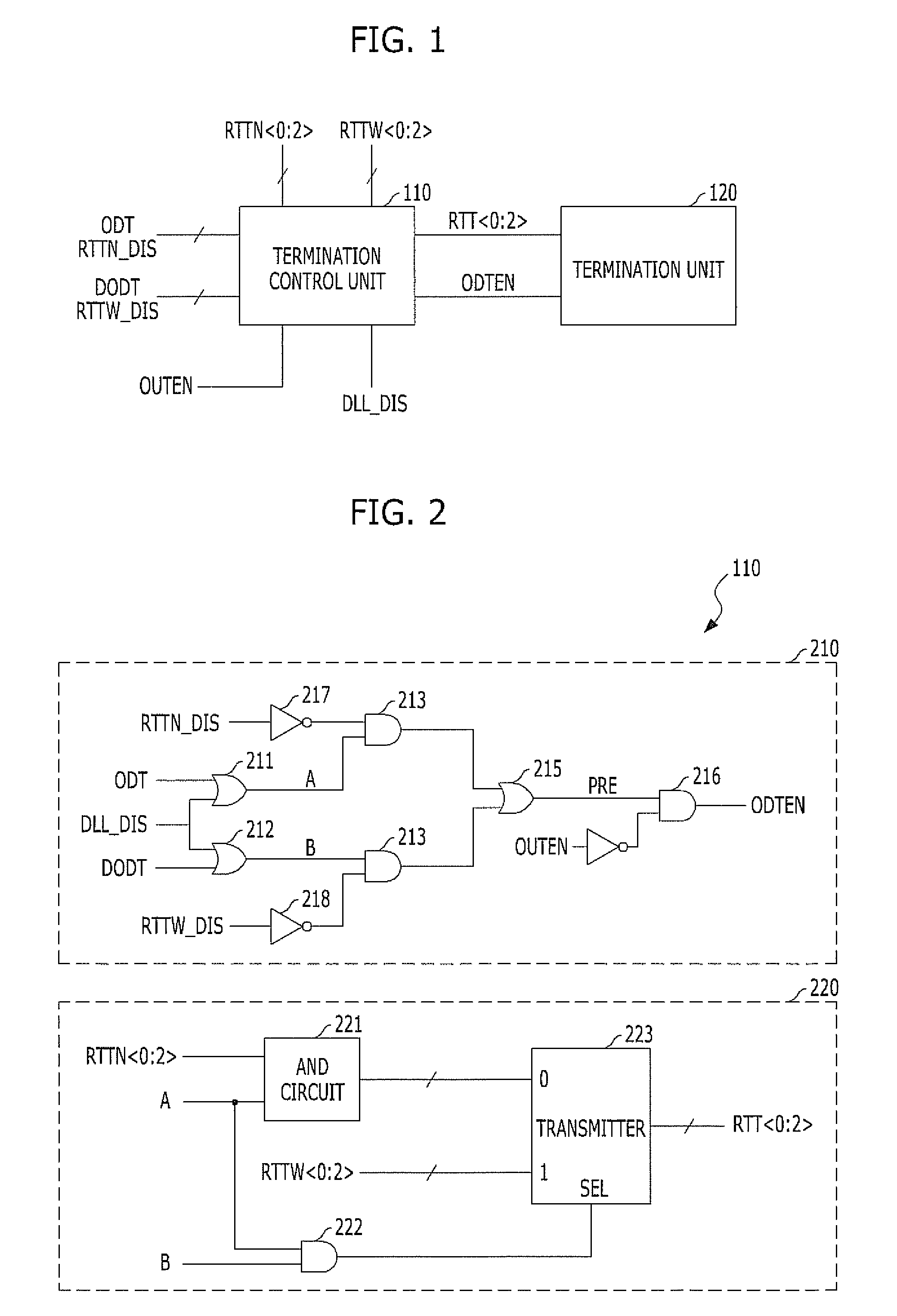

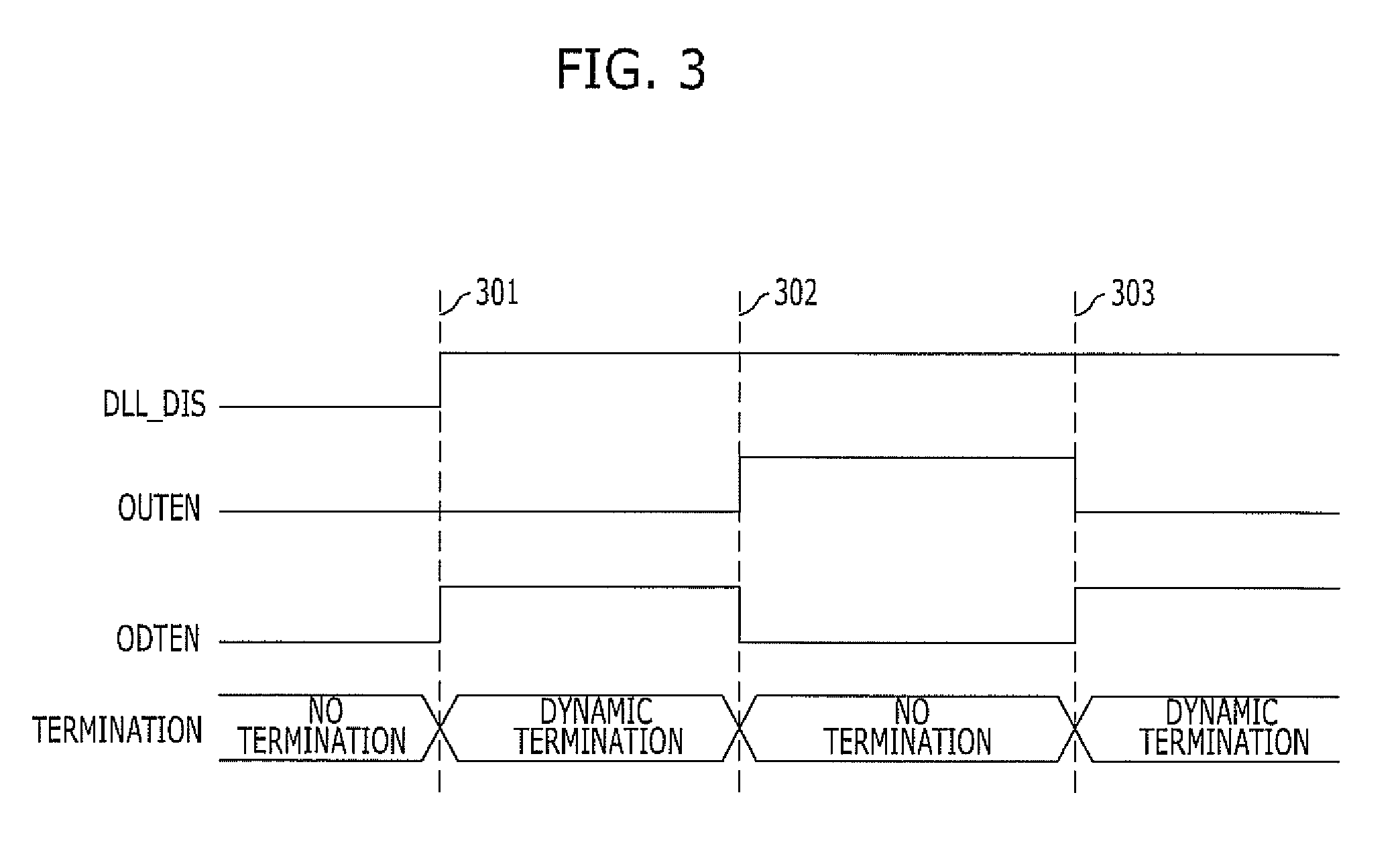

Termination control circuit and semiconductor device including the same

ActiveUS20120217990A1Input/output impedence modificationReliability increasing modificationsPower semiconductor deviceNormal resistance

The semiconductor device includes a termination control unit configured to generate a termination enable signal and termination resistance information in response to termination activation information, dynamic activation information, normal resistance information, and dynamic resistance information wherein the termination enable signal is activated when a delay lock loop is inactivated, and a termination unit configured to be controlled in response to the termination enable signal and terminate an interface pad by using a resistance value determined by the termination resistance information.

Owner:SK HYNIX INC

Quench protection circuit for superconducting magnet coils

ActiveUS8583201B2Improve the immunityCurrent is limitedSuperconductors/hyperconductorsMagnetic field measurement using superconductive devicesElectricityElectrical resistance and conductance

A superconducting magnet includes at least one superconducting coil and a quench protection circuit electrically coupled to said at least one coil in parallel. The circuit includes at least one quench heater assembly thermally coupled to the at least one coil, and at least one superconducting current limiter electrically connected in series with the at least one quench heater assembly. The superconducting current limiter has a superconducting state with zero resistance, and a normal state with a normal resistance to decrease an electric current flowing through the quench heater assembly.

Owner:GENERAL ELECTRIC CO

Semiconductor device

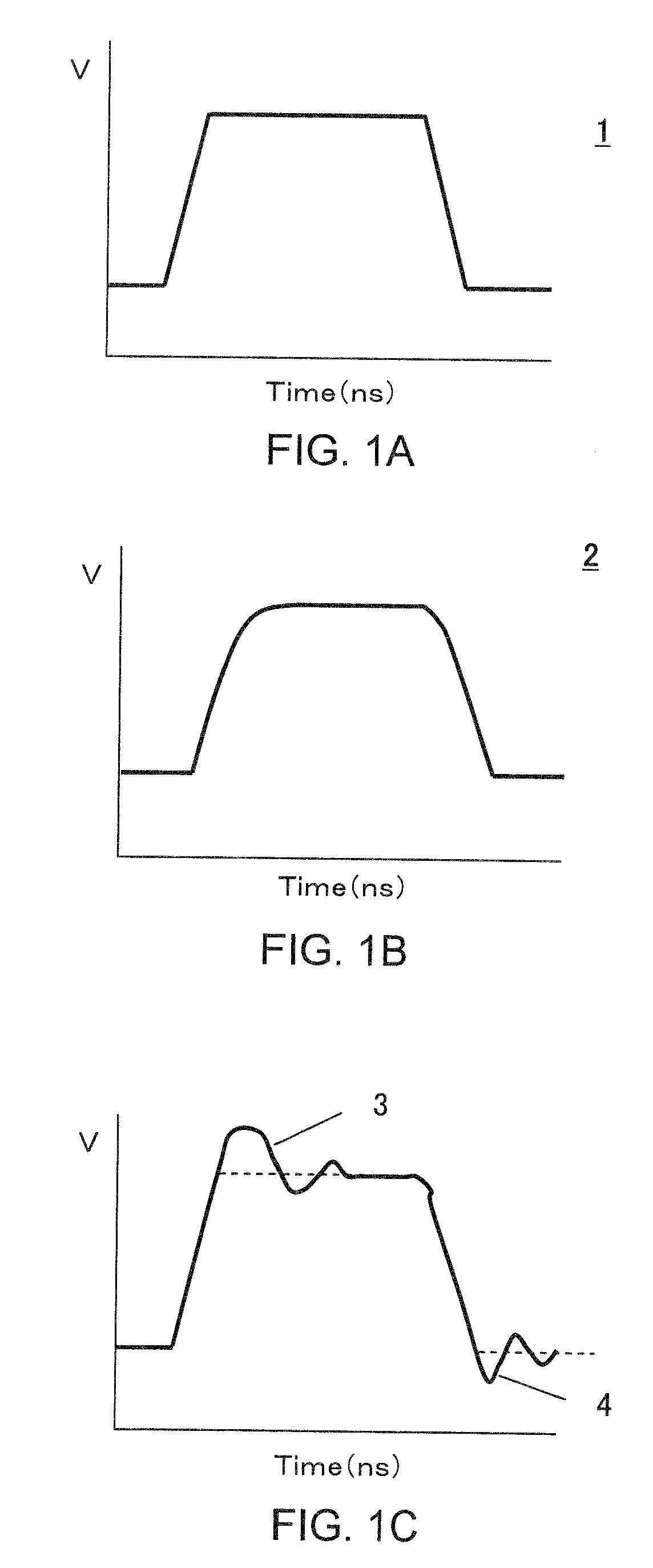

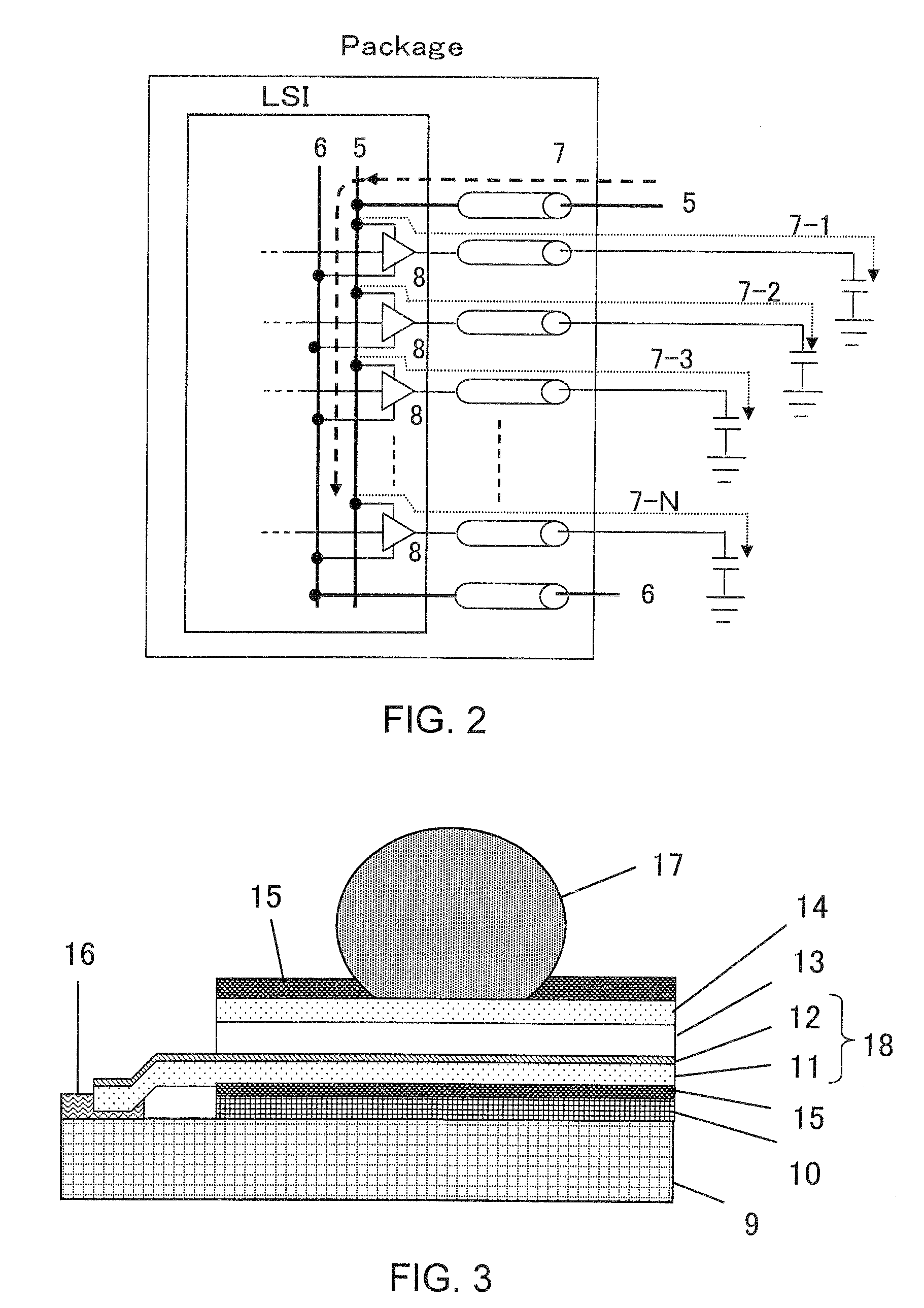

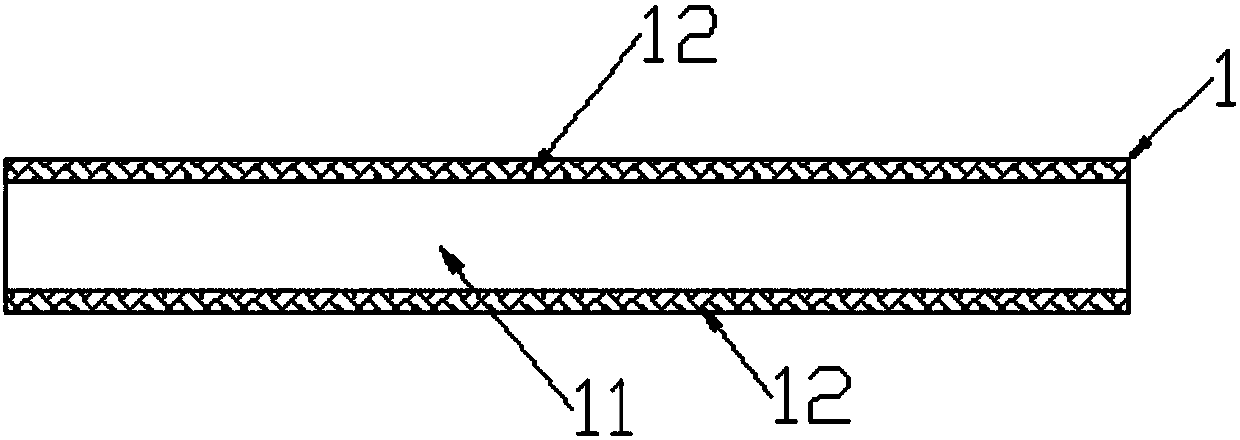

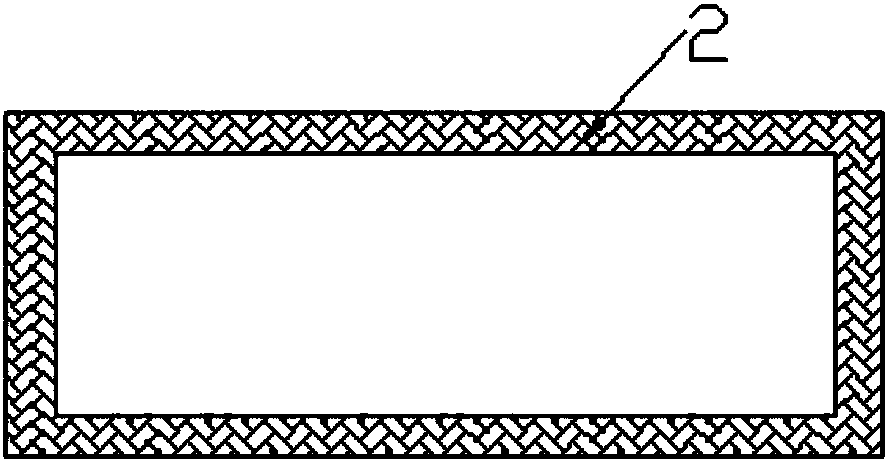

InactiveUS20080164585A1Reduce signal noiseImprove noise reductionSemiconductor/solid-state device detailsSolid-state devicesHigh resistanceElectrical resistance and conductance

A semiconductor device is mounted on a package substrate which has a power supply line and a signal line formed of a normal or predetermined resistance material layer on a dielectric layer. A resistance material layer has a high resistance as compared with the normal resistance material layer and is additionally provided on the surface of the normal resistance material layer of the peripheral face of the signal line closest to the power supply line.

Owner:ELPIDA MEMORY INC +1

High-stability thermistor manufacturing process

ActiveCN107705944AImprove reliabilityImprove stabilityEnvelope/housing resistor manufactureFinal product manufactureNormal resistanceCopper foil

Owner:KUNSHAN SUHANG CIRCUIT BOARD

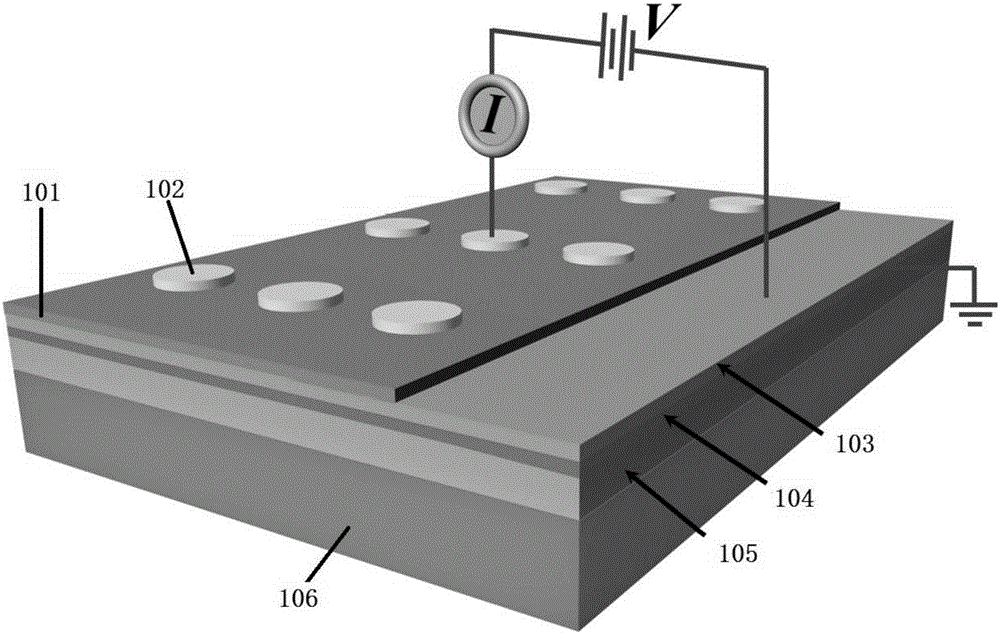

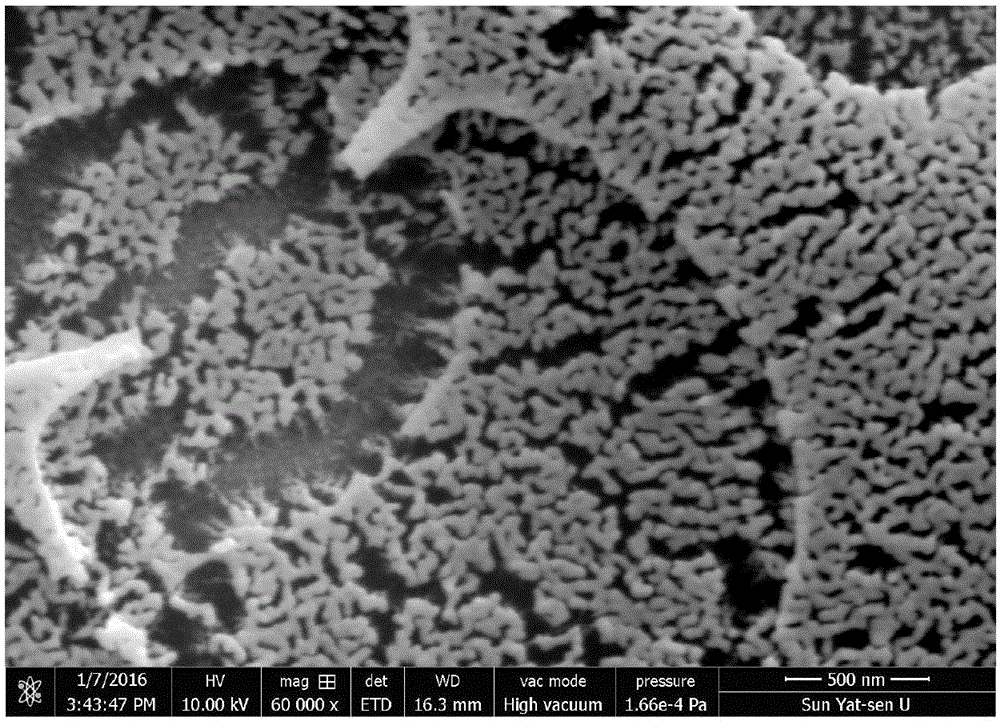

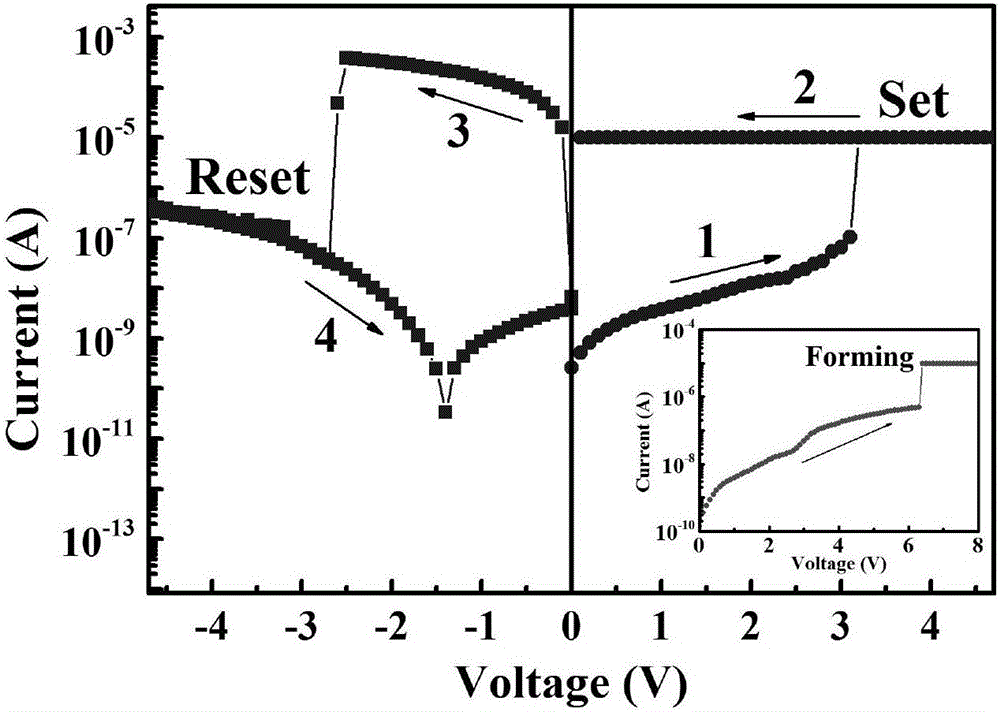

Resistance switch memory based on organic ferroelectric film and preparation method thereof

ActiveCN106252509ASimple ingredientsEasy to prepareElectrical apparatusElectrical resistance and conductanceNormal resistance

The invention provides a resistance switch memory based on organic ferroelectric P (VDF-TrFE) film. The resistance switch memory comprises a substrate, a variable-resistance dielectric layer on the substrate and an electrode film on the variable-resistance dielectric layer. The variable-resistance dielectric layer is a P (VDF-TrFE) film. The invention also provides a method for preparing the resistance switch memory. By controlling the sol-gel preparation, spin-coating speed and annealing conditions, a resistance switch memory with excellent performance can be obtained. The main growth conditions related to the invention are: selection of solvent, stirring speed and temperature, standing time, spin-coating speed, a substrate, and annealing time and conditions. Compared with a normal resistance switch, the resistance switch memory is characterized by big resistance variation, circulation and excellent fatigue performance. Raw materials required for preparation of the P (VDF-TrFE) film are simple; the preparation operation is convenient and easy to control; crystallization of the product is good; preparation temperature is low; and the P (VDF-TrFE) film is nontoxic, environmentally-friendly, and suitable for large-scale production and can be widely used for electronic devices, especially for resistance switch memories.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

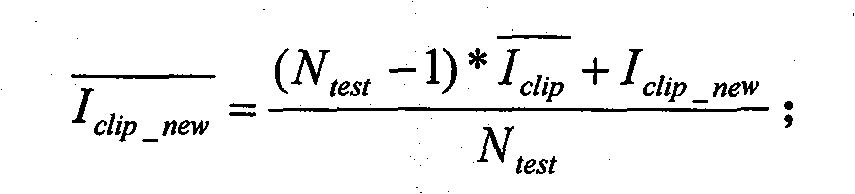

Vehicle window drive clamping-proof control system

InactiveCN101148965BHigh anti-pinch precisionStable jobWindowsWindscreensNormal resistanceMultiway switching

The present invention is squeeze preventing automobile window driving system and control method, and relates to squeeze preventing automobile window driving technology. The system includes one microprocessor circuit, one intelligent feedback power chip, one multiway switch detection interface circuit, one window top touch switch, one test switch, one window bottom touch switch, one window ascent switch and one window descent switch connected together. The control method includes the following steps: for the microprocessor circuit to detect braking current value for N times and normal resistance current value for N times and to store the calculated threshold value in a flash memory; to compare with the reference current value in the flash memory, and to rotate the motor inversely to execute the squeeze preventing function if the calculated threshold value is greater. The present invention has high antipinching precision and capacity of automatically updating threshold value with operation of the automobile window.

Owner:HARBIN INST OF TECH

Termination control circuit and semiconductor device including the same

ActiveUS8610457B2Input/output impedence modificationReliability increasing modificationsNormal resistanceDelay-locked loop

Owner:SK HYNIX INC

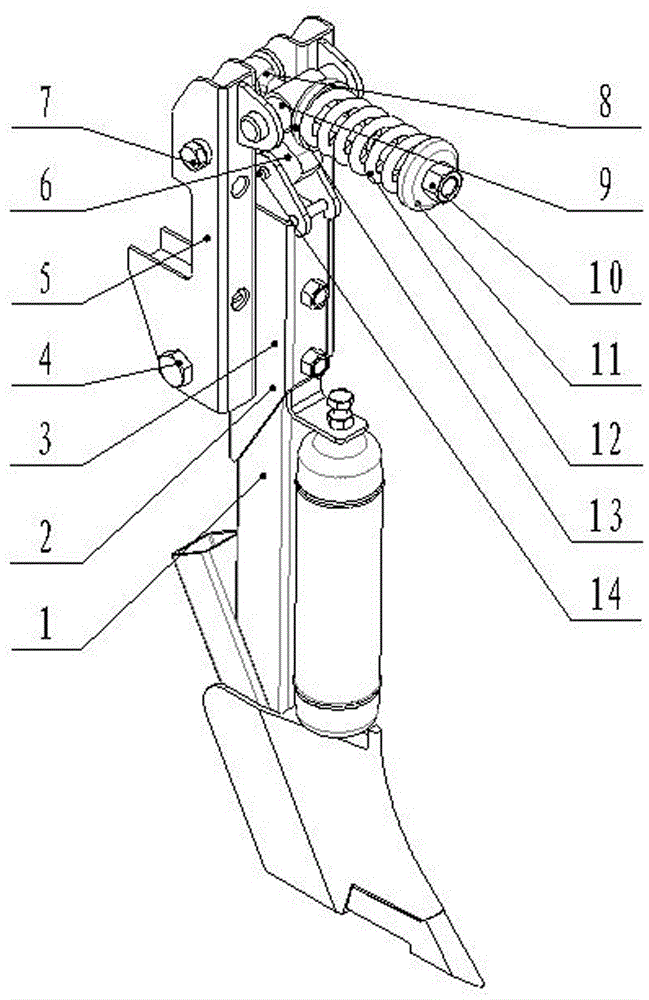

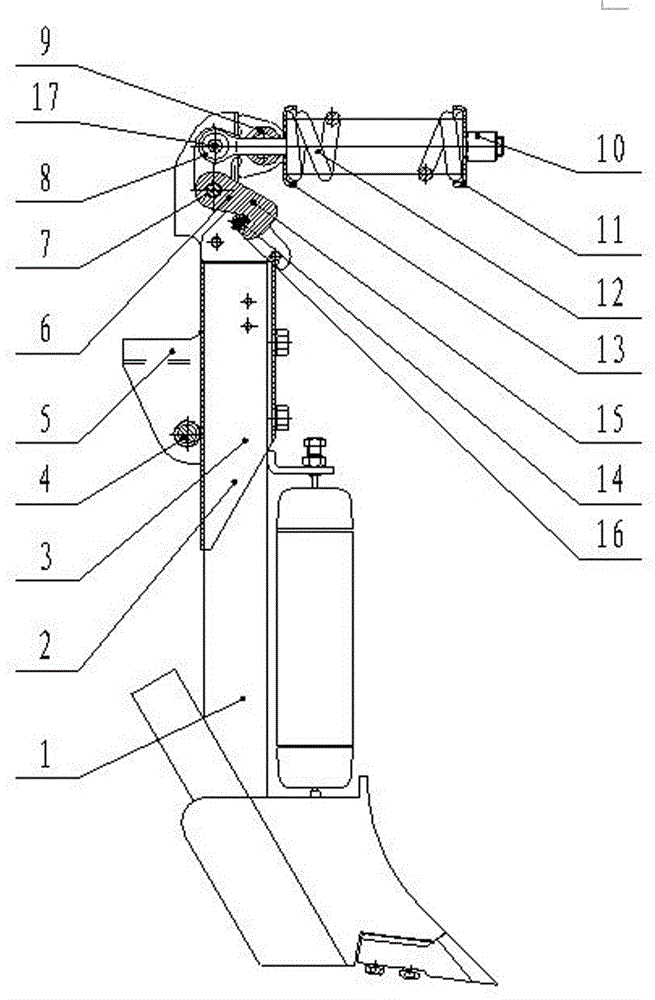

Furrow opener overload protection device

ActiveCN106489369AGuaranteed to workPlantingFurrow making/coveringNormal resistanceAgricultural engineering

The invention provides a furrow opener overload protection device, and relates to the technical field of agricultural machinery. The furrow opener overload protection device comprises a furrow opener and a mounting seat, wherein the mounting seat comprises a base capable of being fixed on a rack, a rotary sleeve lever, a hook lever and a spring; the furrow opener is mounted on a power arm under the rotary sleeve lever; a shaft is arranged on a resisting arm above the rotary sleeve lever; an inclined plane hook is arranged at a power arm end under the hook lever and is matched with the shaft; a resisting arm end above the hook lever is connected with the spring. The furrow opener overload protection device provided by the invention overcomes defects in the prior art; the furrow opener not only can ensure normal work under normal resistance when the furrow opener works in a no-tillage hard land, but also can cut off load borne by the furrow opener when the furrow opener encounters abnormal resistance and before the furrow opener is damaged by the abnormal resistance so as to achieve a purpose of protecting the furrow opener.

Owner:HEBEI NONGHAHA MASCH GRP CO LTD

Thermal treatment method for railway wagon sliding chute wearing plate and side frame column wearing plate

ActiveCN102676753BImprove heat treatment effectUniform heat treatment hardnessFurnace typesDraw-gearPotassium nitrateNormal resistance

The invention discloses a thermal treatment method for a railway wagon sliding chute wearing plate and a side frame column wearing plate. The thermal treatment method is characterized by comprising at least the following steps of: (1) heating: tidily placing the wearing plates in a loading frame, and heating in a normal resistance furnace, wherein the heating temperature is 20-30 DEG C higher than that of the normal process, full fusion of total elements in a workpiece into a matrix structure is facilitated, and uniform and consistent hardness after quenching is guaranteed; (2) quenching in a nitrate bath tank of 260-300 DEG C other than in conventional water or oil, wherein the formula of a nitrate bath comprises 50 percent of potassium nitrate and 50 percent of sodium nitrate respectively; and adding 1-5 percent of water before quenching according to different materials and sizes of the wearing plates, wherein the isothermal cooling time in the nitrate bath tank is 45-90 minutes according to different sizes of the wearing plates; (3) taking the workpiece out of the nitrate bath tank, draining the residual nitrate bath and cleaning residual salt in hot water; and (4) checking hardness and deformation of the workpiece and performing tempering treatment if the hardness is high.

Owner:株洲春华实业有限责任公司

Data collection testing method for electromagnetic valve

The invention discloses a data collection testing method for an electromagnetic valve. The method comprises the steps that: when the electromagnetic valve works, an ARM embedded controller is started to operate a resistance tester to send a resistance value collected at a work end of the electromagnetic valve in real time; and if difference between the resistance value of the work end of the electromagnetic valve and a normal resistance range of the electromagnetic valve in starting or stopping state exceeds a preset value, a voice alarm which is conducted with the ARM embedded controller in a communicated manner is started to point out that the electromagnetic valve has a fault. By adopting the data collection testing method for the electromagnetic valve, disclosed by the invention, in case of start failure or stop failure of the electromagnetic valve, the consequences that due to ignorance of an operator, the whole industrial control process is damaged and severe accidents are caused easily can be prevented.

Owner:XIAN CENTN TECH

Wide stress area silicon pressure sensor

InactiveCN100439887CHigh sensitivityForce measurement using piezo-resistive materialsHigh concentrationPressure sense

This invention belongs to semiconductor pressure sensor technosphere. The sensor includes pressure-sensing film that stressed zone stretched and supporting part around it. voltage dependent resistance lay in high-stress area that cross over pressure-sensing film, compose Wheatstone bridge, to convert pressure change to electrical signal; broken number of the described voltage dependent resistance perpendicular to pressure-sensing film's bound is greater than that parallel to pressure-sensing film bound, to meet shape of high stress region; resistance strip width of turnover section is greater than normal resistance strip width; processing ion implantation of high concentration at the same time to wane ohmic value of turnover section; the pressure-sensing film thickness-width ratio as far as possible large, to satisfy require of bound's high stress region width. The invention is at the condition of chip area reducing but line not reducing, utilize membrane outer region of high stress to increase stressed zone area, to advance sensor sensitivity and reduce numbers of rejects.

Owner:TSINGHUA UNIV

High stability thermistor processing technology

ActiveCN107705944BImprove reliabilityImprove stabilityEnvelope/housing resistor manufactureFinal product manufactureNormal resistanceCopper foil

The invention discloses a high-stability thermistor manufacturing process which comprises the following steps: firstly, manufacturing an inner layer on a thermistor material, performing laser treatment on a side of a gong groove, pressing a prepreg with a copper foil, filling the gong groove with a resin, further performing laser treatment on the other side of the gong groove, pressing the prepregwith the copper foil, filling the gong groove with the resin, wrapping a thermistor inside the gong groove completely, and finally performing patterning, thereby obtaining a finished product of the thermistor. By adopting the high-stability thermistor manufacturing process, the thermistor is manufactured in modes that groove holes are formed through laser and mechanical means and the resin is repeatedly pressed and supplied, the thermistor is surrounded by the resin, very high reliability and stability are achieved, the characteristics that the resistance of a thermistor plate is increased incase of heat and large current and normal resistance is recovered after the heat and the current are recovered are met, then relatively high market requirements are met, and product diversity is achieved.

Owner:KUNSHAN SUHANG CIRCUIT BOARD

Semiconductor device

InactiveUS7944026B2Suppress interferenceImprove signal qualitySemiconductor/solid-state device detailsSolid-state devicesHigh resistanceNormal resistance

A semiconductor device is mounted on a package substrate which has a power supply line and a signal line formed of a normal or predetermined resistance material layer on a dielectric layer. A resistance material layer has a high resistance as compared with the normal resistance material layer and is additionally provided on the surface of the normal resistance material layer of the peripheral face of the signal line closest to the power supply line.

Owner:ELPIDA MEMORY INC +1

Manganese doped negative temperature coefficient singlecrystalline silicon heat sensitive resistance

InactiveCN100358060CLower resistanceNegative temperature coefficient thermistorsSemiconductor materialsHeat sensitive

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

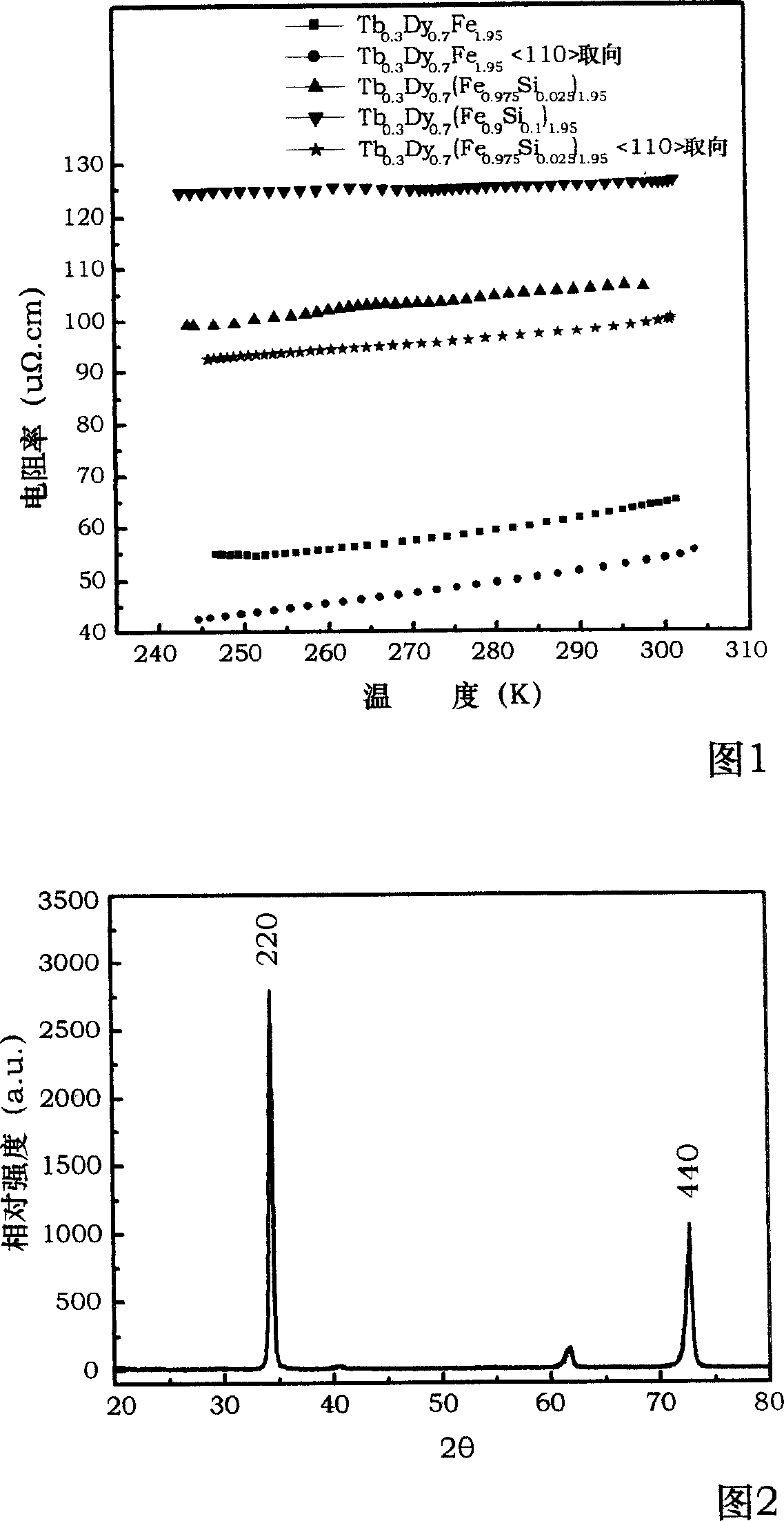

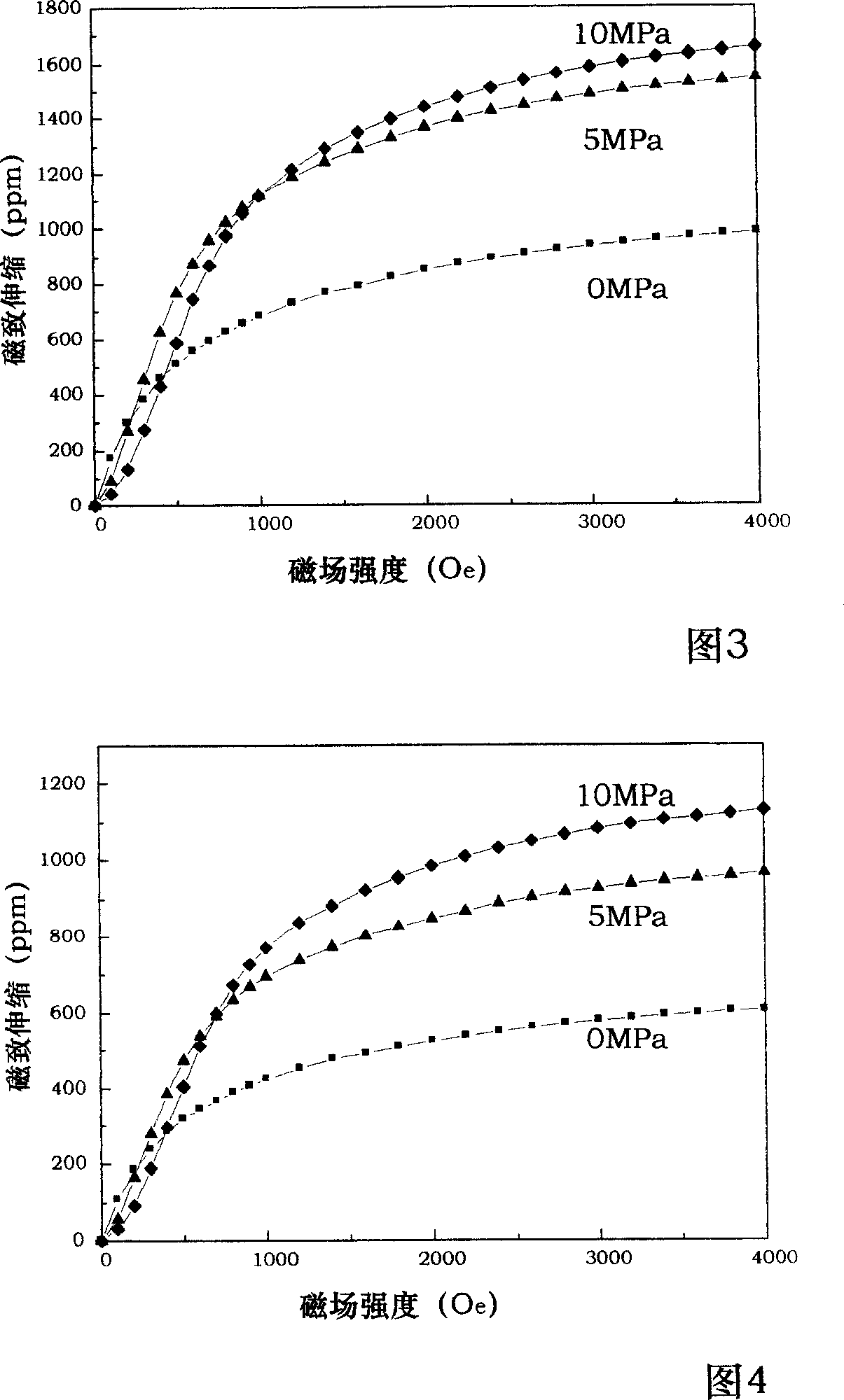

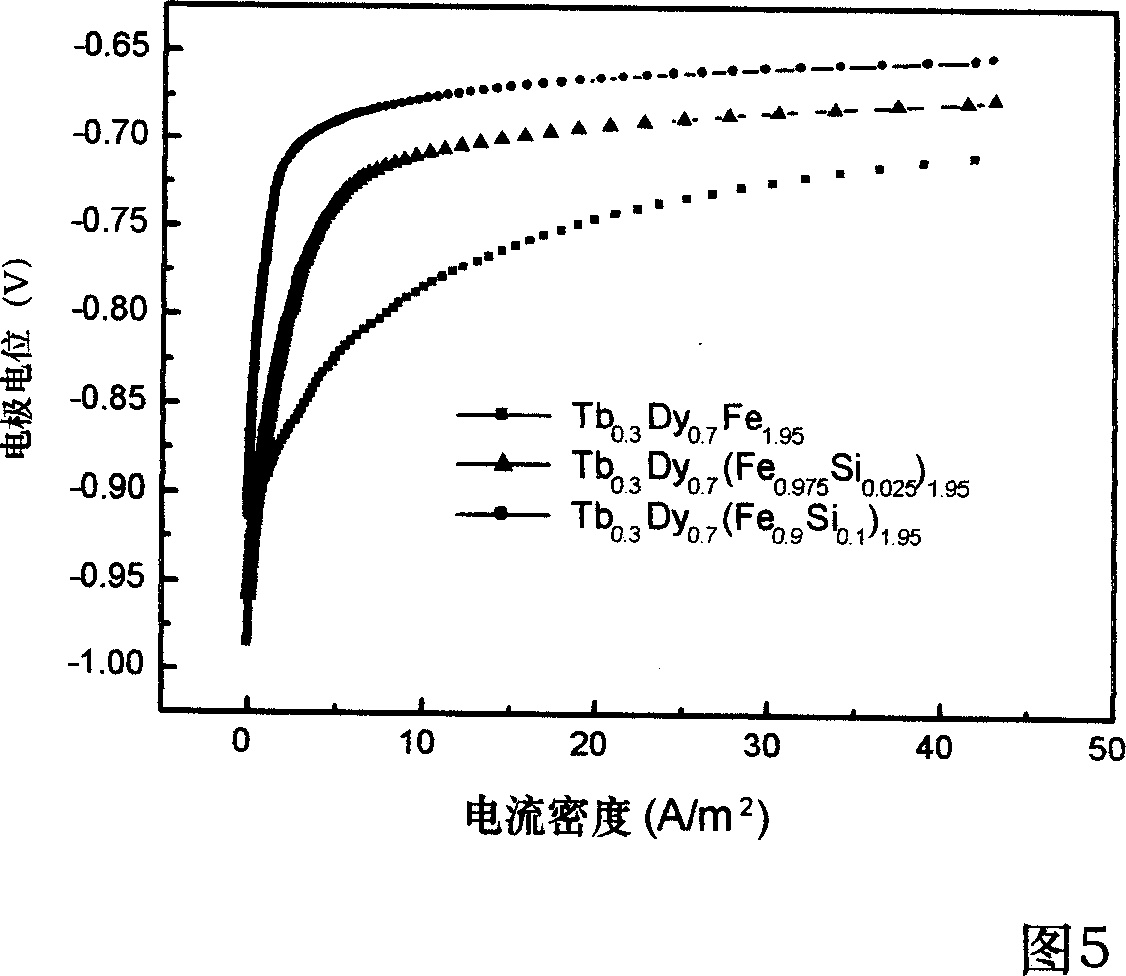

Method for preparing axial preferred orientated corrosion-resistant high-resistance ultra magnetostrictive material

The method to prepare corrosion-resist high-resistance supermagnetostrictive material with axial preferred orientation comprises: adding Si into Tb-Dy-Fe material to improve its normal resistance and corrosion-resist performance; in directional solidification, using the floating zone method with directional solidification speed 240mm / h-900mm / h and temperature gradient 500-900Deg / cm at 1500-1900Deg to prepare the material. In 400mT additional magnetic field and 10MPa prestress, this material has magnetostriction up to 1100-1700ppm and corrosion resistance improved 2-8% in 3.5% NaCl solution.

Owner:BEIHANG UNIV

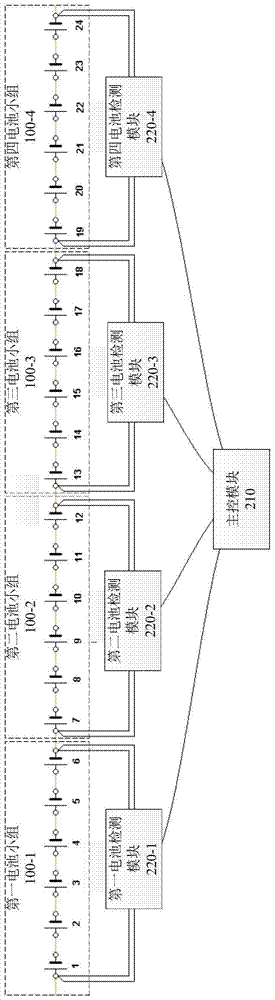

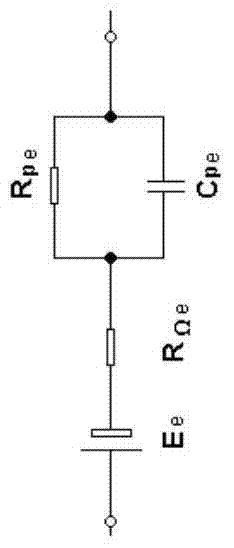

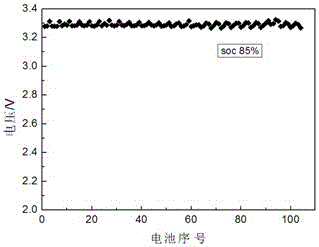

A device and method for quickly testing and evaluating the quality of a storage battery

The invention relates to a device and method for quickly testing and evaluating the quality of a storage battery. The storage battery is a battery pack composed of multiple single cells connected in series. The battery pack is further divided into a plurality of adjacent single cells. A battery group formed in series; the device includes a main control module and a plurality of battery detection modules communicating with it; each battery detection module is connected to a battery group in the battery group to obtain the measured value of the performance parameter of each battery group; The main control module is used to compare the measured value of the performance parameter of each battery group with the normal value of the performance parameter corresponding to the number of single batteries of the battery group, and when the measured value of the ohmic resistance is greater than the normal value, and the When the measured value of the capacitance is less than its normal value, it is determined that there is an abnormal battery in the battery group. The invention has the characteristics of fast detection speed and low cost, and can be applied to battery monitoring in power substations, communication base stations, UPS in machine rooms and the like.

Owner:PLUKE TECH

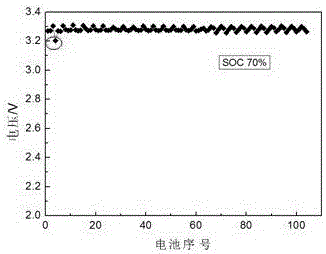

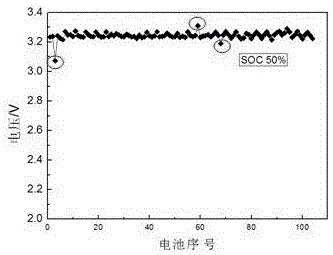

A screening method for secondary use of waste power batteries

ActiveCN103901350BReduce the quantity requiredReduce charge and discharge timesElectrical testingPower batteryNormal resistance

The invention relates to a worn-out power battery secondary use screening method. The whole of a battery pack is charged and discharged, through data recorded by the BMS in a test, in the discharging process, 2 to 4 SOC points with the SOC value ranging from 20% to 90% are selected, and voltage of each monomer in series is read; the batteries which are deviated from most of the batteries and overpass 5% in the voltage value are determined to be batteries of problems, and the residual batteries are initially identified as batteries in healthy states; internal resistance of each battery in the residual batteries is measured, a second screening is conducted through the inner resistance value, battery cells which deviate from normal resistance of the most battery cells by 20% are eliminated and the screening is finished; 10 batteries are randomly selected from the residual batteries to be charged and discharged, the average capacity of the 10 batteries is deemed as the capacity value of all the batteries in the healthy states. Compared with the detection method of the prior art, times of charging and discharging are greatly reduced, time needed by the new screening method is about 1 / 10 less than the traditional method, quantity demand for charging and discharging devices is greatly reduced, and equipment investment is reduced.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com