Wide stress area silicon pressure sensor

A stress area, silicon pressure technology, applied in the field of silicon piezoresistive pressure sensor chips, can solve the problems of inability to manufacture piezoresistor areas, reduce sensor sensitivity, increase processing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

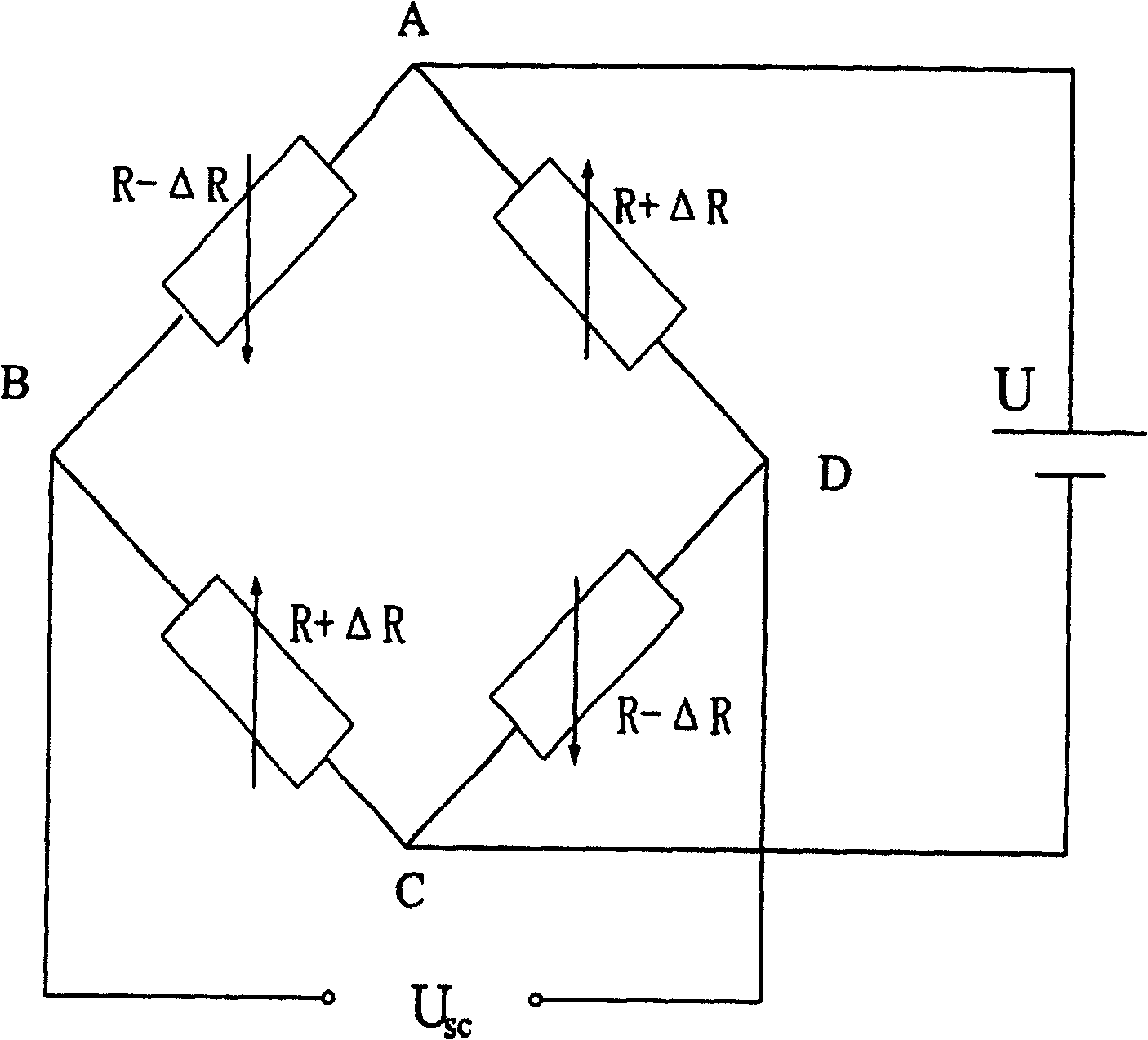

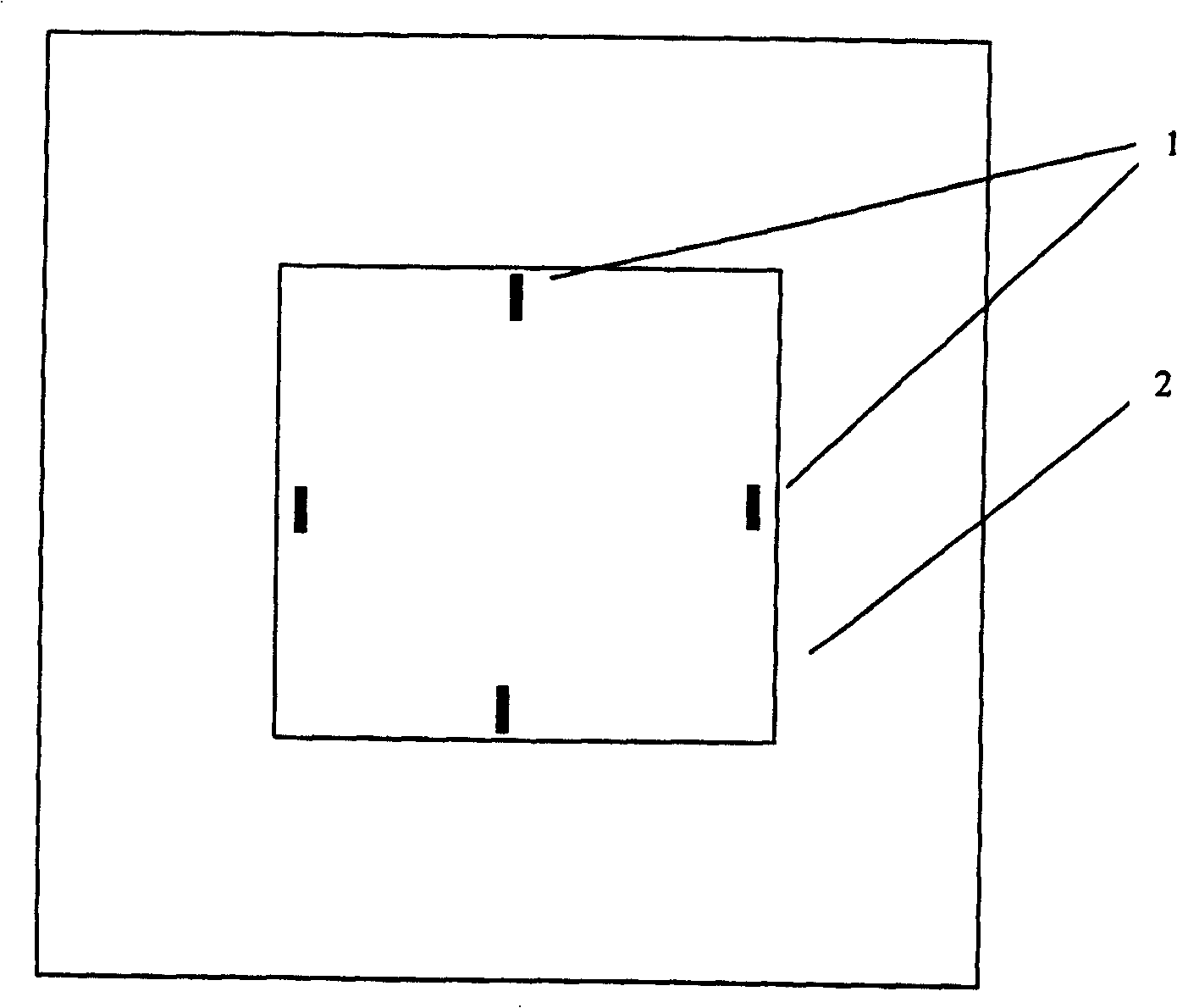

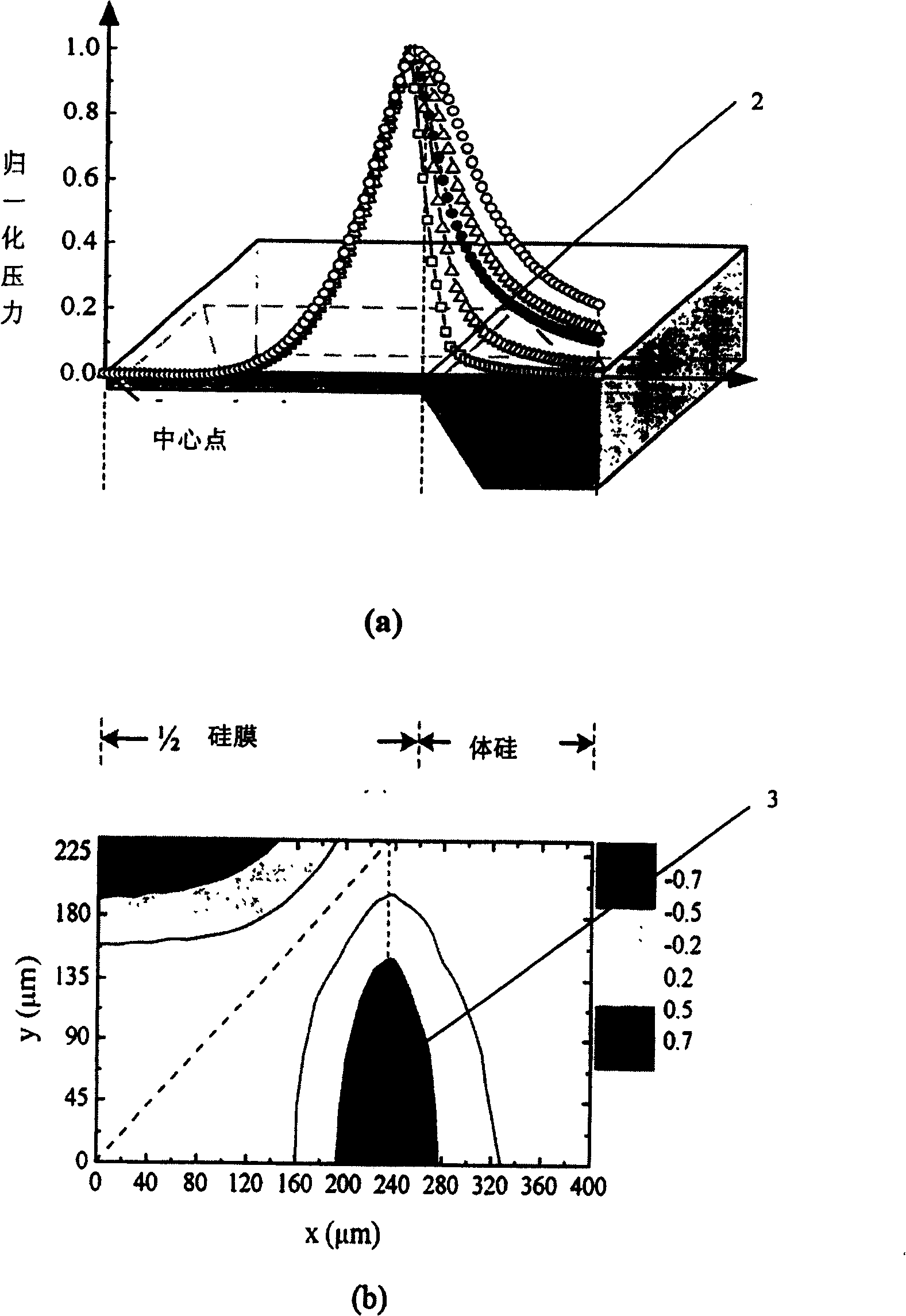

[0017] In order to overcome the improvement of sensor integration and the reduction of chip area, the area of the film is getting smaller and smaller, and the area of the high stress area in the film is also getting smaller and smaller, which cannot provide the area required for manufacturing piezoresistors, resulting in a serious reduction in the sensor. Sensitivity affects the yield; and if the method of narrowing the line is adopted, the difficulty of the process will be greatly increased, and the processing cost will be increased instead. A new type of high-sensitivity silicon pressure sensor chip structure in a large stress region, such as Figure 4 shown.

[0018] The design has the following characteristics: first, the strained film adopts a large thickness-to-width ratio, which greatly expands the stress area outside the boundary; second, in order to make full use of the stress area, part of the resistance crosses the boundary of the film; third, the resistance use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com