A screening method for secondary use of waste power batteries

A power battery and screening method technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effect of reducing the number of charging and discharging, reducing quantity requirements, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe below in conjunction with embodiment.

[0024] Take the Chery M1 pure electric obsolete battery pack as an example, the battery contains 106 cells connected in series, and the rated capacity of the cells is 60Ah. The original battery pack is 339V, 20kwh.

[0025] (1) Connect the disassembled battery pack to the Digalong test cabinet (200A, 500V).

[0026] (2) Charge the entire battery pack at 1 / 3C (20A) to 381V (the number of cells in series multiplied by 3.6, that is, 106×3.6), and then charge at a constant voltage until the current is 0.05C (3A); stand still to the highest The temperature is less than 30°C (if the highest temperature is less than 30°C after charging and discharging, it should be left still for at least 0.5 hours); then discharge at 1 / 3C (20A) to 265V (multiply the number of series cells by 2.5, that is, 106×2.5).

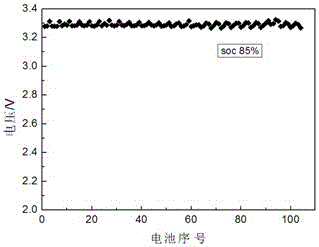

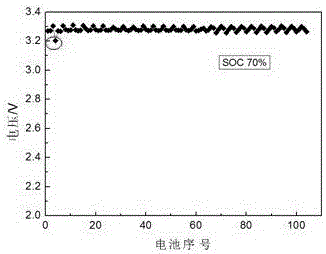

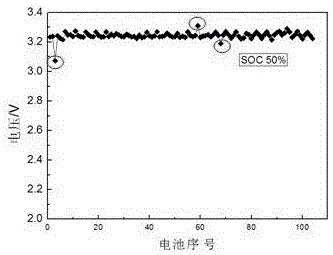

[0027] (3) Through the data recorded by the BMS during the test, during the discharge process, select the SOC (battery state of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com